Welcome to the Industrial Automation website!

Product

Article

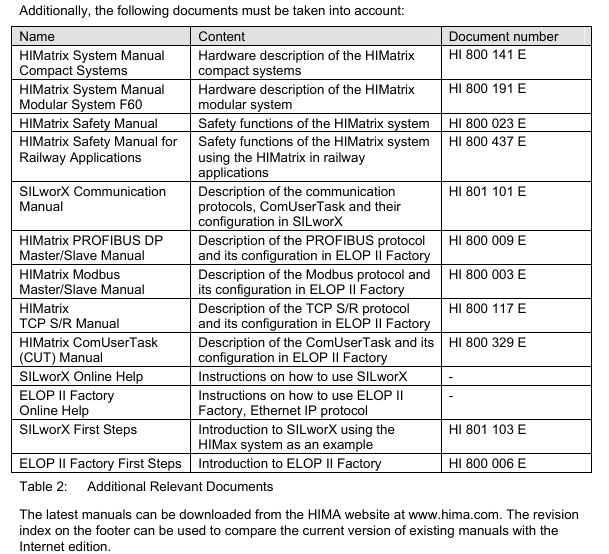

NameDescriptionContent

HIMatrix F30 01 Safety-Related Controller

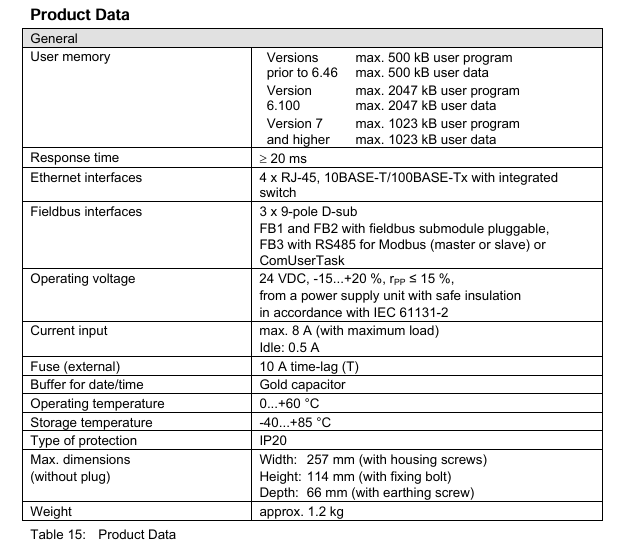

The safety-related F30 controller is a compact system in a metal housing with 20 digital inputs and 8 digital outputs.

The controller is available in various model variants for SILworX and ELOP II Factory.

The device is suitable for mounting in Ex-zone 2.

The device is TÜV-certified for safety-related applications up to SIL 3 (IEC 61508, IEC 61511 and IEC 62061), Cat. 4 and PL e (EN ISO 13849-1) and SIL 4 (EN 50126, EN 50128 and EN 50129).

Further safety standards, application standards and test standards are specified in the certificates available on the HIMA website.

The controller is available in various model variants for SILworX and ELOP II Factory.

The device is suitable for mounting in Ex-zone 2.

The device is TÜV-certified for safety-related applications up to SIL 3 (IEC 61508, IEC 61511 and IEC 62061), Cat. 4 and PL e (EN ISO 13849-1) and SIL 4 (EN 50126, EN 50128 and EN 50129).

Further safety standards, application standards and test standards are specified in the certificates available on the HIMA website.

HIMatrix F30 01 Safety-Related Controller

Product Description

The safety-related F30 controller is a compact system in a metal housing with 20 digital inputs and 8 digital outputs.

The controller is available in various model variants for SILworX and ELOP II Factory.

The device is suitable for mounting in Ex-zone 2.

The device is TÜV-certified for safety-related applications up to SIL 3 (IEC 61508, IEC 61511 and IEC 62061), Cat. 4 and PL e (EN ISO 13849-1) and SIL 4 (EN 50126, EN 50128 and EN 50129).

Further safety standards, application standards and test standards are specified in the certificates available on the HIMA website.

Safety Function

The controller is equipped with safety-related digital inputs and outputs.

Safety-Related Digital Inputs

The controller is equipped with 20 digital inputs. The state (HIGH, LOW) of each input is signaled by an individual LED.

Mechanical contacts without own power supply or signal power source can be connected to the inputs.

Potential-free mechanical contacts without own power supply are fed via an internal short circuit-proof 24 V power source (LS+). Each of them supply a group of 4 mechanical contacts.

With signal voltage sources, the corresponding ground must be connected to the input (L-)

For the external wiring and the connection of sensors, apply the de-energized-to-trip principle.

Thus, if a fault occurs, the input signals adopt a de-energized, safe state (low level).

If an external wire is not monitored, an open-circuit is considered as safe low level.

Reaction in the Event of a Fault

If the device detects a fault on a digital input, the user program processes a low level in accordance with the de-energized to trip principle.

The device activates the FAULT LED.

In addition to the channel signal value, the user program must also consider the corresponding error code.

The error code allows the user to configure additional fault reactions in the user program.

Line Control

Line control is used to detect short-circuits or open-circuits and can be configured for the F30 system, e.g., on EMERGENCY STOP inputs complying with Cat. 4 and PL e in accordance with EN ISO 13849-1.

To this end, connect the digital outputs DO 1 through DO 8 of the system to the digital inputs DI of the same system as follows:

The controller pulses the digital outputs to detect short-circuits and open-circuits on the lines connected to the digital inputs.

To do so, configure the Value [BOOL] -> system variable in SILworX or the DO[0x].Value system signal in ELOP II Factory.

The variables for the pulsed outputs must begin with channel 1 and reside in direct sequence, one after the other.

If the following faults occur, the FAULT LED located on the front plate of the controller blinks,the inputs are set to low level and an (evaluable) error code is created:

Cross-circuit between two parallel wires.

Invalid connections of two lines (e.g., DO 2 to DI 3),

Earth fault on one wire (with earthed ground only).

Open-circuit or open contacts, i.e., including when one of the two EMERGENCY STOP

switches mentioned above has been engaged, the FAULT LED blinks and the error code is created.

Equipment, Scope of Delivery

The following table specifies the available controller variants:

F30 01:Controller (20 digital inputs, 8 digital outputs), Operating temperature: 0...+60 °C, for ELOP II Factory programming tool.

F30 011 (-20 °C) :Controller (20 digital inputs, 8 digital outputs), Operating temperature: -20...+60 °C, for ELOP II Factory programming tool

F30 014:Controller (20 digital inputs, 8 digital outputs), Operating temperature: -25...+70 °C (temperature class T1), Vibration and shock tested according to EN 50125-3 and EN 50155,

class 1B according to IEC 61373, for ELOP II Factory programming tool

F30 01 SILworX:Controller (20 digital inputs, 8 digital outputs), Operating temperature: 0...+60 °C, for SILworX programming tool

F30 011 SILworX (-20 °C):Controller (20 digital inputs, 8 digital outputs), Operating temperature: -20...+60 °C, for SILworX programming tool

F30 014 SILworX:Controller (20 digital inputs, 8 digital outputs), Operating temperature: -25...+70 °C (temperature class T1), Vibration and shock tested according to EN 50125-3 and EN 50155, class 1B according to IEC 61373, for SILworX programming tool

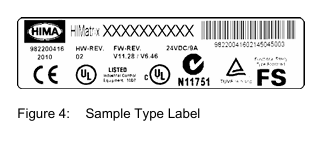

Type Label

The type plate contains the following details:

Product name

Bar code (1D or 2D code)

Part no.

Production year

Hardware revision index (HW Rev.)

Firmware revision index (FW Rev.)

Operating voltage

Mark of conformity

Mounting the F30 in Zone 2

(EC Directive 94/9/EC, ATEX)

The controller is suitable for mounting in zone 2. Refer to the corresponding declaration of conformity available on the HIMA website.

When mounting the device, observe the special conditions specified in the following section.

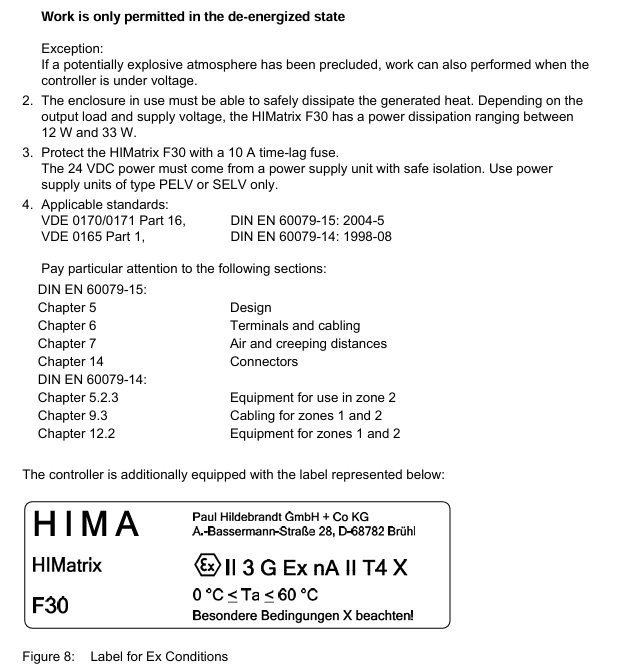

Specific Conditions X

1. Mount the HIMatrix F30 controller in an enclosure that meets the EN 60079-15 requirements and achieves a type of protection of at least IP54, in accordance with EN 60529. Provide the enclosure with the following label:

Work is only permitted in the de-energized state Exception:

If a potentially explosive atmosphere has been precluded, work can also performed when the controller is under voltage.

2. The enclosure in use must be able to safely dissipate the generated heat. Depending on the output load and supply voltage, the HIMatrix F30 has a power dissipation ranging between 12 W and 33 W.

3. Protect the HIMatrix F30 with a 10 A time-lag fuse.

The 24 VDC power must come from a power supply unit with safe isolation. Use power supply units of type PELV or SELV only.

4. Applicable standards:

VDE 0170/0171 Part 16, DIN EN 60079-15: 2004-5

VDE 0165 Part 1, DIN EN 60079-14: 1998-08

Configuration with SILworX

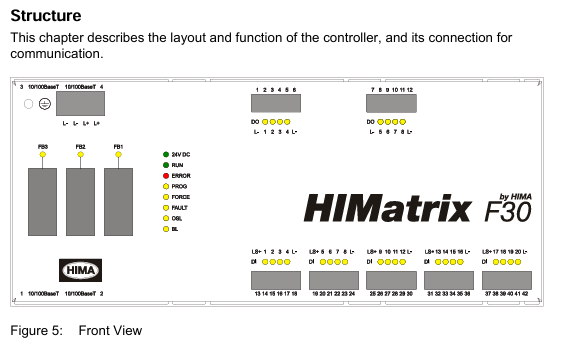

In the Hardware Editor, the controller is represented like a base plate equipped with the following modules:

Processor module (CPU)

Communication module (COM)

Input module (DI 20)

Output module (DO 8)

Double-click the module to open the Detail View with the corresponding tabs. The tabs are used to assign the global variables configured in the user program to the system variables.

Parameters and Error Codes for the Inputs and Outputs

The following tables specify the system parameters that can be read and set for the inputs and outputs, including the corresponding error codes.

In the user program, the error codes can be read using the variables assigned within the logic.

The error codes can also be displayed in SILworX.

Configuration with ELOP II Factory

Configuring the Inputs and Outputs

The signals previously defined in the Signal Editor (Hardware Management) are assigned to the individual channels (inputs and outputs) using ELOP II Factory. Refer to the system manual for compact systems or the online help for more details.

The following chapter describes the system signals used for assigning signals in the controller.

Signals and Error Codes for the Inputs and Outputs

The following tables specify the system signals that can be read and set for the inputs and outputs, including the corresponding error codes.

In the user program, the error codes can be read using the signals assigned within the logic.

The error codes can also be displayed in ELOP II Factory.

Operation

The controller F30 is ready for operation. No specific monitoring is required for the controller.

Handling

Handling of the controller during operation is not required.

Diagnosis

A first diagnosis results from evaluating the LEDs, see Chapter 3.4.1.

The device diagnostic history can also be read using the programming tool.

Maintenance

No maintenance measures are required during normal operation.

If a failure occurs, the defective module or device must be replaced with a module or device of the same type or with a replacement model approved by HIMA.

Only the manufacturer is authorized to repair the device/module.

Faults

If the test harnesses detect safety-critical faults, the module enters the STOP_INVALID state and will remain in this state. This means that the input signals are no longer processed by the device and the outputs switch to the de-energized, safe state. The evaluation of diagnostics provides information on the fault cause.

Maintenance Measures

The following measures are required for the device:

Loading the operating system, if a new version is required

Executing the proof test

Loading the Operating System

HIMA is continuously improving the operating system of the devices.

HIMA recommends to use system downtimes to load a current version of the operating system into the devices.

Refer to the release list to check the consequences of the new operation system version on the system!

The operating system is loaded using the programming tool.

Prior to loading the operating system, the device must be in STOP (displayed in the programming tool). Otherwise, stop the device.

For more information, refer to the programming tool documentation.

Proof Test

HIMatrix devices and modules must be subjected to a proof test in intervals of 10 years.

Decommissioning

Remove the supply voltage to decommission the device. Afterwards pull out the pluggable screw terminal connector blocks for inputs and outputs and the Ethernet cables.

Transport

To avoid mechanical damage, HIMatrix components must be transported in packaging.

Always store HIMatrix components in their original product packaging. This packaging also provides protection against electrostatic discharge. Note that the product packaging alone is not suitable for transport.

Disposal

Industrial customers are responsible for correctly disposing of decommissioned HIMatrix hardware. Upon request, a disposal agreement can be arranged with HIMA.

All materials must be disposed of in an ecologically sound manner.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

75

+86-153-9626-8993

WeChat

Contact

Whatsapp

After years of experience, it has developed into a group enterprise entity integrating equipment, industrial, chemical, petroleum equipment, electricity and other products trade and services.

KONG JIANG

Product

Copyright © 2023 KongJiang Group All Rights Reserved .