Siemens 7XV5653-0BA00 dual channel binary signal transmitter

DIP switch (S1, S2) function:

S1 (2-position DIP switch):

|Switch | Position | Meaning|

|1 | Open circuit (off) | The light goes out when the fiber optic receiver is idle|

|1 | Closed (on) | The light is on when the fiber optic receiver is idle|

|2 | Open circuit (off) | The light goes out when the fiber optic transmission is idle|

|2 | Close (on) | The light is on when the fiber optic transmission is idle|

S2 (8-bit DIP switch): By combining different DIP switches (DIP1-DIP8), multiple functional settings can be achieved, including baud rate (1200-112200 baud), data format (8E1: 8-bit data, even parity, 1-bit stop bit); 8N1: 8-bit data, no checksum, 1-bit stop bit), MA function (block MA, enable MA), test mode (test mode on, test mode off), working mode (only transmit, send/receive), boot loader (boot loader on, boot loader off), specific combinations are shown in Table 7, bold indicates factory settings.

Special mode explanation:

Test mode enabled: The binary signal transmitter performs self-test. If the binary input is activated (voltage applied), the binary LED (BI-1 or BI-2) lights up, and the corresponding relay (K1 or K2) and associated LED (K1 or K2) are activated; The memory test diagnosis and DIP switch position will be output to the serial interface (RS232), which can be displayed through the terminal program running on the PC.

Test mode off: The binary signal transmitter is ready to operate normally.

Blocking MA: Blocking message output, not controlling relay.

Enable MA: Normal operation, message output is not blocked.

Only transmitting: Binary signal transmitters only function as transmitters and do not report missing incoming signals as communication errors.

Baud rate setting: query the baud rate once after power on (DIP switch position); In the activated test mode, the baud rate will be continuously queried and reset; Set baud rate during operation: Set the baud rate through DIP switch 0-2 and briefly switch the on/off state of DIP switch 6 (test mode).

(4) Adjustment of picking threshold for binary input

To adjust the threshold of binary input, the binary signal transmitter needs to be turned on and the jumper changed. When the device is turned on, it is prohibited to run and the power supply needs to be disconnected first.

Steps for adjusting jumper position: Disconnect the power supply of the device → Remove the housing cover (carefully push the buckle of the cover towards the inside of the device with a small screwdriver) → Change the jumper position according to Table 8 → Clip the cover back to its original position.

Corresponding relationship between jumper position and picking threshold:

|Jumper | Position | Pick threshold | Binary input|

|X100|1-2|17V|1(BI-1)|

|X100|2-3|70V|1(BI-1)|

|X200|1-2|17V|2(BI-2)|

|X200|2-3|70V|2(BI-2)|

(5) Dimensional drawing

The equipment has specific size specifications, as shown on page 32 of the document, including the size parameters of components such as clips and terminals (such as 95mm, 105mm, 90mm, etc.).

Order data

Name, Model, Specification

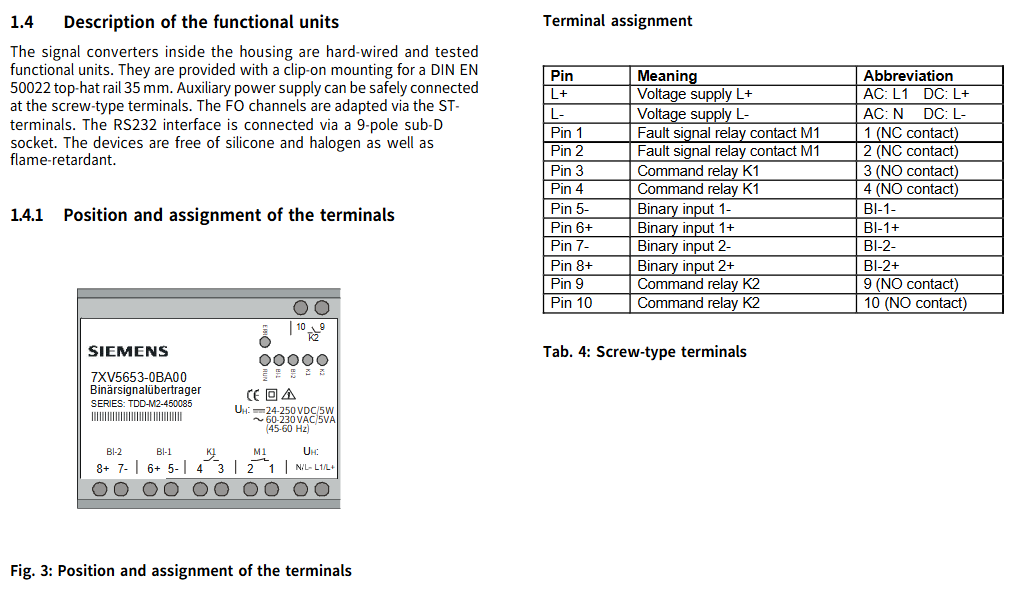

Dual channel binary signal transmitter 7XV5653-0BA00 with 2 binary inputs, 2 command inputs, and 1 fault signal output (via terminals)

Installation and Debugging

(1) Installation precautions and steps

Installation warning: Some components of electrical equipment carry dangerous voltage during operation. Ignoring the operating instructions may result in serious personal injury or property damage. The installation and electrical connection of the equipment are only allowed to be carried out by qualified personnel, and all warnings must be strictly followed; Do not directly stare at the fiber optic transmission diode while wearing optical assistive devices; Prohibit operation when the device is turned on.

Installation requirements:

The installation location should be free of vibration and comply with the allowed ambient temperature (working or functional temperature, see technical parameters). Ignoring the temperature range required for normal function may lead to equipment failure and signal converter failure.

The equipment has a plastic casing and belongs to overvoltage category III according to DIN EN 61010 Part 1.

The signal transmitter can be installed on a 35mm top cap guide rail (according to DIN EN 50022) with a snap fit.

The equipment is only allowed to operate within a closed enclosure or cabinet, and the installation location is only accessible to qualified personnel.

Installation steps: Clip the binary signal transmitter onto the top cap guide rail using a snap on mounting component.

(2) Connection requirements and steps

Connection specifications: Electrical connections must comply with the installation regulations for high current devices, as well as VDE0100 and VDE0160 standards.

Power connection: The auxiliary power supply of the equipment needs to be equipped with an external isolation switch (for power safety isolation) and a safety device (fuse, 2AT or 4AT). The external isolation switch should be labeled accordingly, and the safety circuit breaker can simultaneously perform both functions.

Cable requirements:

Cable cross-section (single core cable or multi stranded wire): 0.5mm ² -2.5mm ².

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc