Yokogawa Motor YS1700 Programmable Indicator Controller

Standard models are smaller and lighter than earlier series,requiring less space for installation, and are compliant with international safety standards including the CE Mark and FM,CSA nonincendive (optional) approvals. For easy replacement of earlier controllers, models requiring the same panel cutout dimensions and depth as those of earlier models are also offered.

Hardware specifications and environmental adaptability

1. Input and output electrical parameters

Signal type specification parameter accuracy requirements

Analog input (1-5V) input resistance 1M Ω, range 0-5.5V, supports direct input (mV, thermocouple, RTD, etc.) ± 0.1% range (basic type), ± 0.2% range (extended I/O)

Analog output (4-20mA) load resistance 0-750 Ω, output range 0.8-21.0mA ± 0.2% range

Digital input with no voltage contacts (below 200 Ω/above 100k Ω), voltage contacts (low -0.5-1V/high 4.5-30V), minimum pulse width of 70-220ms (according to control cycle)

Digital output transistor contact, open circuit output in case of 30V DC/200mA (resistive load) fault

Transmitter power supply 25-25.5V DC, load below 60mA (including 30mA below direct input) short circuit protection 80 ± 10mA

2. Environmental and mechanical characteristics

Working conditions: temperature 0-50 ℃, humidity 5-90% (non condensing), altitude below 2000 meters, atmospheric pressure 86-106kPa; Anti vibration (5-14Hz amplitude 0.625mm, 14-150Hz acceleration 4.9m/s ²), anti impact (49m/s ², within 11ms).

Protection and material: Basic panel protection IP54, shell 316 stainless steel; Insulation resistance 100M Ω (500V DC), withstand voltage 1000-3000V AC (depending on model), in compliance with IEC/EN 61010 safety standards.

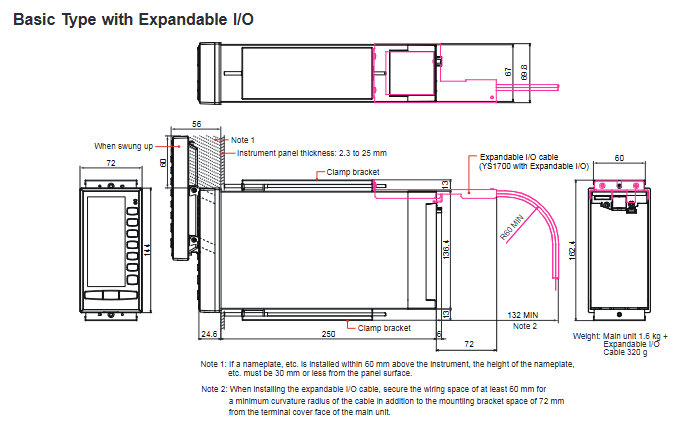

Size and Installation: The basic size is 144 × 72 × 250mm (H × W × D), with a panel opening of 137 × 68mm. It supports parallel installation, and the opening width needs to be adjusted according to the quantity when installing multiple devices (such as 2 units of 140mm and 3 units of 212mm).

Safety Compliance and Certification

General safety standards: comply with IEC/EN 61010-1/2-201/2-030, CAN/CSA-C22.2 No.61010 series standards, overvoltage category II, pollution level 2, measurement category O.

EMC standards: EN 61326 Class A, EN 55011 Class A Group 1, anti common mode noise 83dB, series mode noise 46dB (50/60Hz).

Hazardous Area Certification: Optional FM/CSA non flammable certification (Class I, Division 2, Groups A-D, Temperature Class T4), suitable for potentially explosive environments.

Environmental standards: Compliant with the EU RoHS directive (EN IEC 63000), with no harmful substances except for the A08 frequency input option.

Installation and Accessories

1. Installation requirements

Panel installation: The panel thickness is 2.3-25mm, with at least 60mm of space reserved at the top (to avoid obstruction during operation), and 100mm of ventilation space reserved above and below.

Expansion I/O installation: The expandable I/O type requires YS010 expansion terminals and YS011-03 expansion cables (3 meters), with a cable bending radius of ≥ 60mm.

Wiring specifications: The signal terminal and power terminal are both M4 screws. Shielded twisted pair cables are required for analog signals, and grounding must comply with Yokogawa grounding specifications.

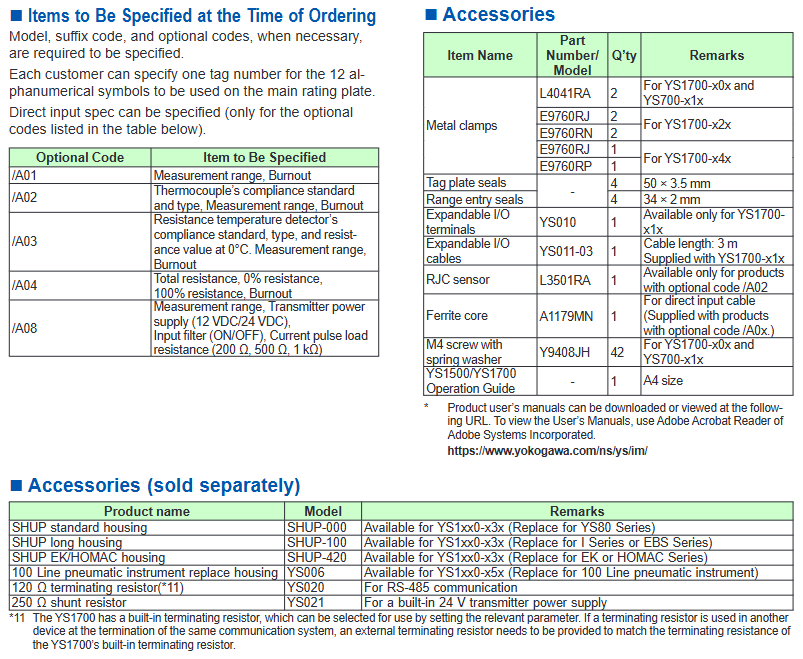

2. Standard and optional accessories

Accessory type, model, purpose, and remarks

Install brackets L4041RA, E9760RJ, and other fixed controllers onto the panel to adapt to different compatible controllers of different models

Expansion I/O accessories YS010 (terminal), YS011-03 (cable) are only applicable for expandable I/O type signal expansion YS1700-x1x

Temperature compensation accessory L3501RA (RJC sensor) thermocouple input reference compensation only/A02 option applicable

YS020 (120 Ω terminal resistor) and YS021 (250 Ω shunt resistor) resistor accessories are suitable for RS-485 communication matching and signal conversion. The terminal resistors can be enabled or not by parameter selection

Replace the shell SHUP-000/SHUP-100/SHUP-420, YS006 to adapt to the installation of old equipment, such as YS80 and 100 line instruments, and select the corresponding shell according to the compatible model

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor