Watlow MLS300 Series Controller

Watlow MLS300 Series Controller

Product basic positioning and core features

1. Product positioning

The MLS300 series is a multi loop PID controller, available in two versions: 16 loop (MLS316) and 32 loop (MLS332), supporting thermocouples RTD、 Multiple sensor inputs such as linear voltage/current and pulse can achieve independent or linked control of process parameters such as temperature, pressure, and flow rate. The system adopts a modular design, compatible with multiple expansion modules (such as DAC/SDAC analog output modules), supports EIA/TIA-232/485 serial communication, can be connected to upper computer or PLC systems, and complies with CE and UL standards ®/ C-UL ® Certification and EU EMC Directive (EN 61326).

2. Core advantages

Advantages Category Specific Characteristics Value Explanation

Multi loop control single device supports 16/32 independent PID loops, each loop can be configured with heating/cooling dual outputs to reduce the number of devices, reduce panel space occupation, and adapt to multi zone process scenarios (such as multi-stage extruders and large ovens)

Flexible input compatibility supports J/K/T/S/R/B/E type thermocouples, 100 Ω platinum RTD (2/3 wire system), 0-20mA/4-20mA current, 0-12V voltage, and pulse input (up to 2kHz) to reduce spare parts inventory and adapt to sensor requirements of different processes without the need for additional signal conversion modules

Advanced control function supports cascade control, proportional control, remote simulation set point, and differential control (enhanced firmware); Ramp/Soak batch control (optional firmware) to meet complex process requirements (such as temperature pressure linkage in chemical reaction vessels, staged temperature control for material aging testing)

High reliability built-in sensor fault detection (open circuit/short circuit/reverse connection), power failure protection, CPU watchdog; Supports storing and calling 8 job programs to shorten troubleshooting time, avoid process abnormalities, and adapt to switching between multiple varieties and small batch production

System composition and hardware architecture

1. List of core components

Component Name, Model/Specification, Function and Function

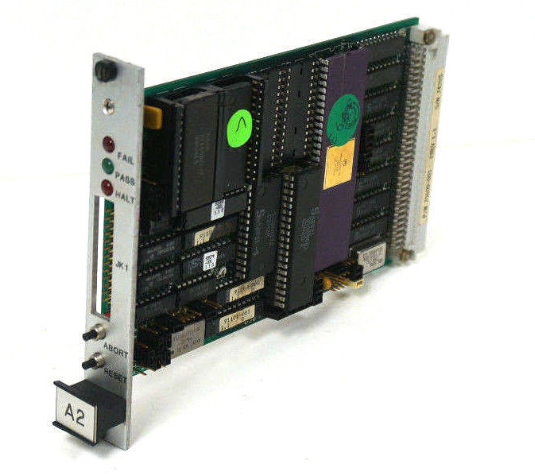

Processor module (PM) MLS300-PM system core, including CPU, 2-line 16 character fluorescent display screen, 8-key keyboard, responsible for data calculation, loop control, and communication management

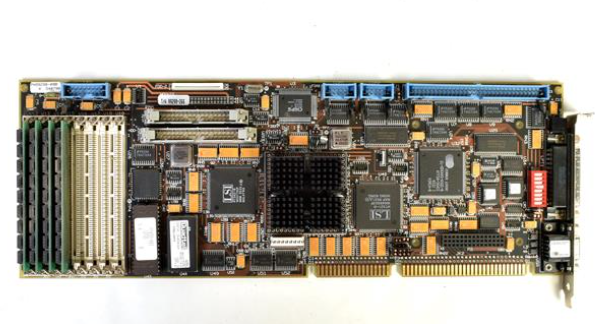

The Analog Input Module (AIM) MLS300-AIM-16 (16 channels)/AIM-32 (32 channels) receives sensor signals, completes signal conditioning and A/D conversion, and communicates with the processor module through RJ45 cables

Compact Input Module (CIM) CIM316 (16 channels)/CIM332 (32 channels) high-density input module, using D-Sub 50 connector to reduce installation space and adapt to high integration scenarios

