TOSVERT VF-AS3 series 600V industrial frequency converter

TOSVERT VF-AS3 series 600V industrial frequency converter: in-depth technical analysis and comprehensive application guide

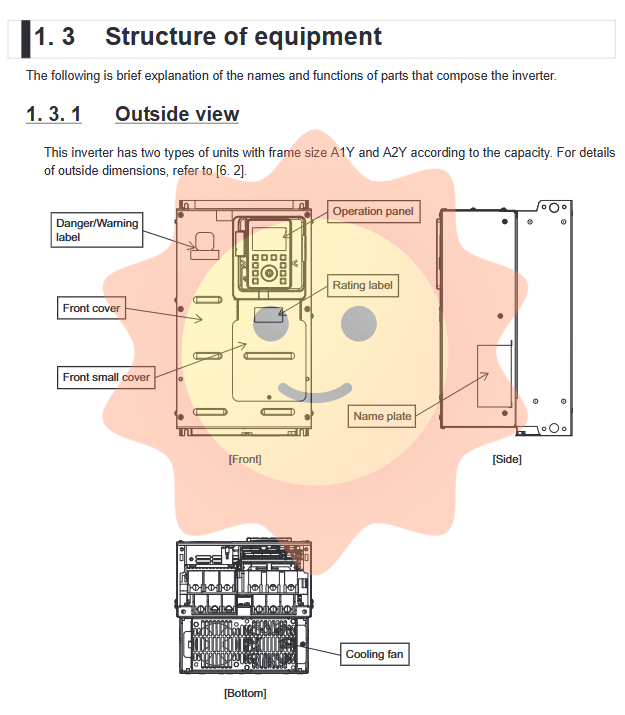

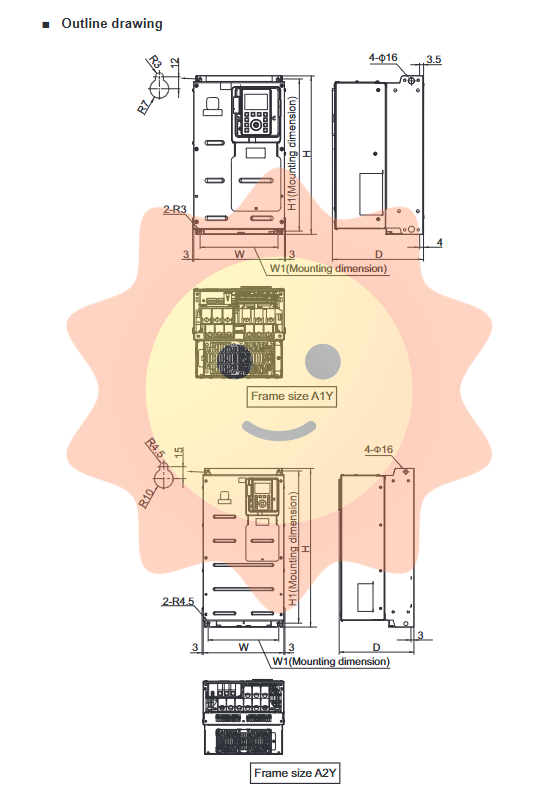

In the field of industrial automation and motor control, the performance, reliability, and safety of frequency converters are crucial as the core driving equipment. Toshiba's VF-AS3 series industrial frequency converters are designed specifically for three-phase induction motors, built-in and surface mounted permanent magnet synchronous motors, and are suitable for a wide range of industrial scenarios. This article is based on the official technical manual, providing a systematic and professional technical analysis and application explanation of the 600V level products in this series. It covers key content such as product overview, safety specifications, installation and wiring, parameter settings, compliance standards, and maintenance, aiming to provide a comprehensive and in-depth reference guide for engineering design, installation, commissioning, and maintenance personnel.

Product Overview and Core Design Philosophy

The VF-AS3 series frequency converter is a high-performance motor driver designed for general industrial applications. The core design concept is to provide a flexible, efficient, and safe motor speed control solution. The product supports multiple voltage levels of 500V, 600V (575V), and 690V, and has multiple rated value selection functions. Users can choose between heavy load or normal load rating based on load characteristics (constant torque or variable torque), thus achieving the best matching and application optimization of the equipment. This series of products adopts sine wave PWM control technology, providing precise frequency and torque output, and built-in rich control functions such as PID regulation, multi-stage operation, automatic torque boosting, etc., to meet complex process requirements.

Critical safety operation standards

Safety is the primary prerequisite for the use of equipment. The manual prominently emphasizes safety precautions and adopts the internationally recognized three-level identification system of "warning", "caution", and "prompt" to clarify the possible consequences of different operational errors.

Electrical safety: It is strictly prohibited to remove the front cover or contact terminals while powered on. There are high-voltage components inside, which pose a fatal risk of electric shock. Before any wiring or maintenance, all input power must be cut off and wait for at least 15 minutes until the charging indicator light goes out, and use an instrument to confirm that the DC bus voltage has dropped to a safe level (below 45V DC).

Fire prevention and equipment safety: It is forbidden to connect the power supply to the motor output terminal, and it is forbidden to incorrectly connect the braking resistor between the DC terminals, otherwise it may cause equipment damage or fire. Suitable short-circuit protection devices and ground leakage protectors must be installed on the power supply side. The frequency converter needs to be installed on a metal backplate, away from flammable materials and liquids.

Personal and mechanical safety: Two or more people are required to cooperate when transporting aircraft weighing over 20kg, and a crane is required for heavy machinery. The installation location should be able to withstand the weight of the equipment and avoid high vibration environments. During operation or after power failure, the motor may rotate due to inertia and generate high voltage at the output end. Touch is prohibited. Before resetting the fault, it is necessary to confirm that the operation command has been turned off to prevent accidental motor start-up and injury.

Environmental and usage restrictions: Clearly state that the product is suitable for general industrial use and cannot be used in situations with special safety requirements such as nuclear energy, aviation, life support, etc. It is strictly prohibited to drive single-phase motors.

Installation, wiring, and environmental requirements

Correct installation and wiring are the foundation for ensuring the long-term stable operation of the frequency converter.

Installation environment:

Temperature: The operating environment temperature ranges from -15 ° C to+60 ° C. When the ambient temperature exceeds 50 ° C, the rated output current needs to be reduced or the operation panel needs to be removed and installed separately (the operation panel contains a lithium battery, which poses a risk of high temperature).

Humidity and pollution: Relative humidity of 5% -95% (no condensation), pollution level of 2. It should be avoided to install in places with high dust, metal shavings, oil mist, corrosive gases, or where there is a risk of condensation or freezing.

Space and heat dissipation: Adequate heat dissipation space should be ensured during installation. When multiple frequency converters are installed side by side, the minimum spacing is 11mm, but it is recommended to reserve more space at the top and bottom to facilitate air duct circulation. The manual provides detailed heat generation data and calculation tables for the required ventilation volume for forced air cooling of cabinets and the required heat dissipation surface area for sealed cabinets.

Power and motor wiring:

Power requirement: The allowable fluctuation range of input voltage is+10% to -15% of the rated voltage (+10% during full load continuous operation). Copper wires that meet the specifications must be used.

Grounding: It is necessary to use wires with sufficient cross-sectional area and not less than the specifications of the power cord to reliably connect the grounding terminal of the frequency converter to a dedicated grounding electrode. This is a key measure to prevent electric shock and fire.

Wiring technique: The input power line, output motor line, and control line should be laid separately to avoid parallel bundling and reduce electromagnetic interference. Suggest using shielded cables and grounding the shielding layer properly. It is recommended to use crimping terminals with insulated sleeves for power terminals and tighten them according to the torque specified in the manual.

Peripheral devices: Suitable fuses, circuit breakers, or leakage protectors must be installed at the power input end to achieve short-circuit and ground fault protection. The contactor coil needs to be equipped with a surge absorber.

Parameter setting and core function configuration

The VF-AS3 series frequency converter provides extremely rich parameters to achieve precise control.

Initial and multiple rating settings: Region selection is required for the first power on. The most crucial thing is to set the parameter<AUL>(multiple rated value selection) based on the actual motor voltage and load type used. For example, for a 600V (575V) system,<AUL>=2 is a normal load, and<AUL>=3 is a heavy load. Incorrect settings may cause the motor to overheat or malfunction.

Basic operating parameters: including operation command source (<CMOD>), frequency command source (<FMD>), maximum frequency (<FH>), upper and lower limit frequencies (<UL>/<LL>), acceleration/deceleration time (<ACC>/<dEC>), etc. These parameters determine the basic operating characteristics of the frequency converter.

Motor parameters and protection: It is necessary to correctly set the rated power, current, voltage, number of poles, and other parameters of the motor in order to enable accurate vector control or V/F control of the frequency converter. Electronic thermal protection functions (such as F601) can provide overload protection based on motor characteristics. For multi motor or special small capacity motor drives, external heating relays are required.

Carrier frequency and braking settings: The carrier frequency (<F300>) affects the quality of the output waveform, motor noise, and frequency converter temperature rise, and can be adjusted within the specified range. When using external braking resistors, corresponding braking parameters (<F304>,<F308>,<F309>) need to be set.

Advanced features: Supports PID closed-loop control, multi-stage operation, jump frequency, S-curve acceleration and deceleration, instantaneous stop and restart, load shedding control, etc. Users can flexibly implement various logical controls by assigning digital input/output terminals.

Compliance certification and electromagnetic compatibility

This series of products has taken into account the compliance requirements of major global markets in their design.

CE Mark and Directive: The product itself complies with the Low Voltage Directive and EMC Directive. The built-in EMC filter can meet the radiation and conducted emission requirements of IEC61800-3 Category C3 (EN55011 Class A Group 2) when the motor cable length does not exceed 25 meters (depending on the model and carrier frequency). To ensure that the final equipment meets the EMC directive, the manual recommends multiple measures, such as using shielded wires, installing the frequency converter in a metal cabinet, separating wiring, and installing magnetic rings on the grounding wire.

UL/CSA standard: The product has passed UL/CSA certification and has corresponding markings on the nameplate. To comply with UL61800-5-1, the original warning label on the front cover must be retained during installation, and UL certified wires and fuses must be used. The manual provides a detailed list of short-circuit current ratings, recommended fuse models, and wire specifications. When the installation altitude is above 1000 meters, the output current needs to be reduced by 1% per 100 meters.

Safety function: Supports the "safety torque shutdown" function that complies with IEC 61800-5-2, and can achieve higher safety level motor stop control through dedicated terminals.

Maintenance, upkeep, and lifecycle

Regular inspection: It is necessary to regularly check whether the fastening terminals are loose, clean the dust on the heat dissipation fins and ventilation openings, and check whether the cooling fan is running normally.

Cooling fan lifespan: The manual clearly states that the design lifespan of cooling fans used to cool heating components is approximately 8 years (VFAS3-6022PC to 6750PC). After reaching the end of its lifespan, it should be replaced promptly to prevent equipment overheating and damage due to poor heat dissipation.

Warranty Policy: The product warranty period is 12 months after purchase or 18 months after leaving the factory, whichever is earlier. The warranty scope is limited to malfunctions caused by manufacturing defects, and damages caused by misuse, improper installation, natural disasters, failure to operate or maintain according to manual requirements, etc. are not covered by the warranty.

Disposal: When products are scrapped, they should be treated as industrial electronic waste and recycled in accordance with local environmental regulations.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor