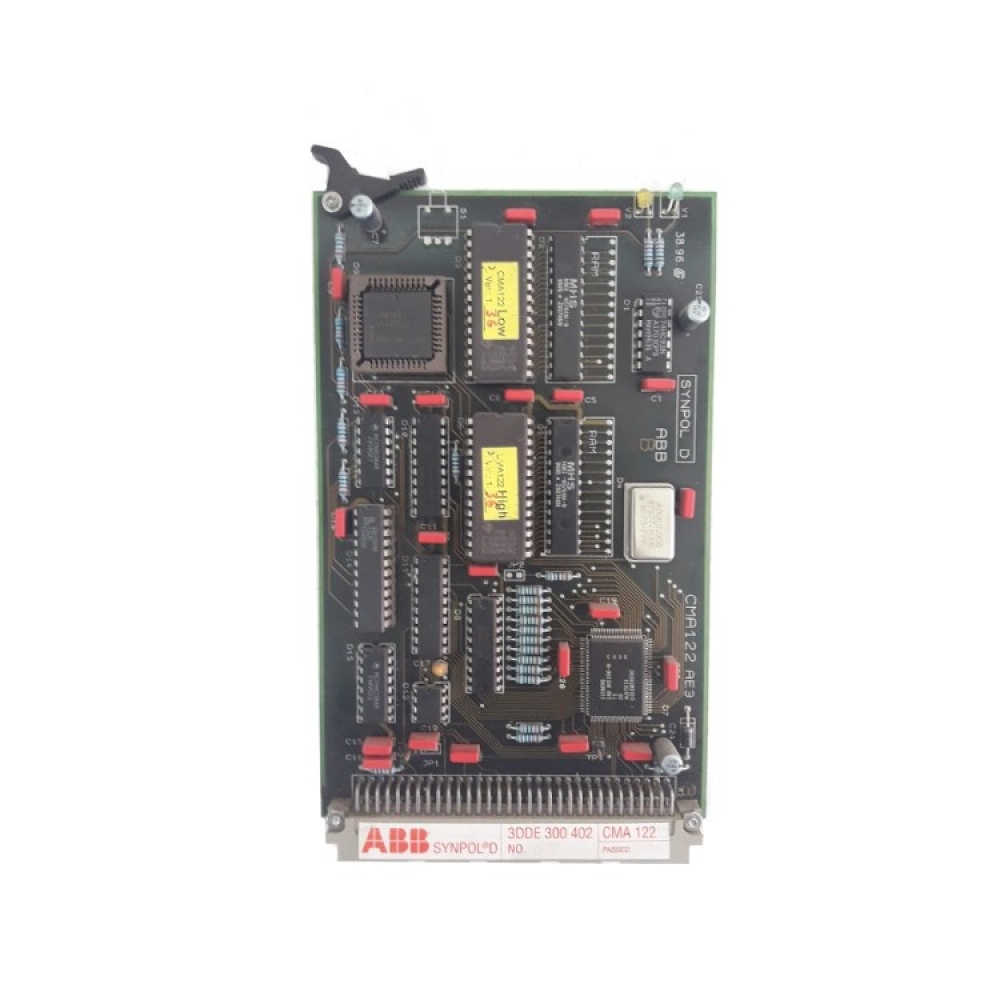

ABB DCP02 CPU MODULE

ABB DCP02 CPU MODULE

Product Overview

ABB DCP02 CPU module is the core brain of industrial automation control system, which is responsible for processing all kinds of data, executing control procedures and coordinating the operation of various components in the system. It plays a key role in the field of industrial automation by virtue of its powerful data processing capability and stable and reliable performance, and can be widely used in electric power, chemical industry, manufacturing industry and other industries, to meet the needs of automation control of different complexity, and provide strong support for the efficient and stable operation of industrial production.

Core Functions

1. Efficient data processing: equipped with a high-performance processor, it has strong computing power, which can quickly process a large amount of input and output data, and execute complex control algorithms and logic programmes. In large-scale industrial production lines, facing the real-time data collected by many sensors and various control instructions, DCP02 CPU module can quickly complete the analysis, arithmetic and processing of the data to ensure timely response of the system and guarantee the smooth operation of the production process.

2. Rich communication interfaces: Equipped with a variety of communication interfaces, such as Ethernet interface, RS-485, RS-232, etc., supporting a variety of communication protocols, including Modbus, PROFINET, TCP/IP, etc. This makes the module can be conveniently connected with other modules. This enables the module to conveniently exchange data and communicate with PLCs, HMIs (human-machine interfaces), sensors, actuators, and other control systems to achieve system integration and cooperative work. For example, connecting to a factory's management system through an Ethernet interface allows real-time uploading of production data for monitoring and decision-making by management personnel.

3. Flexible Programming and Configuration: It supports a variety of programming languages, such as ladder diagram, structured text, function block diagram, etc., which makes it convenient for engineers with different technical backgrounds to write programmes and configure the system according to project requirements. Meanwhile, users can flexibly set the parameters of the CPU module according to the actual application scenarios, such as input/output address assignment, communication parameter configuration, etc., in order to meet diversified control requirements.

4. High reliability and stability: Adopting redundancy design concept and supporting hot standby function, when the main CPU module fails, the standby module can be switched quickly and seamlessly to continue to perform the control tasks, which greatly reduces the risk of system downtime. In addition, the module has a perfect self-diagnostic function, which can monitor its own working status in real time, and once a fault is detected, it will immediately send out an alarm signal and take corresponding protective measures to ensure the safe and stable operation of the system. In harsh industrial environments, such as high temperature, high humidity, and strong electromagnetic interference, the DCP02 CPU module can also maintain stable operation with its excellent anti-interference performance and reliable hardware design.

Technical Specifications

Model:DCP02

Processor type: High-performance industrial-grade processor

Data processing speed: can quickly process a large amount of data, the specific speed varies depending on the application scenario.

Memory capacity: sufficient programme storage and data processing memory to meet the needs of complex control programmes.

Communication interface: Ethernet, RS-485, RS-232, etc.

Support communication protocols: Modbus, PROFINET, TCP/IP, etc.

Programming language: ladder diagram, structured text, function block diagram, etc.

Operating temperature range: -20℃ to + 60℃.

Humidity range: 5% to 95% (non-condensing)

Protection class:IP20

Precautions for use

Installation process

Power supply adaptation: Be sure to strictly use the specified power supply voltage, voltage fluctuations beyond the standard may lead to module performance degradation or even damage. Before connecting to the power supply, use professional equipment to test the stability of the power supply and the voltage value, and at the same time ensure that the power supply polarity is correctly connected to avoid burning the internal components of the module due to connection instead.

Static electricity protection: When operating the CPU module, the static electricity generated by the human body may cause irreversible damage to it. Therefore, operators should wear anti-static bracelets and ensure that the working environment is well grounded. During installation, avoid touching the circuit boards and pins of the module directly with your hands, and use anti-static tools for operation as much as possible.

Heat dissipation: Although the module's operating temperature range is from -20℃ to +60℃, it should be installed in a well-ventilated control cabinet to ensure its long-term stable operation. Avoid stacking debris around the module, maintain a safe distance from other heat generating equipment, and install a cooling fan if necessary to prevent the module from degrading or failing due to high temperature.

Use and maintenance

Procedure backup: Before updating the procedure or modifying the parameters of the module, the original procedure and configuration file must be completely backed up. Once the operation error leads to program loss or system crash, it can be quickly restored to the normal state, reducing downtime and potential losses.

Troubleshooting: When the module has a fault alarm, do not disassemble it immediately. Firstly, through the diagnostic function and the status indicator to determine the initial type of fault, check the communication connection, power supply and other external factors. If you are unable to determine the cause of the fault, you should contact ABB's professional technicians to avoid expanding the scope of the fault due to improper operation.

Regular maintenance: Clean the module regularly, use a dry, soft brush or compressed air to remove surface dust to prevent dust accumulation from affecting heat dissipation and electrical performance. At the same time, check whether the fixing screws of the module are loose, whether the communication cable and power cable are firmly connected, to ensure that the module is always in good working condition.

Related Models

DCP01 CPU Module

DCP03 CPU Module

DCP10 CPU Module

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor