The YOKOGAWA ALP121 communication module is an industrial grade PROFIBUS-DP communication interface component launched by Yokogawa Electric in Japan. Its core positioning is to provide a stable and efficient communication bridge between Yokogawa Distributed Control System (DCS) and on-site PROFIBUS-DP bus devices. Its core function is to achieve bidirectional data exchange between DCS system and on-site PROFIBUS-DP slave devices (such as sensors, actuators, intelligent instruments, etc.), complete the issuance of control instructions and upload on-site process data. This module supports the standard PROFIBUS-DP communication protocol and has modular design features, which can be flexibly integrated into various control system architectures in Yokogawa. It also has excellent anti-interference ability and stable operating performance, and is suitable for complex electromagnetic environments in industrial sites. It is widely used in industries such as petrochemicals, power, metallurgy, and manufacturing that require high reliability in industrial communication.

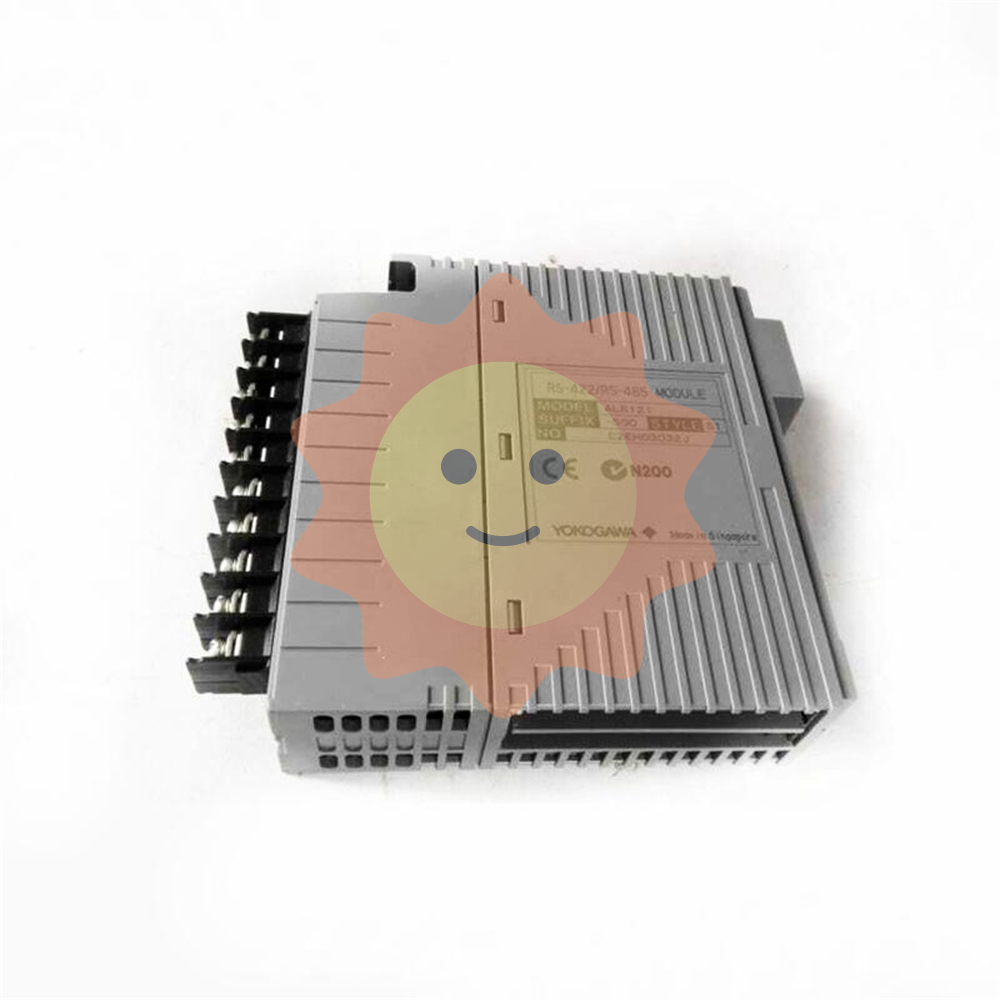

YOKOGAWA ALP121 Communication Module

Product Overview

The YOKOGAWA ALP121 communication module is an industrial grade PROFIBUS-DP communication interface component launched by Yokogawa Electric in Japan. Its core positioning is to provide a stable and efficient communication bridge between Yokogawa Distributed Control System (DCS) and on-site PROFIBUS-DP bus devices. Its core function is to achieve bidirectional data exchange between DCS system and on-site PROFIBUS-DP slave devices (such as sensors, actuators, intelligent instruments, etc.), complete the issuance of control instructions and upload on-site process data. This module supports the standard PROFIBUS-DP communication protocol and has modular design features, which can be flexibly integrated into various control system architectures in Yokogawa. It also has excellent anti-interference ability and stable operating performance, and is suitable for complex electromagnetic environments in industrial sites. It is widely used in industries such as petrochemicals, power, metallurgy, and manufacturing that require high reliability in industrial communication.

Specification parameters

The YOKOGAWA ALP121 communication module ensures the reliability and real-time performance of industrial bus communication with precise technical parameters. The core specification parameters have been verified at the industrial level, and the specific details are as follows:

-Basic information: The model is ALP121 (including sub models such as ALP121-S00 and ALP121-S01), the manufacturer is YOKOGAWA (Yokogawa Electric), the product type is PROFIBUS-DP communication module, and the country of origin is Japan; Model suffix description: - S represents standard type, followed by the number 00 for basic type, and 01 for G3 option type using ISA standard; The core adaptation system is Yokogawa's various distributed control systems (DCS);

-Communication protocol and speed: Supports PROFIBUS-DP standard communication protocol, compatible with PROFIBUS-DP V0/V1 protocol specifications; The communication rate can be flexibly configured, ranging from 9.6kbps to 12Mbps, and supports automatic rate matching and negotiation;

-Communication interface and topology: equipped with standard PROFIBUS-DP bus interface (DB9 or terminal type), supporting bus topology structure; Multiple PROFIBUS-DP slave devices can be connected, and the maximum number of slave devices complies with the PROFIBUS-DP protocol specifications; Support bus terminal resistor configuration to ensure bus signal integrity;

-Power parameters: Powered by a DC 24V standard industrial power supply, with a supply voltage range of DC 20.4V~26.4V and a typical power consumption of ≤ 5W; equipped with reverse power protection function to prevent module damage caused by reverse polarity of the power supply;

-Environmental adaptability parameters: working temperature range is 0 ℃~40 ℃, storage temperature range is -20 ℃~70 ℃; The relative humidity adaptation range is 25%~80% RH (without condensation); Has good electromagnetic compatibility performance and can resist electromagnetic interference generated by industrial field frequency converters, high-power motors, and other equipment;

-Physical and installation parameters: Adopting a compact modular design, the external dimensions are compatible with Yokogawa standard module installation specifications, weighing approximately 300g; the installation method is 35mm industrial standard DIN rail installation or module slot installation, suitable for dense layout requirements inside the control cabinet;

-Special functional parameters: Supports master/slave mode configuration (default is master adaptation mode); Capable of monitoring communication status and diagnosing faults; Support bus redundancy configuration (some models) to improve communication link reliability; Equipped with address configurable function, the module communication address can be set through software.

Performance characteristics

The YOKOGAWA ALP121 communication module integrates Yokogawa Electric's core technology in the field of industrial communication, with multiple performance advantages adapted to industrial PROFIBUS-DP bus scenarios, comprehensively ensuring the stability and reliability of communication links:

-Standard protocol compatibility and flexible adaptation: strictly following the PROFIBUS-DP V0/V1 standard protocol, it can seamlessly integrate with various slave devices on the market that comply with the PROFIBUS-DP standard, without the need for additional protocol conversion devices, and has strong universality; Support multi rate configuration, allowing for flexible selection of suitable rates based on on-site communication distance and environment;

-Stable communication and real-time response: High performance communication processing chips and optimized signal transmission circuits are used to ensure low data transmission delay and error rate, which can meet the real-time requirements of industrial control scenarios; Support the access of a large number of slave devices to ensure the stability of multi device collaborative communication;

-Strong anti-interference and adaptability to harsh environments: Adopting a fully metal shell shielding design and optimized circuit filtering technology, it can effectively block electromagnetic interference, ground loop interference and other problems in industrial sites, ensuring stable communication even in strong interference environments such as frequency converters and high-power motors;

-Convenient installation and maintenance: adopting modular structure and standard DIN rail installation design, it can be quickly integrated into the control unit of Yokogawa DCS system; Equipped with clear communication status indicator lights (power light, communication operation light, fault alarm light), which can intuitively feedback the working status of the module, making it easy for operation and maintenance personnel to quickly locate the fault point;

-Rich feature expansion: supports flexible configuration of master-slave mode, adapts to different communication topology requirements; Equipped with comprehensive fault diagnosis function, it can monitor the bus communication status in real time. When there are communication interruptions, rate mismatches, slave station faults and other problems, it can trigger alarms in a timely manner and feedback to the upper system; Some models support redundant configuration, further improving the availability of communication links;

-Industrial grade reliable operation: Using industrial grade electronic components and rigorous production processes, it has a wide temperature working range and good environmental adaptability. It can operate continuously and stably in industrial environments with high dust and humidity fluctuations, and has excellent mean time between failures (MTBF) performance.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-