Terminal board (TB50) MLS300-TB50 50 50 pin SCSI interface terminal board, used for digital I/O, power and control output wiring, supports DIN rail or bracket installation

Expansion Module - DAC (Digital to Analog Converter): 2-channel configurable 4-20mA/0-5V/0-10V output

-SDAC (Serial Digital to Analog Converter): 1 high-precision analog output, supporting process variable retransmission to convert digital output to analog signal, suitable for analog control equipment such as valves and frequency converters

The MLS300-PS power module inputs 120/240V AC and outputs 15V DC/1.2A and 5V DC/4A, providing isolated power supply for the system

2. Hardware architecture logic

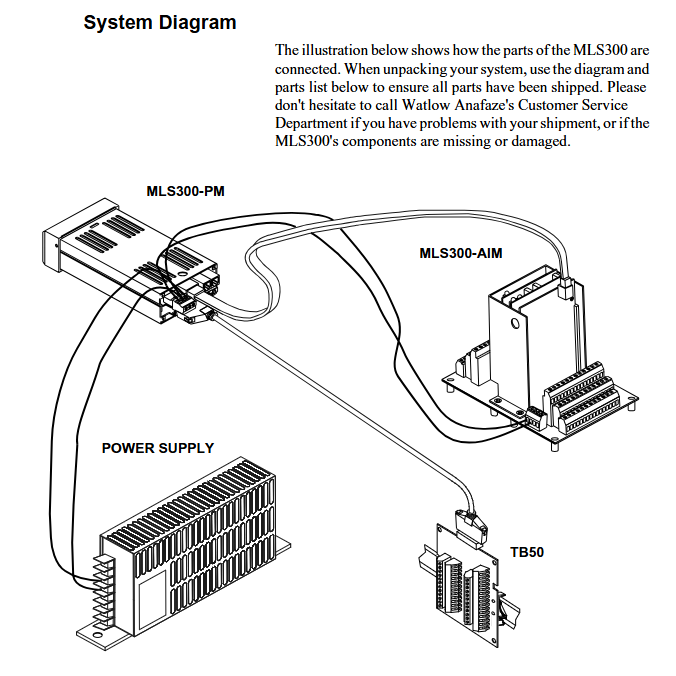

The system adopts a "master-slave" communication architecture, and the data flow is as follows:

Perception layer: Sensors (thermocouples/RTDs, etc.) transmit process signals to the AIM/CIM module, completing signal conditioning and A/D conversion;

Control layer: The processor module (PM) receives digital signals from AIM/CIM, generates control instructions through PID algorithm, and sends them to the TB50 terminal board;

Execution layer: TB50 transmits instructions to actuators such as solid-state relays (SSRs) and contactors to control heating/cooling equipment;

Monitoring layer: Implement parameter settings, status monitoring, and alarm processing through the front-end panel or upper computer (such as WatView software).

Key technical parameters

1. Input parameters

(1) Sensor support and accuracy

Input Type Range Accuracy (25 ℃ environment) Remarks

Thermocouple (Type J) -212~760 ℃ (-350~1400 ℉) ± 1.1 ℃ with cold end compensation, linearization, and open/short/reverse detection

Thermocouple (Type K) -268~1371 ℃ (-450~2500 ℉) ± 1.3 ℃-

RTD1 (high precision) -100~275 ℃ (-148~527 ℉) ± 0.35 ℃ (25 ℃) 0.1 ℃ resolution, only supported by MLS304/308

RTD2 (Wide Range) -120~840 ℃ (-184~1544 ℉) ± 0.9 ℃ (25 ℃) 1 ℃ resolution, only supported by MLS304/308

Linear current 0-20mA/4-20mA ± 0.03% full range requires external scaling resistor

Linear voltage 0-5V/0-10V/0-12V ± 0.03% full-scale-

Pulse input 0-2kHz resolution 0.006% used for encoder speed measurement (such as conveyor belt speed control)

(2) Input performance

Sampling rate: MLS316 is 1.5 times/second (60Hz), MLS332 is 0.75 times/second (60Hz);

Noise suppression: Common mode rejection ratio (CMR)>85dB at 60Hz, input filtering configurable (0-255 scan period);

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc