Honeywell Experion PKS Series C I/O

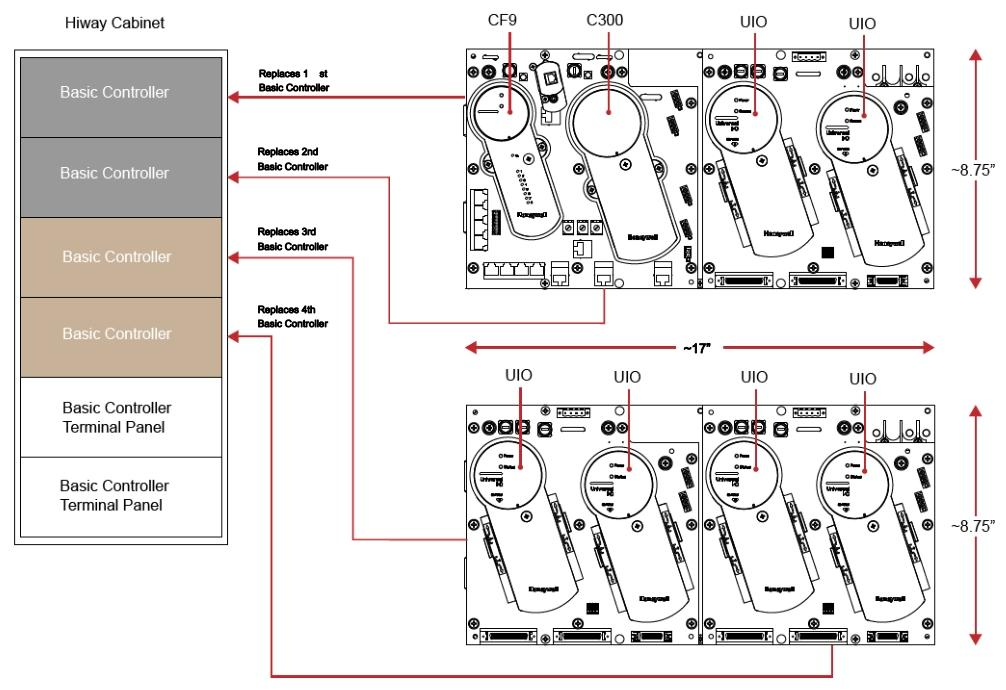

Series C I/O Definition: It is a series of traditional and special function input/output signal interface devices that support local software configuration, share the same external specifications with the C300 controller, and use the same installation system.

Series C I/O Mark II: It is an enhancement of the existing Series C platform in terms of IO modules, related IOTA, IO links, power supply, distribution, and cabinet infrastructure, making it more cost-effective. The design style remains unchanged, but it does not support any PM I/O.

Series C Pulse Input Module (SCPIM): capable of high-precision pulse counting, with 8 input channels, some of which can be configured as dual inputs, and the last 2 channels can also be configured as fast cut-off outputs. It has multiple functions and is different from Series A PIM in terms of external specifications, redundancy support, and other aspects.

Connection with other devices: Introduces the connection methods with ST500 dual pulse simulator, dual current devices, other sensor types, as well as input threshold selection and recommended cable types.

Series C Universal Horizontal Input/Output (UHIO) Components

Introduced the system and grounding audit checklist for horizontal C300/CF9 IOTA, horizontal UHIO IOTA, I/O connectors, TDC 2000 system, UHIO components, installation, general regulatory compliance, COTS AC-DC power supply, protective grounding, and environmental characteristics.

Universal Input/Output (UIO) module for rail installation

Advantages: Low space consumption, high cost-effectiveness, and simple component relocation.

Physical description: Introduces the composition of the components and the model, size, weight, and other information of some components.

