REXRTOH INDRAMAT TVD 1.3 power module

Altitude adaptation: When the altitude exceeds 1000 meters, the power usage should be reduced according to the derating curve (such as reducing the power to 80% at 2000 meters).

Troubleshooting and Maintenance

1. Fault diagnosis and localization

The front panel of the module is equipped with LED diagnostic lights, which indicate the type of fault through different colors (green/red/flashing). The core faults and troubleshooting methods are as follows:

Fault type LED indication Possible causes Troubleshooting methods

Control voltage fault (+24V/± 15V)+24V/± 15V, red light, electronic power supply loss, load exceeding upper limit, check main fuse, disconnect bus to detect voltage, reduce load

Drive or power failure Bb1 red light drive module failure, loose bus connection check drive diagnosis, re plug and unplug bus cable, confirm terminal plug installation

Overcurrent fault I-FAULT light red DC bus short circuit, motor cable damage, disconnection of drive connection, detection of bus insulation, replacement of damaged cable or drive

Release overload P-FAULT light red regeneration energy over release capability, increase auxiliary release module (TBM), reduce driving and braking frequency

Overheating fault T-FAULT light red, poor heat dissipation, high ambient temperature. Clean the heat dissipation channel, improve cabinet ventilation, and reduce module load

Overvoltage fault U-FAULT light red grid voltage too high, rectifier circuit fault check grid voltage (≤ 480V ± 10%), replace module

2. Maintenance and replacement standards

Regular maintenance: Check the tightness of the wiring terminals and the cleanliness of the heat sink every 6 months, and measure the insulation resistance (≥ 10M Ω) annually;

Module replacement: After power off, wait for 5 minutes (capacitor discharge), confirm that there is no voltage, remove the wiring, replace with a module of the same model (matching power and version), and test the bus communication and voltage output after rewiring.

Selection and ordering information

1. Core component model

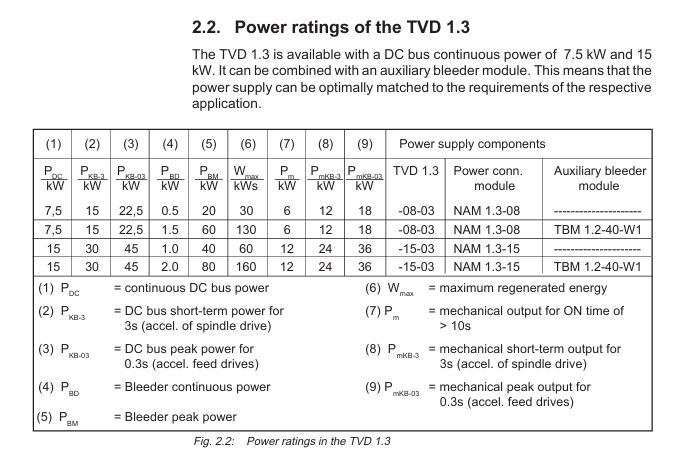

Component category, model, and specification description

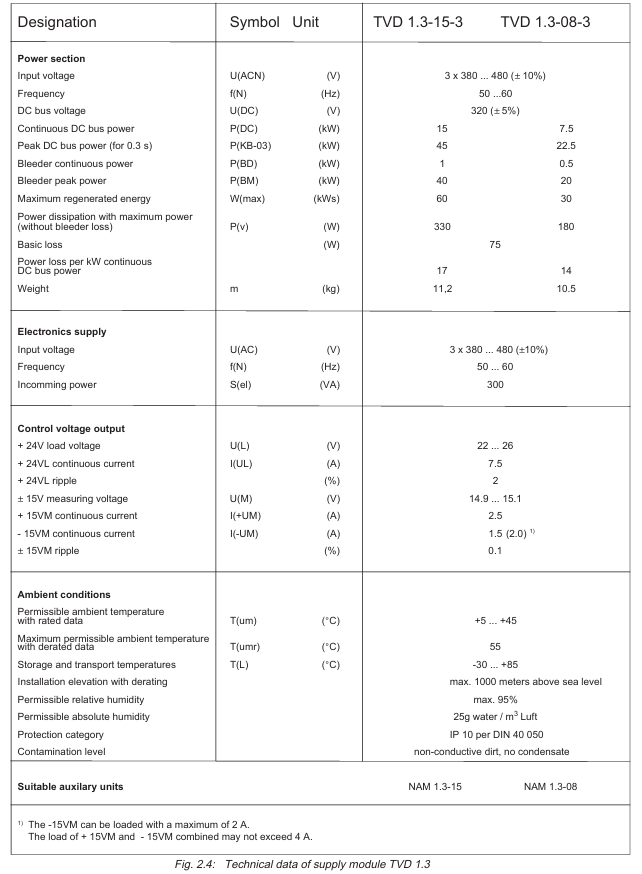

Power module TVD 1.3-08-3 7.5kW continuous DC bus power, 320V DC output

TVD 1.3-15-3 15kW continuous DC bus power, 320V DC output

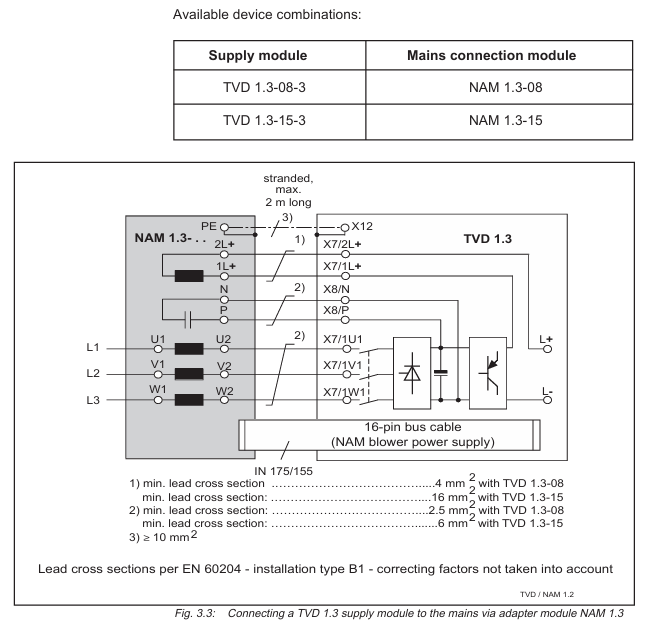

Integrated connection module NAM 1.3-08 compatible with TVD 1.3-08, including commutation choke/buffer capacitor

NAM 1.3-15 is compatible with TVD 1.3-15, including commutation choke/buffer capacitor

Auxiliary release module TBM 1.2-040-W1 enhances release capacity (1.5kW continuous/60kW peak)

Independent component KD 26/23 commutation choke (15A/30A)

CZ 1.2-01-7 Buffer Capacitor (1mF/700V)

GLD 16/17 DC bus flat wave choke coil (25A/50A)

2. Ordering precautions

The power module should be selected based on the total power of the drive (continuous power should cover the sum of the rated power of all drives);

If the drive frequently starts, stops, or brakes, an additional auxiliary release module (TBM) or DC bus capacitor needs to be configured;

High altitude (>1000 meters) or high temperature (>40 ℃) environments require the selection of downgraded models or strengthened heat dissipation measures.

Safety and Compliance Instructions

Hazardous Area Use: Only applicable to Class I, Zone 2 hazardous environments (non flammable areas), prohibited for use in explosive environments;

Voltage safety: There is a maximum of 450V DC high voltage inside the module. After power failure, it is necessary to wait for 5 minutes for discharge, and only certified electricians are allowed to operate;

Compliance standards: comply with UL standards, DIN 40050 (protection level), EN 60204 (electrical installation) and other specifications, and confirm the compatibility with local electrical regulations before use.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor