This controller belongs to the ABB CM10 series basic process control unit, with "precise control, simplified operation, stable and reliable" as the design core. It is designed to meet the control needs of small and medium-sized production equipment, optimizing cost and installation convenience while ensuring core control functions. It adopts a modular structure design, supports flexible expansion, and can quickly adapt to the control requirements of different processes; Equipped with an intuitive operating interface and comprehensive fault diagnosis functions, reducing the threshold for operation and maintenance, even non professional technicians can quickly get started.

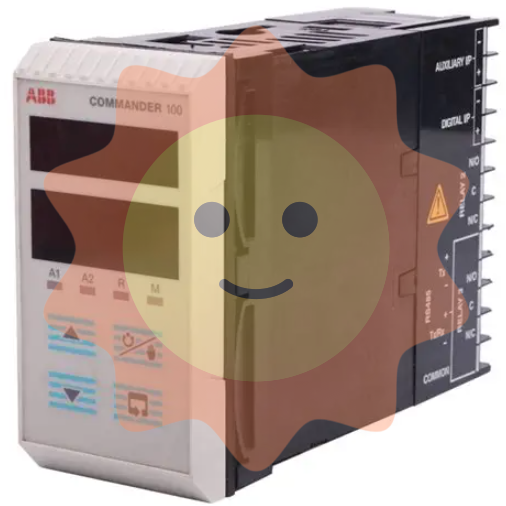

ABB CM10/00MU1E0/STD Process Controller

Core positioning and design philosophy of the product

This controller belongs to the ABB CM10 series basic process control unit, with "precise control, simplified operation, stable and reliable" as the design core. It is designed to meet the control needs of small and medium-sized production equipment, optimizing cost and installation convenience while ensuring core control functions. It adopts a modular structure design, supports flexible expansion, and can quickly adapt to the control requirements of different processes; Equipped with an intuitive operating interface and comprehensive fault diagnosis functions, reducing the threshold for operation and maintenance, even non professional technicians can quickly get started.

As a front-end control device in industrial automation control systems, CM10/00MU1E0/STD can independently complete single loop control and can also be connected to the upper computer system through communication interfaces to achieve centralized monitoring and data management, and build a complete data link from on-site control to cloud management.

Core technical parameters

model

CM10/00MU1E0/STD

control loop

Single loop control, supporting PID, PI, P and other control algorithms

input signal

Analog input: 4-20mA DC, 0-10V DC; Digital input: 2-channel dry contact input

output signal

Analog output: 1 channel 4-20mA DC (load ≤ 500 Ω); Relay output: 1 normally open/normally closed option

control accuracy

Input accuracy: ± 0.1% FS; Control accuracy: ± 0.2% FS

display mode

Dual row LED display, upstream displays measured values, downstream displays set/output values

working power supply

AC 220V ± 10%, 50/60Hz; power consumption ≤ 5W

working environment

Temperature: 0-50 ℃; Humidity: 10% -90% RH (no condensation); Non corrosive gas and dust environment

communication interface

RS485 interface, supports Modbus RTU protocol, can be connected to SCADA system

Installation method

Standard DIN rail installation (35mm), installation depth ≤ 100mm

Core functional advantages

1. High precision PID control ensures process stability

The controller is equipped with an optimized PID control algorithm and supports self-tuning function. It can automatically adjust the proportional (P), integral (I), and derivative (D) parameters according to the fluctuation of process parameters, quickly respond to parameter changes, and suppress overshoot. For example, in temperature control scenarios, when load fluctuations cause temperature deviation from the set value, the controller can start adjustment within 2-5 seconds to control the temperature deviation within ± 0.5 ℃, effectively avoiding product quality problems caused by parameter fluctuations.

2. Flexible signal adaptation capability

Compatible with multiple mainstream input and output signal types, it can be directly connected to various field instruments such as thermocouples, thermistors, pressure transmitters, flow sensors, etc., without the need for additional signal converters. The switching of input signal types and range calibration can be completed through panel buttons, adapting to the measurement requirements of different processes and reducing system integration complexity.

3. Comprehensive alarm and protection functions

Support multiple alarm modes such as high limit alarm, low limit alarm, deviation alarm, etc. When the process parameters exceed the set range, the controller will promptly prompt through LED indicator flashing, relay output triggering sound and light alarm, etc. At the same time, it can be linked to control the output to cut off related equipment, avoiding the expansion of dangerous working conditions. In addition, the device has power overvoltage protection and output short circuit protection functions, effectively improving the operational safety of itself and the system.

4. Convenient operation and data management

Adopting a simple operation interface of "button+LED display", setting value modification, parameter configuration, self-tuning startup and other operations can be completed through 4 function buttons, equipped with password protection function to prevent unauthorized personnel from misoperation. With the help of RS485 communication interface, measurement data, control output data, and alarm information can be uploaded in real time to the upper computer, achieving centralized recording and traceability of production data and providing data support for process optimization.

5. High reliability and long lifespan design

Internally, industrial grade core chips and high-quality electronic components are used, which have undergone strict high and low temperature aging, vibration and impact testing, with an average time between failures (MTBF) of over 100000 hours. The shell is made of flame-retardant ABS material, which has good anti-interference performance and can operate stably in complex electromagnetic environments in industrial sites, adapting to the needs of harsh working conditions such as chemical and metallurgical industries.

Applicable scenarios and typical applications

The CM10/00MU1E0/STD process controller, with its high cost-effectiveness and flexible adaptability, is widely used for parameter control in various small and medium-sized industrial production processes. Typical scenarios include:

1. Chemical industry: temperature control of reaction vessels, liquid level regulation of storage tanks, stable control of pipeline pressure. For example, in fine chemical synthesis processes, precise control of reaction temperature within ± 1 ℃ ensures that chemical reactions are complete and product purity meets standards.

2. Food and pharmaceutical industry: Temperature control of sterilization kettle, liquid level control of ingredient tank, stable control of liquid flow rate, in compliance with strict hygiene and process requirements for food and drug production, to avoid affecting product quality due to parameter fluctuations.

3. Energy industry: Small boiler water level control, thermal oil temperature regulation, gas pressure stability control, ensuring the safety and efficiency of energy production process, and reducing energy loss.

4. Building materials industry: Temperature control of concrete mixing tanks, viscosity auxiliary control during coating production process, to improve the stability and qualification rate of building materials products.

5. General industry: Independent control of single parameters such as temperature, pressure, and flow rate for various production lines, serving as the core control unit of small automation systems and simplifying system architecture.

Key points for installation and debugging

1. Installation specifications

-Choose an installation location with good ventilation, away from heat sources (such as steam pipes and heating equipment) and strong electromagnetic interference sources (such as frequency converters and high-power motors), and avoid direct sunlight.

-Adopting 35mm standard DIN rail installation, at least 5mm of heat dissipation space should be reserved between controllers and between controllers and other devices to prevent equipment failure caused by poor heat dissipation.

-When wiring, strictly follow the terminal diagram identification to ensure that the positive and negative terminals of the power supply, input signal, and output signal are connected correctly, and to avoid component burnout caused by reverse connection; Separate strong and weak electrical lines during wiring to reduce interference.

2. Debugging steps

1. Pre power on inspection: Confirm that the power supply voltage is consistent with the rated voltage of the controller, the wiring is secure and not loose, and the housing is not damaged.

2. Parameter configuration: After power on, enter the parameter setting interface and set the input signal type (such as 4-20mA corresponding to pressure transmitter) and range (such as 0-1MPa) according to the type of on-site instrument; Set the set value and alarm upper and lower limits according to the process requirements.

3. PID self-tuning: Switch the controller to automatic mode, activate the PID self-tuning function, and the controller will automatically calculate the optimal PID parameters through step testing. After self-tuning is completed, save the parameters and put them into operation.

4. Function verification: Simulate process parameter fluctuations (such as manually adjusting sensor signals), observe whether the output response of the controller is timely and accurate; Trigger the alarm condition and check if the alarm function is working properly.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-