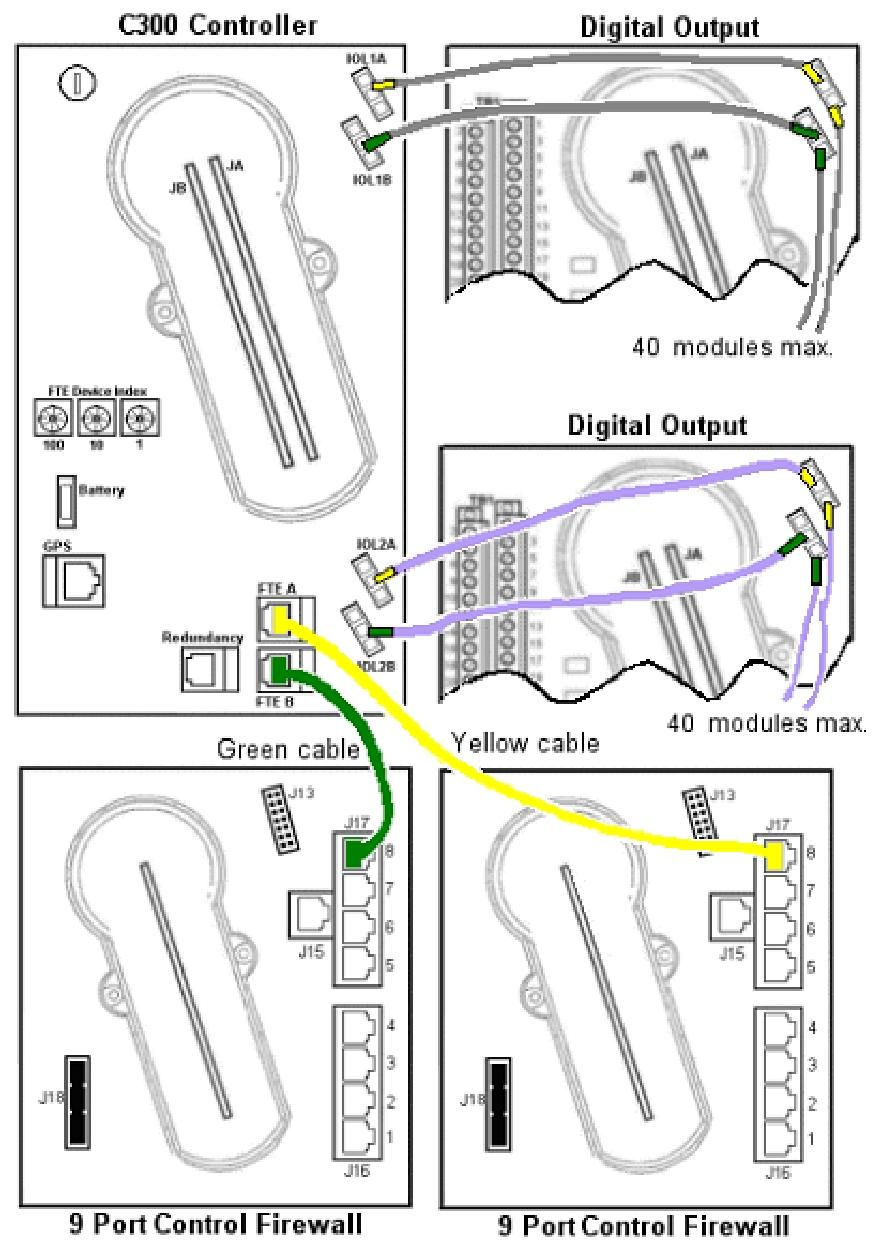

Input/Output Link (IOL) Management: Supports specific UIO IOTA versions and DIN rail installations, and introduces relevant cables.

Single mode FOE: It is a necessary component for installing UIO on rails, and its component options, installation positions, etc. are introduced.

System wiring: It demonstrates the end-to-end connection of UIO modules installed on rails in a single cabinet and adjacent cabinets.

Power requirements: Powered by a+24VDC remote industrial grade power supply, including voltage range, power consumption, related protection, wiring, fuse terminal blocks, and circuit breakers.

Institutional certification: Possessing certifications such as CE, CTick, HAZLOC, etc.

Environmental conditions: Clearly defined environmental parameters such as temperature and humidity for work and storage.

Module assembly, installation, connection, disassembly: Detailed introduction of relevant steps and precautions.

Replaceable spare parts: lists the models and names of some replaceable spare parts.

Reference for Series C I/O Configuration Form

Determine redundancy: IOM blocks represent hardware instances of I/O modules, configurable redundancy, and generate system events and alerts.

Switching and secondary readiness: Switching is the process of a secondary module becoming a primary state, and the readiness state of the secondary module determines whether it can take over control functions.

Fault conditions and switching: Some faults may cause switching, such as primary module power failure, while others may not.

Configuration tool: Creating control policies using the Expert Control Builder requires multiple operations, and the IOM must be present during configuration loading.

Each tag configuration: detailed introduction Main、Server History、Server Displays、Control Confirmation、Identification、QVCS、Calibration、HART Status The parameter configuration method and content of the waiting tab.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor