This filter cartridge is a specialized accessory developed by ABB for industrial fluid filtration needs. It belongs to high-precision filter elements, and its design and production strictly follow ABB's globally unified quality standards to ensure perfect compatibility with corresponding ABB equipment models, avoiding filtration failure or equipment damage caused by compatibility issues.

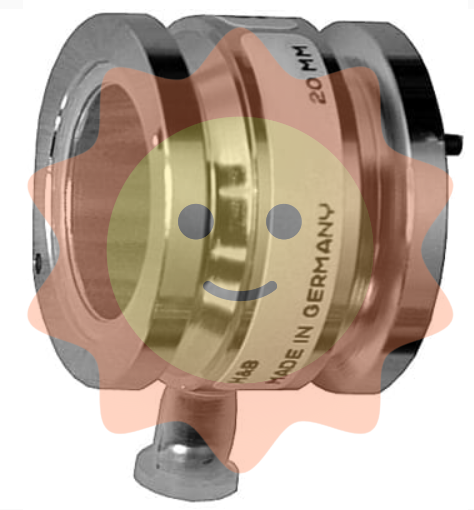

ABB 769154 A filter element

Basic Product Information

This filter cartridge is a specialized accessory developed by ABB for industrial fluid filtration needs. It belongs to high-precision filter elements, and its design and production strictly follow ABB's globally unified quality standards to ensure perfect compatibility with corresponding ABB equipment models, avoiding filtration failure or equipment damage caused by compatibility issues.

-Model: 769154 A

-Filtering accuracy: typically 5-20 μ m (can be matched with corresponding accuracy level according to actual working conditions)

-Material: the filter material is high-strength glass fiber or polyester fiber, and the shell is made of engineering plastic or metal, acid and alkali resistant and anti-aging

-Applicable fluids: hydraulic oil, lubricating oil, coolant, and some industrial media (specific to be confirmed based on fluid characteristics)

-Working temperature: -20 ℃ -120 ℃ (for normal working conditions, please consult the manufacturer for special environments)

Core performance advantages

1. High precision filtration ensures fluid cleanliness

The filter element adopts a gradient filtration structure, and the fiber arrangement of the filter material is tight and orderly, which can efficiently capture solid particles, impurities, and pollutants in the fluid, with a filtration efficiency of over 95%. By accurately intercepting small impurities, it effectively avoids problems such as component wear and oil blockage caused by pollutants entering the equipment, and reduces the occurrence rate of equipment failures.

2. Stable circulation performance, reducing energy loss

While ensuring filtration accuracy, the filter element reduces fluid resistance by optimizing the flow channel design. Even during long-term use, it can maintain a stable flow rate, avoid increased equipment power consumption due to excessive pressure loss, and balance filtration efficiency and energy-saving needs.

3. High strength structure, extending service life

The filter material is made of high-strength materials that are wear-resistant and tear resistant, and the outer shell is treated with special processes to have good compressive and impact resistance. In complex industrial conditions, it can effectively resist fluid impact and environmental pressure changes, and is less prone to problems such as filter material damage and shell deformation. Under normal use, its service life is extended by 20% -30% compared to ordinary filter cartridges.

4. Environmentally friendly adaptation, in compliance with industrial standards

The product material complies with environmental standards such as EU RoHS, and there is no release of harmful chemicals. It will not cause pollution to fluid media and the environment during use. At the same time, its structural design facilitates subsequent recycling and processing, in line with the modern industrial green production concept.

Applicable scenarios and equipment

ABB 769154 A filter cartridge is widely used in the following industrial fields and equipment due to its universal adaptability and stability performance:

1. Industrial hydraulic system: Suitable for ABB hydraulic stations, hydraulic machine tools and other equipment, filters impurities in hydraulic oil, and protects core components such as hydraulic pumps and cylinders.

2. Lubrication system: Used for filtering lubricating oil in motors, reducers, and other equipment to prevent wear particles from affecting the lubrication effect and extend the service life of the equipment.

3. Cooling system: Suitable for industrial chillers and cooling circulation systems, it filters impurities in the coolant, avoids blockages in the cooling pipeline, and ensures heat dissipation efficiency.

4. Other specialized equipment: supporting filtration devices for some ABB automated production lines and robot workstations, as well as non ABB brand equipment that meets the installation size and performance requirements of the filter element (parameter compatibility needs to be confirmed in advance).

Key points for replacement and maintenance

1. Replacement cycle

The replacement cycle of the filter element should be determined based on the actual working conditions. It is recommended to refer to the following standards for routine recommendations:

-Normal cleaning conditions: replace every 3-6 months;

-High impurity conditions (such as mining and metallurgical equipment): Replace every 1-2 months;

-When the pressure reading of the equipment increases abnormally (exceeding the normal working pressure by 10% -15%) or the flow rate decreases significantly, it is necessary to immediately check and replace the filter element.

2. Precautions for replacement

-Before replacement, it is necessary to close the relevant fluid circuits of the equipment, release the pipeline pressure, and avoid fluid leakage;

-When disassembling the old filter element, be careful to avoid impurities falling and contaminating the pipeline. Before installing the new filter element, clean the filter element mounting seat;

-Ensure good sealing between the filter element and the mounting seat during installation to avoid bypass leakage, which may affect the filtration effect;

-Before starting the equipment after replacement, it is necessary to exhaust the air in the pipeline to prevent air blockage from causing equipment failure.

3. Daily maintenance

Regularly inspect the appearance of the filter element, and replace it promptly if any damage is found to the outer shell or aging seals are found; Record the usage time and working conditions of the filter element, establish a replacement ledger, and avoid equipment damage caused by forgetting to replace it; When storing unused filter cartridges, they should be placed in a dry, ventilated, and non corrosive environment, avoiding direct sunlight.

Frequently Asked Questions and Answers

Q1: What are the impacts of clogged filter cartridges on equipment?

Answer: Filter blockage can lead to increased fluid resistance and increased power consumption of the equipment; Meanwhile, unfiltered impurities can enter the interior of the equipment, causing component wear and seal damage, and in severe cases, may lead to equipment shutdown and malfunction.

Q2: Can this filter replace other models of ABB filters?

Answer: It is not recommended to use it as a substitute. Different types of filter cartridges have differences in filtration accuracy, size, flow resistance, and other parameters. Alternative use may result in filtration failure or equipment compatibility issues. It is necessary to strictly follow the specified model in the equipment manual when selecting.

Q3: How to deal with leakage during the use of the filter element?

Answer: First, close the device circuit and check the leakage point. If the sealing between the filter element and the mounting seat is poor, the seal can be reinstalled and replaced; If the outer shell of the filter element is damaged, a new filter element should be replaced immediately to avoid fluid contamination.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-