The YOKOGAWA VI702 Vnet/IP interface card is a high-performance communication interface module designed by Yokogawa Electric for industrial automation distributed control systems (DCS) in Japan. Its core positioning is to serve as a data transmission bridge between the upper control station and the field control station (FCS), enabling real-time and reliable information exchange between the two. This interface card is specifically designed for mainstream DCS systems in Yokogawa, such as CENTUM VP, CS3000, CS1000, and is compatible with ProSafe-RS safety instrumented systems. It is widely used in complex industrial control reliability requirements such as petroleum, chemical, power, steel, and water treatment.

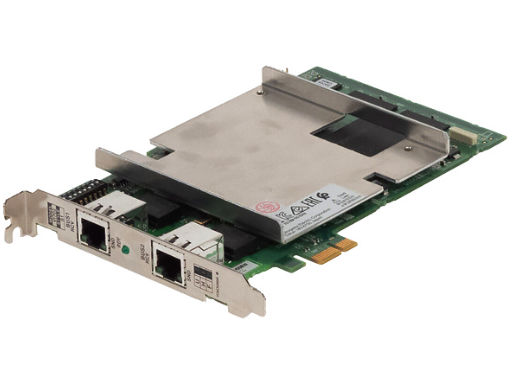

YOKOGAWA VI702 Vnet/IP Interface Card

Product Overview

The YOKOGAWA VI702 Vnet/IP interface card is a high-performance communication interface module designed by Yokogawa Electric for industrial automation distributed control systems (DCS) in Japan. Its core positioning is to serve as a data transmission bridge between the upper control station and the field control station (FCS), enabling real-time and reliable information exchange between the two. This interface card is specifically designed for mainstream DCS systems in Yokogawa, such as CENTUM VP, CS3000, CS1000, and is compatible with ProSafe-RS safety instrumented systems. It is widely used in complex industrial control reliability requirements such as petroleum, chemical, power, steel, and water treatment.

VI702 is an upgraded replacement model of Yokogawa's classic Vnet/IP interface card VI701. The core improvement lies in the iteration of the bus interface - upgrading from the previous generation PCI interface to PCI-E interface, in order to solve the compatibility problem between traditional PCI interface cards and new motherboards after the gradual elimination of old industrial computer motherboards. At the same time, it retains full compatibility with the original system, ensuring that users do not need to reconstruct the communication architecture during the system upgrade process, reducing upgrade costs and downtime risks.

Core technical parameters and hardware characteristics

2.1 Basic specifications

-Product positioning: Vnet/IP protocol specific communication interface card, realizing protocol conversion and data forwarding between PCI-E bus and Vnet/IP control network.

-Origin and Compliance: Originating from Japan, it meets multiple international electromagnetic compatibility (EMC) standards, including CE certification, C-tick certification, and KC certification, and can meet industrial installation specifications in different regions around the world.

-Physical parameters: Adopting a full height half length design, the external dimensions are 111.15mm × 167.65mm, with a weight of approximately 0.18kg, in compliance with the standard PCI-E card installation specifications, and suitable for the expansion slot space of most industrial control computers.

2.2 Communication Performance

-Communication Protocol: Native support for Vnet/IP real-time industrial Ethernet protocol, designed specifically for industrial control scenarios, with low latency and high certainty, ensuring real-time transmission of control commands and monitoring data.

-Transmission rate: Supports 1Gbps full duplex transmission, adopts 1000Base-T transmission standard, and has a data throughput far exceeding traditional industrial communication interfaces, which can meet the concurrent communication needs of large-scale DCS systems with multiple nodes.

-Connection specifications: Connected to network equipment through RJ45 interface, it needs to be used with Cat5e unshielded twisted pair (UTP). The maximum transmission distance between VI702 and layer 2 switch can reach 100 meters, which is suitable for the wiring needs of industrial sites.

2.3 Power and hardware indicators

-Power requirements: Equipped with 3.3V DC power supply, the allowable voltage fluctuation range is ± 9%, the maximum current consumption is 2.5A, the power consumption control is reasonable, and it can adapt to the power output capability of industrial control computers.

-Status indicator lights: The front of the card is equipped with three function indicator lights for intuitive feedback on the operating status:

-RDY light: Ready indicator light, which lights up when the card completes self check and the status is normal;

-RCV light: Receive indicator light, which lights up when an input signal is detected on the control bus;

-SND light: Send indicator light that lights up when an output signal is sent to the control bus.

2.4 PCI-E bus compatibility

Strictly following the PCI Express CEM Specification 1.0a x1 standard, supporting a signal transmission rate of 2.5GT/s. Although designed with x1 channel, it is compatible for installation in PCI-E slots with x1 to x16 specifications, providing high installation flexibility; It should be noted that this card is not compatible with traditional PCI slots and cannot be directly installed on old PCI interface industrial computers.

Core differences and compatibility with the previous generation product VI701

3.1 Core Differences

comparative dimension

VI702 (new model)

VI701 (old model)

Bus interface

PCI-E (x1 channel, compatible with x1-x16 slots)

PCI interface

interface dimensions

Shorter, compliant with PCI-E interface specifications

Longer, compliant with PCI interface specifications

Adapt to motherboard

PCI-E interface industrial computer motherboards produced after 2001

PCI interface industrial computer motherboards produced before 2001

3.2 Full compatibility guarantee

To reduce the cost of system upgrades for users, Yokogawa ensured comprehensive compatibility with VI701 when designing VI702, which is reflected in three dimensions:

-Driver compatibility: Both drivers are completely identical and integrated into the COMDRV folder of DCS system installation disks such as CS3000. There is no need to develop or install new drivers separately for VI702;

-Network compatibility: The Vnet/IP interface of VI702 can coexist directly with VI701 on the same control bus, without the need to adjust network topology or protocol parameters;

-Configuration compatibility: The domain number and station number configuration method of VI702 is exactly the same as that of VI701, and users can use their original configuration habits and operating procedures.

Installation and configuration process

4.1 Preparation before installation

-Hardware inspection: Confirm that the appearance of the VI702 card is undamaged, the interface pins are not bent or oxidized, and the status indicator light is intact; Prepare matching Cat5e Category 5e Ethernet cables, RJ45 crystal heads, and crimping tools;

-Software preparation: Obtain the installation CD for the corresponding DCS system (such as CS3000), locate it in the COMDRV folder, and confirm that it contains UNINSTAL.BAT (uninstallation script) and SETUP.BAT (installation script);

-Equipment power-off: Turn off the power supply of the industrial control computer and the corresponding distribution unit, unplug the power plug, and avoid damage to the card or motherboard caused by live operation.

4.2 Driver uninstallation (VI701 replacement scenario)

If you want to replace the old VI701 card, you need to first uninstall the old card driver. The steps are as follows:

1. Start the industrial computer and enter the Windows operating system (commonly used Windows Server series in Yokogawa DCS);

2. Open "My Computer" and navigate to the COMDRV folder on the CS3000 installation disk;

3. Double click to run the UNINSTAL.BAT batch file and follow the pop-up prompt to complete the driver uninstallation;

After uninstallation is complete, restart the industrial computer to ensure that the old drivers are completely cleared (you can check whether there are still VI701 related device residues through the "Device Manager").

4.3 Hardware Installation

1. Open the industrial computer chassis, find an available PCI-E slot (x1 to x16 are all acceptable), and remove the corresponding baffle of the slot;

2. Hold the edge of the VI702 card and align it with the PCI-E slot. Insert it smoothly and ensure that the gold finger of the card fully contacts the slot. Secure the card cover with screws and close the chassis;

3. Use the prepared Cat5e Ethernet cable to connect the RJ45 interface of VI702 to the layer 2 switch of the field control bus, ensuring that the Ethernet cable is firmly connected and the crystal head is not loose;

4. Connect the power supply and distribution unit of the industrial computer, and prepare for driver installation and network configuration.

4.4 Driver Installation and Network Configuration

After restarting the industrial computer, the system will automatically detect new hardware (VI702) and pop up a hardware installation wizard;

2. Select 'Manual driver installation', navigate to the COMDRV folder, double-click to run SETUP.BAT, and follow the wizard prompts to complete the driver installation;

3. After the driver installation is completed, restart the industrial computer again and confirm through the "Device Manager" that the VI702 device is in normal condition without any yellow exclamation marks;

4. Open the DCS system configuration software and set the IP address, subnet mask, gateway, domain number, and station number of VI702 according to the original configuration parameters of VI701;

5. After the configuration is completed, start the Vnet/IP network service and observe whether the RDY light of VI702 is on. If the RDY light is always on and the RCV/SND light flashes with data transmission, it indicates that the installation and configuration are successful.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-