-Product traceability and positioning: Originating from Japan, it belongs to the supporting terminal equipment of Yokogawa CENTUM DCS system, focusing on solving the efficient docking problem of multiple types of signals and control system core units on site. Its lifecycle status is active, and it can provide long-term stable supply and technical support.

-Physical specifications: Adopting a compact design, the dimensions are precisely controlled to be 100mm x 120mm x 25mm (length x width x height), with a weight of only about 0.3kg. The lightweight structural design greatly reduces installation loads and facilitates dense layout inside the control cabinet.

-Environmental adaptability: The working temperature range is from 0 ° C to 55 ° C, which can adapt to the normal temperature working environment of most industrial plants; At the same time, it has good anti-interference ability and can work stably in complex electromagnetic environments in industrial sites. The storage temperature range is -20 ° C to 65 ° C, meeting the storage and transportation needs of different regions.

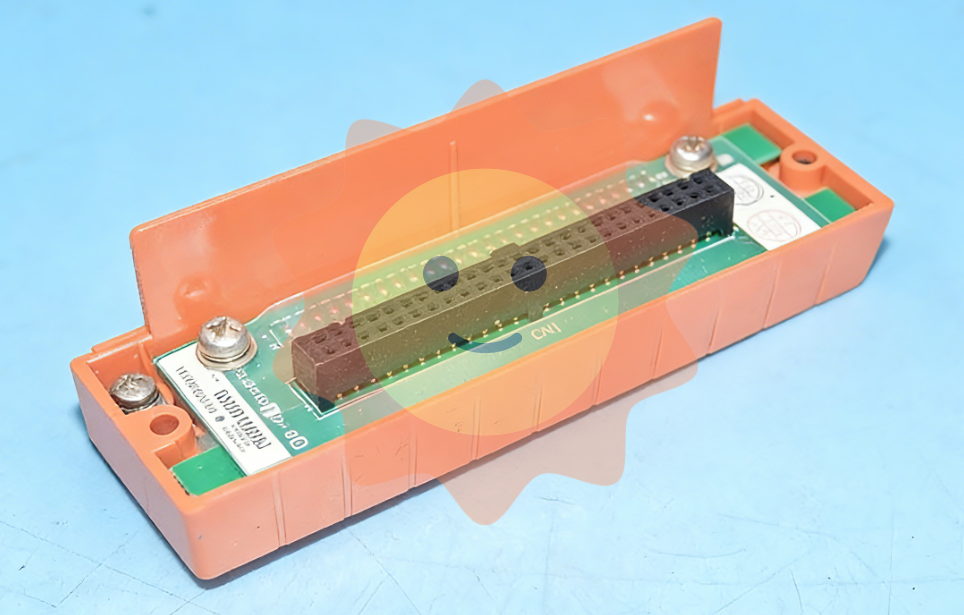

YOKOGAWA S9361DH-00 Terminal Board Module

Core Basic Information

-Product traceability and positioning: Originating from Japan, it belongs to the supporting terminal equipment of Yokogawa CENTUM DCS system, focusing on solving the efficient docking problem of multiple types of signals and control system core units on site. Its lifecycle status is active, and it can provide long-term stable supply and technical support.

-Physical specifications: Adopting a compact design, the dimensions are precisely controlled to be 100mm x 120mm x 25mm (length x width x height), with a weight of only about 0.3kg. The lightweight structural design greatly reduces installation loads and facilitates dense layout inside the control cabinet.

-Environmental adaptability: The working temperature range is from 0 ° C to 55 ° C, which can adapt to the normal temperature working environment of most industrial plants; At the same time, it has good anti-interference ability and can work stably in complex electromagnetic environments in industrial sites. The storage temperature range is -20 ° C to 65 ° C, meeting the storage and transportation needs of different regions.

-Certification standard: Through EU CE certification, it strictly complies with international industrial safety and electromagnetic compatibility standards, ensuring legal and compliant use in industrial scenarios in the EU and most parts of the world, and guaranteeing the safety and reliability of equipment operation from the design source.

-Power supply specifications: Suitable for industrial standard 24V DC power supply, with a tolerance of ± 10% for power supply voltage fluctuations, and stable power supply adaptability. It can be directly connected to common DC power supply systems in industrial sites without the need for additional dedicated power modules.

Core functions and technical features

The core advantage of the S9361DH-00 terminal board module lies in its powerful signal processing capability and flexible system adaptability. The specific functional characteristics can be divided into the following key dimensions:

1. Multi channel signal compatibility capability

The module integrates rich channel resources and can simultaneously process both analog and digital core industrial signals, with a total of 32 channels (16 analog input/output channels+16 digital I/O channels), achieving centralized control of multiple types of field devices by a single module:

-Analog signal channel: 16 analog input/output channels support flexible configuration and can adapt to commonly used industrial 0~10V voltage signals and 4~20mA current signals. It can directly interface with analog output devices such as temperature sensors, pressure transmitters, liquid level sensors, as well as analog input devices such as actuators and regulating valves. The channel accuracy is up to ± 0.1% of full scale, with a resolution of 16 bits, which can accurately capture subtle changes in on-site signals and ensure the precise execution of control instructions.

-Digital signal channel: The 16 channel digital I/O channel adopts 24V DC standard, which can collect the status of on-site switches (such as limit switches, emergency stop buttons) and control the switching of actuating components (such as relays, solenoid valves). The digital channel has photoelectric isolation protection function, which can effectively prevent damage to the core control system caused by on-site voltage fluctuations or surges.

2. High speed signal processing and transmission

In response to the strict requirements for real-time performance in industrial process control, S9361DH-00 adopts a high-performance signal processing chip, with a data acquisition rate and output update rate of 1000 samples/second (1000 times/second). This high-speed processing capability ensures real-time response of the core control loop, which can quickly feedback changes in on-site equipment status and execute control instructions, effectively avoiding control deviations caused by signal delays, especially suitable for industrial scenarios that require precise timing control.

3. High reliability and fault-tolerant design

The module adopts a fault-tolerant design, equipped with dual redundant power interfaces and dual redundant communication ports, which can achieve redundant backup of power and communication. When the main power supply or main communication link fails, the system can automatically switch to the backup link, ensuring uninterrupted signal transmission and greatly improving the overall stability of the control system. At the same time, high-quality electronic components are used inside the module, which have overvoltage and overcurrent protection functions, effectively resisting damage to the module caused by abnormal power supply on site.

4. Flexible installation and integration methods

Supports two installation methods: panel installation and rack installation, and can flexibly choose the installation form according to the layout requirements of the control cabinet. The module adopts a standardized terminal design for easy wiring operation, and the terminals have anti loosening and anti oxidation treatment, which can effectively reduce the risk of contact failure during long-term operation. In addition, the module supports Modbus TCP/IP communication protocol, making it easy to integrate into existing industrial Ethernet control systems and achieve rapid integration with devices such as upper computers and PLCs.

Typical application areas

With its core advantages of multi-channel, high precision, and high reliability, the S9361DH-00 terminal board module is widely used in various industrial automation scenarios, becoming a key bridge connecting field devices and control systems. Typical application areas include:

1. Process control system

In process industries such as petrochemicals, fine chemicals, and pharmaceuticals, modules can centrally collect analog signals such as temperature, pressure, and liquid level of reaction vessels, and receive control system instructions to control the operating status of actuators such as feed valves, mixing motors, and exhaust valves through digital channels. Its high-speed signal processing capability can ensure precise control of chemical reaction processes, avoiding product quality issues or safety hazards caused by parameter fluctuations.

2. Manufacturing automation

In discrete manufacturing fields such as automobile manufacturing, electronic processing, and mechanical processing, modules can be integrated with various sensors (such as photoelectric switches and proximity switches) and actuators (such as cylinders and servo drives) on the production line to achieve automated control of the production process. For example, on the assembly line of automotive parts, the working status signals of each workstation can be collected through modules, and the start stop of the conveyor line and the action of the robotic arm can be synchronously controlled to improve production efficiency and process stability.

3. In the field of energy and environmental protection

In energy and environmental protection scenarios such as thermal power generation, hydropower generation, and sewage treatment, modules can be used to collect operating parameters of power generation units (such as speed, vibration, oil temperature), water quality parameters of water treatment processes (such as pH value, turbidity, dissolved oxygen), and control the operation of key equipment such as water pumps, fans, and aeration devices. Its high reliability design can meet the 24-hour continuous operation requirements in the field of energy and environmental protection, ensuring the stability and safety of the production process.

4. Building automation

In the building automation system of large commercial buildings and industrial plants, modules can be connected to temperature and humidity sensors of air conditioning systems, fan status sensors of ventilation systems, and switch components of lighting systems to achieve precise control and energy optimization of environmental parameters inside the building. By centralizing signal processing and control, building energy consumption can be reduced and environmental comfort can be improved.

Installation and operation precautions

To ensure the stable operation of the module and the safety of operators, the following specifications must be strictly followed during installation, wiring, and maintenance:

1. Installation environment requirements

The installation location should be selected in a dry, clean, non corrosive gas, and non strongly vibrating area, avoiding direct sunlight and rainwater erosion; At the same time, sufficient heat dissipation space should be reserved to ensure smooth module heat dissipation and prevent performance degradation or damage caused by high temperatures. When installing in the control cabinet, it should be kept away from high-power inductive loads (such as contactors and frequency converters) to reduce electromagnetic interference.

2. Safety wiring specifications

Before wiring, all relevant power sources must be cut off and warning signs reading 'No Switching on, Working' must be hung to avoid the risk of electric shock; When wiring, it is necessary to strictly follow the module wiring diagram, distinguish between analog signals, digital signals, and power lines, and avoid module damage caused by misconnection. It is recommended to use shielded cables with a specification of 15-22AWG. Analog signal cables and power cables should be wired separately, and the shielding layer should be grounded at one end to reduce signal interference. When tightening the wiring terminals, it is necessary to operate according to the prescribed torque to ensure a secure connection and prevent loose wiring caused by vibration.

3. Key points of maintenance and upkeep

Regular cleaning of dust on the surface of modules and wiring terminals is required for daily maintenance. Dry soft cloth or brush can be used for wiping, and the use of water or corrosive cleaning agents is strictly prohibited; Regularly check the fastening status of the wiring terminals and whether the cable insulation layer is damaged, and promptly deal with any problems found. The channel accuracy of the module needs to be calibrated every six months to ensure the accuracy of signal acquisition and output; Perform annual switching tests on the redundant power supply and communication links of the module to verify that the fault tolerance function is normal. If a module needs to be replaced during maintenance, it is necessary to ensure that the new module model is consistent with the original module. After replacement, channel calibration and system debugging need to be carried out again.

4. Fault Handling Standards

When a module experiences a fault alarm or abnormal signal, the first step is to cut off the power supply and check if the power supply voltage and wiring status are normal; If there is no problem with the wiring, the module can be swapped with the backup module through replacement method to determine whether it is a fault of the module itself. When it comes to repairing the internal circuit of the module, non professionals are strictly prohibited from disassembling it without authorization. They should contact the official after-sales or certified engineer of Yokogawa Electric for handling. After the fault handling is completed, the system needs to be re debugged to ensure that signal transmission and control functions are restored to normal.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-