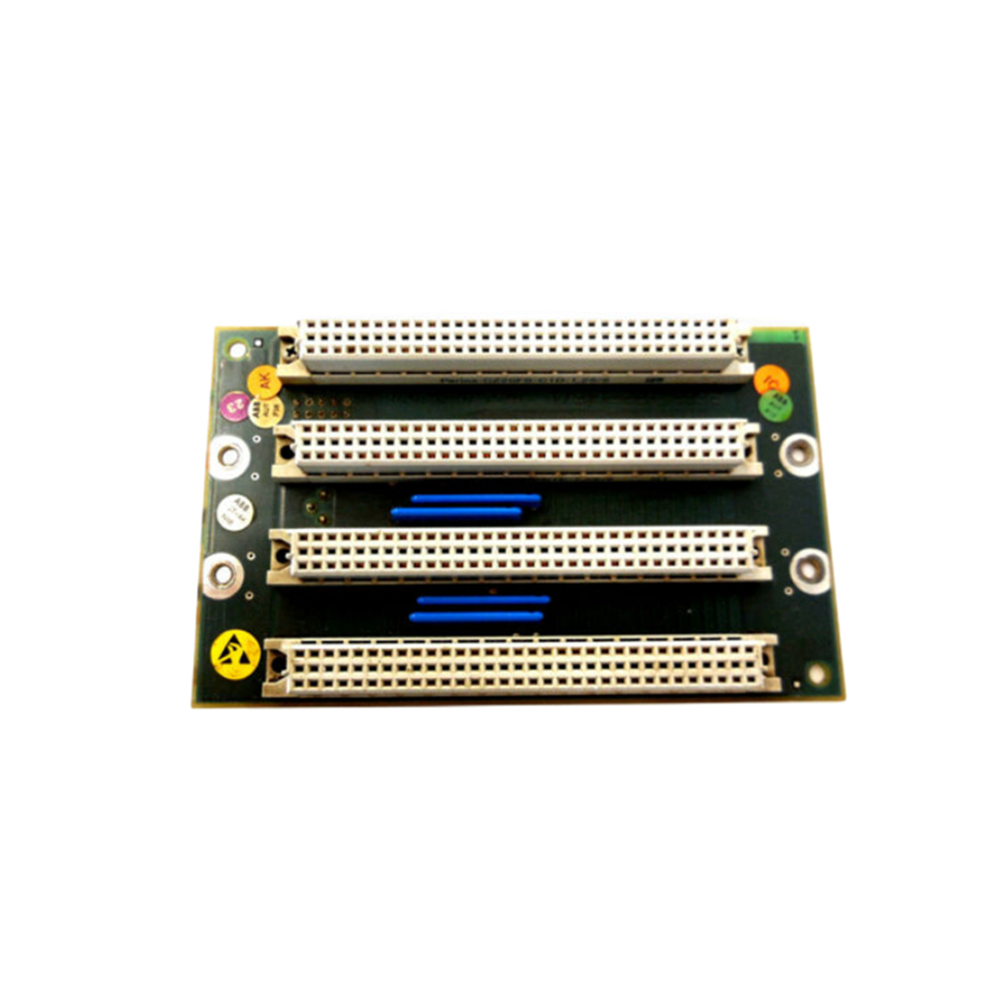

ABB DSBB175: High-performance communication processing module for industrial automation

ABB DSBB175: High-performance communication processing module for industrial automation

Product Overview

ABB DSBB175 is a high-performance communication processing module focusing on industrial automation, which plays a key role in complex industrial control system networks. It can efficiently realise the conversion and data interaction between different communication protocols to ensure stable and fast communication between industrial equipment, and is widely used in industrial scenarios that require high reliability and real-time data transmission, such as large-scale automated production lines and integrated control systems for smart factories. With powerful communication processing capability and stable operation performance, DSBB175 has become an important equipment to improve the communication efficiency and stability of industrial automation system, helping industrial production to achieve intelligent and efficient upgrade.

Technical specifications

Communication interface: Equipped with a variety of communication interfaces, including Ethernet interface (supporting 10/100/1000Mbps adaptive), PROFIBUS DP interface, Modbus RTU interface, etc., which can meet the needs for connection with different industrial equipment and systems, and realise flexible and diversified communication network.

Protocol support: Support TCP/IP, UDP, PROFIBUS, Modbus, CANopen and other industrial communication protocols, able to convert data protocols and efficient communication between devices with different protocol standards, eliminating communication barriers between devices.

Data processing capability: powerful data processing capability, data transmission rate up to 1000Mbps, can quickly process large amounts of industrial data, to ensure real-time transmission of data in the industrial network, to meet the strict requirements of industrial automation systems on data timeliness.

Memory capacity: Built-in large-capacity memory can store a large amount of communication configuration data and historical communication records, which is convenient for users to set parameters and analyse communication data retrospectively, and at the same time, it supports fast data reading and writing operations.

Power supply voltage: 24V DC power supply, stable and reliable power input, good power adaptability, can adapt to the complex and changing power supply environment in industrial sites.

Operating temperature range: stable operation in the extreme temperature range of - 40 ℃ to + 70 ℃, whether it is the cold northern industrial site, or high temperature industrial production plant, can maintain stable working performance, with excellent environmental adaptability.

Protection level: The protection level reaches IP65, with the ability of dustproof and water splashproof, which can effectively resist the dust, rain and other harsh environmental factors in the industrial site, and ensure the reliable operation of the module in harsh industrial environments.

Installation: Supporting both rail mounting and panel mounting, the installation is convenient and flexible, and can be selected according to the actual industrial site layout and equipment installation requirements, saving installation space and improving installation efficiency.

Performance Advantages

Multi-protocol compatibility and conversion: ABB DSBB175 can simultaneously support a variety of industrial communication protocols and achieve rapid conversion between different protocols. In the industrial automation system, devices produced by different manufacturers often use different communication protocols, DSBB175 can be used as a ‘translator’ to allow these devices to smoothly interact with the data, breaking the communication barriers between the devices, and achieving a high degree of integration and collaborative work in the industrial system.

High-speed and stable data transmission: 1000Mbps data transmission rate and advanced data processing technology ensure high-speed and stable data transmission in industrial networks. In large-scale automated production lines, a large number of sensors, actuators and other devices generate data that need to be transmitted and processed in real time, DSBB175 can quickly and accurately transmit these data, avoiding data transmission delays and packet loss phenomenon, to ensure the continuity and stability of the production process.

High Reliability and Stability: With a wide operating temperature range of -40℃ to +70℃ and a high protection class of IP65, DSBB175 is endowed with strong environmental adaptability. It can operate stably even in harsh industrial environments such as high temperature, humidity and dust, reducing the probability of equipment failure due to environmental factors. At the same time, the module adopts high-quality electronic components and rigorous circuit design, which further improves its reliability and reduces maintenance costs and equipment downtime.

Flexible Installation and Configuration: The DIN-rail mounting and panel mounting modes, as well as the convenient parameter configuration interface, make the installation and commissioning of DSBB175 more flexible and efficient. Users can quickly complete the installation of the module and communication parameter settings according to the actual needs, and supports remote configuration and management functions, which is convenient for users to centralise the management and maintenance of modules scattered in different locations.

Powerful data processing and storage: large capacity memory and efficient data processing algorithms enable DSBB175 to quickly process and store large amounts of industrial data. It can not only process communication data in real time, but also store and analyse historical communication data, which provides powerful data support for the optimization of industrial production processes and fault diagnosis.

Note

Power Connection: When connecting the 24V DC power supply, make sure that the power supply voltage is stable and the polarity is correct. It is recommended to use a high-quality power adapter with overload protection and filtering to avoid damage to the module caused by power fluctuations and surges, and to ensure that the power supply is well grounded to improve power safety.

Communication wiring: When wiring the communication interface, it is necessary to operate in strict accordance with the wiring diagram to ensure that the wiring is firm and correct. Use standard communication cables, and according to different communication protocols and transmission distances to choose the right type of cable, such as shielded twisted-pair cable, etc., and at the same time do a good job of cable grounding to reduce the impact of electromagnetic interference on the communication signal.

Environmental requirements: Although DSBB175 has a high level of protection and a wide range of operating temperatures, but still should try to avoid placing it in the installation of strong electromagnetic interference near the source, such as large motors, frequency converters and other equipment. If it can not be avoided, effective electromagnetic shielding measures should be taken, such as the use of shielded cabinets, electromagnetic shielding devices, etc., to ensure the stability of the module communication.

Software Configuration and Update: Before using the module, the communication protocol, IP address, port number and other parameters should be correctly configured according to the actual industrial application requirements. During the configuration process, the parameter settings should be carefully checked to avoid communication abnormalities caused by parameter errors. At the same time, pay regular attention to the official software update information released by ABB, and upgrade the module's firmware and drivers in a timely manner in order to obtain better performance and new functions, and enhance the compatibility and stability of the module.

Comparable Models

ABB DSBB180: Compared with DSBB175, DSBB180 may have further improvement in communication processing performance, such as supporting more kinds of communication protocols, or having greater breakthroughs in data transmission rate and processing capacity, which can meet more complex and demanding industrial automation communication scenarios. In terms of the type and number of interfaces, DSBB180 may be increased to adapt to the connection needs of more devices and improve the scalability of the system.

ABB DSBB170: As a simplified version of the DSBB175, the DSBB170 is relatively weak in terms of functionality and performance. It may support a smaller variety of communication protocols, and its data processing power and memory capacity are also relatively small. However, its advantage lies in its lower cost, which makes it suitable for small industrial automation projects that do not require particularly complex communication functions, limited budgets, or simple industrial scenarios that do not require high communication performance .

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor