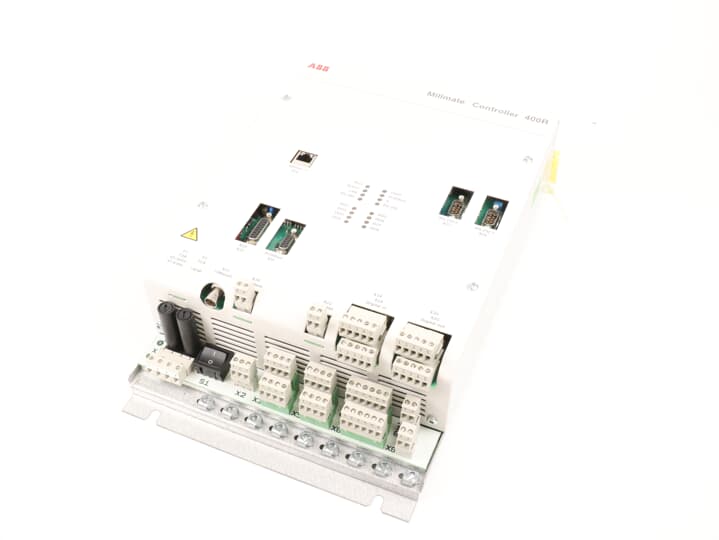

ABB PFXA401SF as a unit module

ABB PFXA401SF as a unit module

ABB PFXA401SF is an operating unit designed for advanced industrial automation control systems, demonstrating powerful performance and reliable operation in various industrial environments. It aims to improve the efficiency and reliability of industrial processes. With intuitive design and high-resolution display screens, it can clearly present process parameters, assist operators in making better decisions, and achieve more efficient operation supervision.

Performance characteristics

Multiple control modes: supports position control, speed control, and torque control, and can seamlessly switch between any two control modes. In practical applications, such as in the motion control of robotic arms in automated production lines, when the robotic arm needs to quickly move from one position to another, speed control mode can be used to quickly reach the target area, and when approaching the target position, switch to position control mode to achieve precise positioning; When transporting items of different weights, the torque control mode ensures that the robotic arm provides appropriate force to grip and transport the items, ensuring stability and accuracy of the operation.

High response frequency: It has achieved a speed response frequency of up to 400Hz, which enables the device to quickly respond to rapidly changing control commands. Taking high-speed textile machinery as an example, in the production process, the tension of the yarn needs to be quickly adjusted according to different production processes and product requirements. The high-speed response frequency of PFXA401SF can adjust the motor speed in a timely manner to ensure the stability of the yarn tension, thereby improving product quality and production efficiency.

High precision positioning: Using advanced digital control algorithms to precisely control the current loop, speed loop, and position loop, ensuring fast and accurate positioning. In semiconductor manufacturing equipment, the processing and assembly of chips require extremely high positioning accuracy. PFXA401SF can meet this requirement, ensuring the positional accuracy of chips during processing and assembly, reducing scrap rates, and improving product quality and production efficiency.

Functional characteristics

Flexible configuration interface:

Equipped with 2 high-speed pulse inputs, with a maximum frequency of 500KHz, it can quickly receive pulse signals sent by external devices, achieving precise position and speed control. For example, on CNC machine tools, by receiving high-speed pulse signals from encoders, PFXA401SF can accurately control the movement position and speed of the machine tool worktable, ensuring machining accuracy.

2-channel 12 bit high-precision -10V~10V analog input, can be used to collect various analog signals, such as voltage signals output by sensors, for monitoring and controlling physical quantities such as temperature, pressure, flow rate, etc. in industrial processes. For example, in chemical production, PFXA401SF can monitor the temperature inside the reactor in real time by collecting analog signals from temperature sensors, and accurately control it according to the set value to ensure that chemical reactions proceed under appropriate temperature conditions.

7 DI (digital input) inputs and 3 DO (digital output) outputs, all of which can be freely defined for easy connection and communication with various external devices. For example, in an automated warehouse system, DI ports can be connected to cargo sensors to detect the position and status of goods, while DO ports can control the start and stop of motors and the opening and closing of valves, achieving automated storage and handling of goods.

It also has 3 encoder differential signal outputs and 1 Z-phase origin signal transistor output, which are used to cooperate with encoders and other devices to achieve more accurate position detection and control. In the elevator control system, PFXA401SF can monitor the position and operating status of the elevator in real time by connecting with the encoder on the elevator car, ensuring the safe and stable operation of the elevator.

Dual communication port design:

Communication port 1 can support online debugging of the upper computer PC, making it convenient for engineers to set system parameters, download programs, and diagnose faults. During the equipment installation and debugging phase, engineers can connect to PFXA401SF through a PC to quickly set equipment parameters and ensure normal operation of the equipment.

Communication port 2 has two interface modes, RS232 and RS485, and supports Modbus RTU communication protocol, which enables it to communicate with various devices and facilitate integration into different industrial networks. In the construction of smart factories, PFXA401SF can form a Modbus network with other devices through RS485 interface, realizing data sharing and interaction, and achieving automation control and management of the entire production process.

Braking function: Equipped with a built-in braking transistor, it can meet applications with high load inertia or short deceleration time. In large equipment such as cranes, when the goods need to stop quickly, the braking function of PFXA401SF can quickly stop the motor from rotating, avoiding the swinging or sliding of the goods due to inertia and ensuring the safety of operation.

Other functions:

It has three digital signal input ports, which are used for pulse/direction/enable signals, with an input voltage range of 5-24VDC, and adopts optoelectronic isolation technology to effectively prevent external interference signals from affecting the equipment, improving the stability and reliability of the system.

By using the dip switch, 8 levels of subdivision can be selected, with subdivision accuracies of 400, 800, 1600, 3200, 6400, 1200, 1800, 256, 500, and 1200 respectively. Suitable subdivision accuracies can be selected according to different application requirements to improve the smoothness and control accuracy of motor operation. For example, in 3D printers, by selecting the appropriate subdivision accuracy, the print head can move more smoothly and print finer models.

By using the dip switch, 8 levels of current can be selected, with current values of 1.0A, 1.5A, 2.0A, 2.5A, 3.0A, 3.5A, 4.0A, and 4.5A respectively. The output current can be adjusted according to the actual needs of the motor to ensure that it can operate normally under different load conditions, while also protecting the motor.

Equipped with a rotary switch for selecting motor parameters to match the current control algorithm, achieving optimal motor performance. In practical applications, engineers can select appropriate motor parameters through rotary switches based on factors such as motor type and load characteristics, allowing PFXA401SF to better match the motor and achieve optimal performance.

Equipped with automatic current reduction function, the current reduction ratio can be selected as 50% or 90% through the dip switch. During the operation of the equipment, when the motor is in a light load or no-load state, the output current will be automatically reduced to achieve energy saving. For example, in some devices that work intermittently, when the device pauses, PFXA401SF automatically reduces the current output to reduce energy consumption.

Equipped with self checking function, it can monitor the operating status of the equipment in real time. When a fault is detected, it will promptly issue an alarm and take corresponding protective measures, such as overvoltage, undervoltage, overcurrent, motor open circuit detection, etc., effectively protecting the safe operation of the equipment and the entire system. In industrial production, once abnormal voltage or excessive current occurs, PFXA401SF can quickly cut off the power supply, avoiding equipment damage and production accidents.

Compatibility with ABB control system

This unit is compatible with multiple ABB control systems, ensuring seamless integration into existing infrastructure. Its strong compatibility enables upgrading or retrofitting existing industrial automation systems without the need for large-scale equipment replacement. Simply connect PFXA401SF to the existing ABB control system network to achieve functional expansion and performance improvement, greatly reducing the cost and complexity of system upgrades.

Applicable environment and reliability

Applicable environment: Its sturdy structure and reliable power supply make it suitable for demanding industrial environments, where normal operating time and accuracy are crucial. Whether it is a chemical production workshop with high temperature and humidity, or a mining site with high dust and strong electromagnetic interference, PFXA401SF can operate stably, ensuring the continuity and stability of industrial production.

Reliability: In terms of hardware design, high-quality electronic components and sturdy casing materials are used to improve the anti-interference ability and mechanical strength of the equipment; In terms of software algorithms, strict testing and optimization are carried out to ensure the accuracy and stability of control. At the same time, its modular design not only facilitates installation and configuration, but also enables quick positioning and replacement of faulty modules in case of equipment failure, reducing downtime and further improving the reliability and maintenance convenience of the system.

Energy efficiency

PFXA401SF only consumes 8V · A of power, which makes it highly energy-efficient and cost-effective in the long run. In today's increasingly tense energy environment, enterprises are paying more and more attention to the energy efficiency of equipment. The low-power design of PFXA401SF not only helps enterprises reduce energy consumption costs, but also conforms to environmental protection concepts and contributes to sustainable development. In some large industrial enterprises, the energy consumption of a large number of equipment is a significant expense. Adopting low-power devices such as PFXA401SF can effectively reduce the operating costs of the enterprise.

Application Fields

Due to its advanced functionality and reliable performance, PFXA401SF is suitable for many industries that require precise control and monitoring solutions, including manufacturing, petrochemicals, power generation facilities, and more.

Manufacturing industry: In the automotive manufacturing production line, PFXA401SF can be used to control the movement of robotic arms and achieve precise assembly of automotive components; In electronic product manufacturing, it can be used to control the operation of SMT surface mount machines to ensure accurate placement of electronic components.

Petrochemical industry: In the process of petroleum refining, it can be used to control the operation of various pumps and valves, achieving precise control of parameters such as petroleum flow rate and pressure; In chemical production, it can be used to monitor and control process parameters such as temperature and pressure of reaction vessels, ensuring the safe and stable progress of chemical reactions.

Power generation facilities: In thermal power plants, they can be used to control the speed and power of steam turbines, achieving efficient power generation; In wind farms, it can be used to control the blade angle and speed of wind turbines, improving the efficiency of wind energy utilization.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor