The ABB 769137 C 13CO2-10% 0746919 E detector is a professional detection equipment developed by ABB for monitoring the concentration of 13 carbon labeled carbon dioxide (13CO2) in specific scenarios. This product integrates ABB's advanced sensing technology and data processing algorithms, with high sensitivity, high stability, and strong environmental adaptability. It can accurately capture the concentration changes of 13CO2 gas within the range of 10% volume fraction in the environment, and output reliable monitoring data in real time.

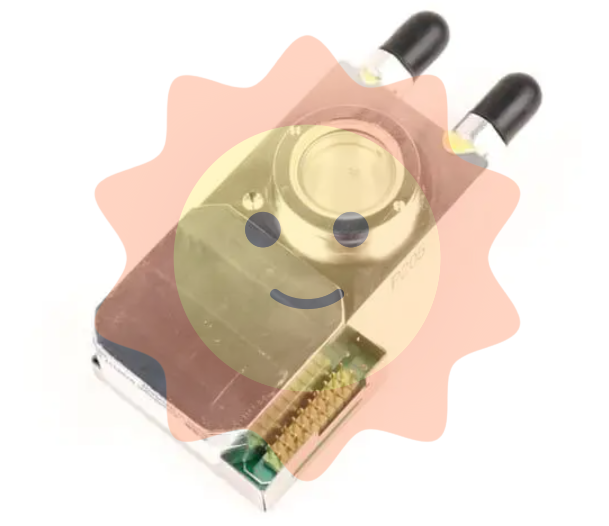

ABB 769137 C 13CO2-10% 0746919 E detector

Product Overview

The ABB 769137 C 13CO2-10% 0746919 E detector is a professional detection equipment developed by ABB for monitoring the concentration of 13 carbon labeled carbon dioxide (13CO2) in specific scenarios. This product integrates ABB's advanced sensing technology and data processing algorithms, with high sensitivity, high stability, and strong environmental adaptability. It can accurately capture the concentration changes of 13CO2 gas within the range of 10% volume fraction in the environment, and output reliable monitoring data in real time.

Unlike conventional carbon dioxide detectors, this device is specifically optimized for 13CO2, a specific isotope gas. It has shown outstanding performance in fields such as biomedical research, agricultural research, and industrial process control that have strict requirements for gas isotope monitoring. It provides users with efficient and accurate gas concentration monitoring solutions, helping to achieve precise collection of experimental data and safe and controllable industrial processes.

Specification parameters

2.1 Core Monitoring Parameters

-Monitoring gas: 13 carbon labeled carbon dioxide (13CO2)

-Measurement range: 0-10% (volume fraction)

-Accuracy level: ± 0.1% FS (full scale)

-Resolution: 0.01%

-Response time: T90 ≤ 5s (time required from gas contact sensor to 90% stable output value)

2.2 Electrical Parameters

-Power supply voltage: DC 24V ± 10%

-Working current: normal operation ≤ 100mA; peak current ≤ 150mA (at start-up moment)

-Output signal: Standard 4-20mA analog signal; Optional RS485 digital signal (Modbus RTU protocol)

-Load capacity: When outputting 4-20mA, the maximum load resistance is ≤ 500 Ω

2.3 Environmental Parameters

-Working temperature: -10 ℃~50 ℃

-Storage temperature: -20 ℃~60 ℃

-Working humidity: 10%~90% RH (non condensing)

-Protection level: IP65 (shell protection, suitable for indoor and semi outdoor environments)

-Anti interference capability: meets the requirements of GB/T 17626.2-2006 (electrostatic discharge immunity) and GB/T 17626.4-2008 (electrical fast transient pulse group immunity)

2.4 Physical Parameters

-Dimensions: 180mm x 120mm x 80mm (length x width x height)

-Shell material: ABS engineering plastic (flame retardant grade UL94 V-0)

-Installation method: Wall mounted/Pipeline type (optional, Pipeline type requires specialized sampling components)

-Weight: Approximately 0.8kg (excluding installation accessories)

Performance characteristics

3.1 Accurate monitoring and strong targeting

Adopting ABB's exclusive 13CO2 specific sensing technology, it can effectively distinguish 13CO2 from ordinary 12CO2 and other interfering gases (such as methane, carbon monoxide, etc.), avoid measurement errors caused by cross interference, and maintain extremely high monitoring accuracy in complex gas environments, meeting the precise measurement needs of isotope gases in scientific research and industrial scenarios.

3.2 Stable and reliable, with a long lifespan

The core sensor adopts imported components, undergoes strict aging testing and stability calibration, and has an average time between failures (MTBF) of ≥ 50000 hours; The device has built-in automatic calibration function, supporting two modes of timed automatic calibration and manual calibration, which can effectively offset the impact of sensor drift and maintain good performance stability even after long-term use.

3.3 Strong adaptability to the environment

The optimized temperature and humidity compensation algorithm can automatically correct measurement data within a wide range of temperature and humidity, ensuring the accuracy of measurement results during environmental fluctuations; The protection level of IP65 can effectively resist external environmental influences such as dust and rain, and is suitable for various scenarios such as laboratories, industrial workshops, and agricultural greenhouses.

3.4 Convenient operation and simple maintenance

The device is equipped with a small LCD display screen, which can display real-time information such as 13CO2 concentration value, working status, power supply status, etc; The operation buttons are simple and easy to understand, supporting quick operation of functions such as parameter setting and calibration startup; At the same time, the device supports remote data transmission (optional RS485 version), which facilitates users to achieve centralized monitoring and data management through the upper computer system, reducing operation and maintenance costs.

3.5 Safety protection, ensuring comprehensive coverage

The shell is made of flame-retardant ABS material, which has good insulation performance and impact resistance; Built in overcurrent, overvoltage, and short-circuit protection circuits can effectively prevent damage to equipment caused by abnormal power supply; When the concentration of 13CO2 exceeds the alarm threshold set by the user, an alarm signal (optional relay output) will be promptly output to remind the staff to take corresponding measures.

Working principle

This detector is based on laser absorption spectroscopy technology (TDLAS, tunable diode laser absorption spectroscopy technology) to achieve precise monitoring of 13CO2. The core workflow is as follows:

1. Laser emission: The tunable diode laser inside the device emits a specific wavelength of laser, which is precisely tuned to match only the characteristic absorption spectral lines of 13CO2 molecules, and will not be absorbed by 12CO2 and other gas molecules.

2. Gas effect: When the laser passes through a monitoring area containing 13CO2 (air sample or gas inside the pipeline), some of the laser energy will be absorbed by 13CO2 molecules, and the degree of absorption is proportional to the concentration of 13CO2 (following Lambert Beer's law).

3. Signal reception and conversion: After the laser passes through the monitoring area, it is received by the photodetector on the other side, which converts the optical signal into a corresponding electrical signal and transmits it to the data processing unit.

4. Data processing: The data processing unit analyzes the electrical signal through a dedicated algorithm, calculates the concentration value of 13CO2 based on parameters such as laser wavelength and optical path length, and automatically compensates for errors caused by environmental factors such as temperature and humidity.

5. Signal output and display: The processed concentration data is output to external control systems (such as PLC and DCS systems) through 4-20mA analog signals or RS485 digital signals, and is displayed in real-time on the equipment's LCD screen for on-site personnel to view.

In addition, the built-in calibration module of the device will periodically (or according to user instructions) initiate the calibration process, correct the measurement deviation of the sensor by comparing it with the standard gas concentration, and ensure the accuracy of long-term monitoring.

Precautions

5.1 Installation precautions

-The installation location should avoid direct sunlight, direct rainwater erosion, and strong vibration environments. At the same time, it should be away from high-temperature heat sources (such as heaters, boilers, etc.) and strong electromagnetic interference sources (such as high-power motors, frequency converters, etc.), and the distance from such interference sources should not be less than 1 meter.

-When installing on a wall, a well ventilated location should be selected to ensure that the air can smoothly come into contact with the sensor; When installing in a pipeline, it is necessary to ensure that the sampling point is located in an area where the gas flow inside the pipeline is stable, to avoid measurement delays caused by dead volume or eddy currents.

-During the installation process, the electrical wiring diagram should be strictly followed to ensure that the power supply voltage is consistent with the rated voltage of the equipment, the positive and negative pole connections are correct, and to avoid equipment damage caused by reverse connections; After the wiring is completed, waterproof sealing treatment should be done (especially during outdoor installation).

-After the equipment installation is completed, it should be ensured that the shell is not damaged and the protection level is not affected.

5.2 Precautions for Operation and Use

-Before starting the equipment, check whether the power supply line is normal. After confirming that there are no errors, connect the power supply. After starting, wait for 5-10 minutes until the equipment completes preheating and self checking before setting or calibrating parameters.

-When performing manual calibration, it is necessary to use 13CO2 standard gas that has been certified by metrology. The concentration of the standard gas should be selected at around 80% of the range (such as 8%). During the calibration process, ensure that the standard gas is uniformly and stably introduced into the sensor chamber.

-Avoid frequent starting and stopping of equipment, as frequent starting and stopping may lead to unstable sensor performance and affect measurement accuracy.

-During the operation of the equipment, if abnormal display screens, unstable output signals, or alarms are found, the power supply and wiring should be checked for normal operation. If the problem is still not resolved, do not disassemble the equipment by yourself, and contact ABB professional after-sales personnel for repair.

5.3 Maintenance and Care Precautions

-Regularly clean the equipment casing by wiping it with a dry and soft cloth, avoiding the use of corrosive solvents such as alcohol and gasoline to prevent the casing from aging or being damaged.

-Regularly check whether the sensor air inlet is blocked by dust or debris. If there is any blockage, it should be gently blown clean with compressed air (pressure ≤ 0.1MPa) in a timely manner to ensure smooth gas circulation.

-It is recommended to calibrate the equipment every 6 months (which can be shortened to 3 months if used in harsh environments), and the calibration records should be properly kept for future traceability.

-When the equipment is not used for a long time, the power supply should be disconnected and placed in a dry, ventilated, and non corrosive gas environment to avoid long-term storage that may cause sensor performance degradation.

5.4 Safety Warning

-This device is only used for monitoring the concentration of 13CO2 gas and should not be used for detecting other gases to avoid measurement errors or equipment damage caused by inconsistent gas types.

-Equipment maintenance must be carried out by professional personnel authorized by ABB. Unauthorized disassembly or modification of equipment may result in equipment failure, measurement errors, and even safety risks, and may result in loss of product warranty.

-If there are high concentrations of corrosive gases (such as chlorine gas, hydrogen sulfide, etc.) in the monitoring environment, ABB technicians should be informed in advance to evaluate whether a dedicated gas pretreatment device is needed to avoid sensor corrosion.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-