Toshiba TE3 Soft Starter Installation, Operation, and Maintenance Complete Guide

Toshiba TE3 series low-voltage digital solid-state soft starter

1. Product Overview and Safety Standards

The TE3 series low-voltage digital solid-state soft starter launched by Toshiba International Corporation covers a current range of 18A to 1250A and is suitable for various industrial motor control scenarios. This device adopts solid-state electronic technology, with soft start, soft stop, energy-saving operation, and multiple protection functions, significantly reducing mechanical and electrical stress during motor start-up.

In terms of safety, the manual clearly emphasizes that only qualified personnel are allowed to install, operate, and maintain. Qualified personnel must have knowledge and safety training experience related to electrical equipment, be familiar with equipment structure, motor load characteristics, and on-site hazard identification ability. Any electrical or mechanical modification without Toshiba's written consent may result in the invalidation of warranty, safety certification, and even personal injury or equipment damage.

Equipment installation must comply with the National Electrical Code (NEC), Occupational Safety and Health Administration (OSHA), and relevant local regulations in the United States. The installation location should be easy to operate and maintain, and kept away from flammable and corrosive environments. The equipment grounding must be reliable, and metal conduits cannot be used as grounding paths. A separate grounding wire must be laid.

2. Mechanical installation and environmental requirements

The TE3 soft starter should be installed on a flat, vertical surface and ensure that the top of the equipment is facing upwards. The installation position should reserve sufficient front operating space and avoid adjacent high heat source equipment.

2.1 Cabinet ventilation and heat dissipation calculation

If TE3 is installed inside the cabinet, the required ventilation should be calculated based on the device's heat dissipation. The heat dissipation power (Watt) can be estimated by the following formula:

During the startup process:W=1200Istart×tstart×Nstarts/hou

When iERS function is disabled:W=Irated×0.6

When iERS function is enabled:W=Irated×1.5

Required ventilation volume:Q= T max−T amb/4×W

The maximum allowable temperature inside the cabinet (usually 50 ℃),

For the inlet air temperature.

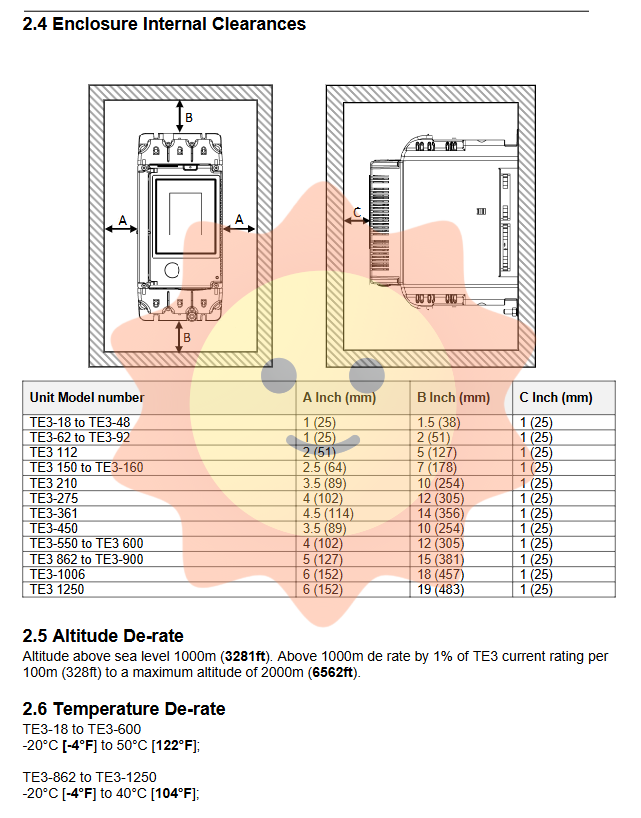

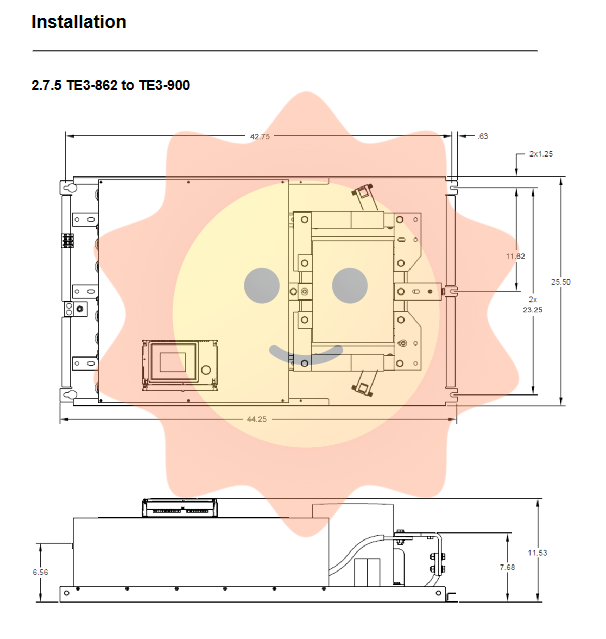

2.2 Installation spacing and derating requirements

The minimum distance should be maintained around the equipment (see Table 2.4 in the manual) to ensure heat dissipation and safe operation. In high-altitude (over 1000 meters) or high-temperature environments, the rated current of the equipment needs to be reduced:

When the altitude is above 1000 meters, the weight decreases by 1% for every 100 meters increase, up to a maximum of 2000 meters;

When the ambient temperature exceeds 40 ℃, adjustments should be made based on the temperature current derating curve.

3. Electrical installation and wiring specifications

3.1 Power and control wiring

The input power supply, output power supply, and control circuit should be laid separately in independent metal conduits, and each conduit should contain an independent grounding wire. If parallel wires are used, each group of parallel wires should be laid separately and the same conduit should not be mixed.

Warning: All power sources must be disconnected and locked before wiring, following the lockout/tagout procedure. Do not connect the three-phase input power supply to the output terminal of the soft starter, otherwise it may cause equipment damage or personal injury.

3.2 Control power supply and terminal instructions

The control power supply voltage is 120-240V AC, and the specific voltage needs to be confirmed according to the model. The digital input terminals (DI1-DI4) support 120V AC, 240V AC, or 24V DC and must be matched with the actual input voltage in the parameter settings, otherwise it may damage the equipment.

The relay output terminals (DO1-DO5) can be used to indicate operating status, faults, startup completion, etc., supporting a maximum load of 240V AC/1-3A.

4. Parameter settings and operating modes

TE3 offers three configuration options: touch screen, remote touch screen, and Modbus RTU. Users can quickly match common load types (such as pumps, fans, compressors, etc.) through "automatic settings", or adjust parameters item by item through "advanced settings".

4.1 Automatic Setting Function

The device has dozens of built-in application presets, and users only need to select the load type (such as centrifugal pump, conveyor belt, compressor, etc.). The system automatically configures parameters such as start/stop time, current limit, trip level, etc., greatly simplifying the debugging process.

4.2 Key parameter description

Starting current limit: usually set at 350% of the motor's full load current to prevent starting overcurrent.

Stop current limit: used for torque control during soft stop process.

Trip level: Supports Class 10, 20, and 30, corresponding to different overload protection curves.

IERS intelligent energy-saving system: By adjusting the motor voltage to reduce energy consumption under light load, the energy-saving rate can reach 20% -40%.

4.3 Automatic Reset Function

TE3 supports automatic fault reset, and users can set the reset delay time, reset attempt times, and reset objects (such as overload, phase loss, communication timeout, etc.). This feature is particularly suitable for unmanned or remote monitoring scenarios.

5. Communication and Monitoring

5.1 Modbus RTU Integration

The device comes standard with RS-485 interface (RJ45) and supports Modbus RTU protocol, making it easy to connect to PLC or SCADA systems. Communication settings include station address (1-32), baud rate (9600-115200), and checksum.

The supported function codes include:

03: Read and hold register

06: Writing to a single register

16: Write multiple registers

5.2 Data Monitoring and Logging

TE3 monitors real-time parameters such as three-phase current, voltage, power, power factor, and radiator temperature, and records the peak current, temperature, and overload percentage of the last 10 starts/stops. The fault log can store the last 10 tripping events for easy fault tracing and analysis.

6. Fault diagnosis and maintenance

6.1 Common fault codes

101-117: Power side phase loss

201: Overheating of radiator

301-358: Thyristor triggering fault

601: Control voltage too low

1201/1202: Start/stop current limit timeout

1301/1302: Overload tripping

1701-1704: Communication failure

6.2 Maintenance Suggestions

Conduct a comprehensive inspection at least once a year, including wiring tightness, radiator cleanliness, and fan operation status.

In harsh environments, the frequency of inspections should be increased.

If the device emits smoke, odors, or abnormal sounds, the power should be immediately turned off.

It is strictly prohibited to connect power factor correction capacitors at the output end of the soft starter, otherwise it may cause equipment misoperation or damage.

7. Firmware upgrade and remote installation of touch screen

TE3 supports firmware upgrade via USB flash drive. The touch screen can be disassembled and remotely installed on the cabinet door, with two types of connecting cables of different lengths as standard to adapt to different installation distances.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor