Technical Analysis and Application of Toshiba V-Series Integrated Control System

Toshiba V-Series Integrated Control System: Comprehensive Analysis of Technical Architecture, Module Functions, and Industry Applications

The Toshiba V-series integrated control system is a high-performance distributed control system (DCS) that integrates sequential control, loop control, and computer control. It was introduced and promoted by Tianjin Zhonghuan Automation Technology Control Equipment Co., Ltd. This system has been widely used in industrial fields such as petroleum, chemical, power, metallurgy, and water treatment due to its flexible structure, high-speed data processing capabilities, reliable network architecture, and rich module options.

System Overview and Architecture Features

The V series system is centered around a controller and supports the free combination of sequential control modules (S module), loop control modules (L module), and computer modules (C module), achieving full coverage from simple logic control to complex process management. The system adopts a three-layer network architecture:

Monitoring and management network: based on Ethernet, connecting operator stations and monitoring devices;

Control network: supports high-speed networks such as TC net, TOSLINE-S20/S20LP, FL net, etc., to achieve real-time data exchange between controllers;

I/O fieldbus network: supports protocols such as DeviceNet and Profibus to connect field devices and sensors.

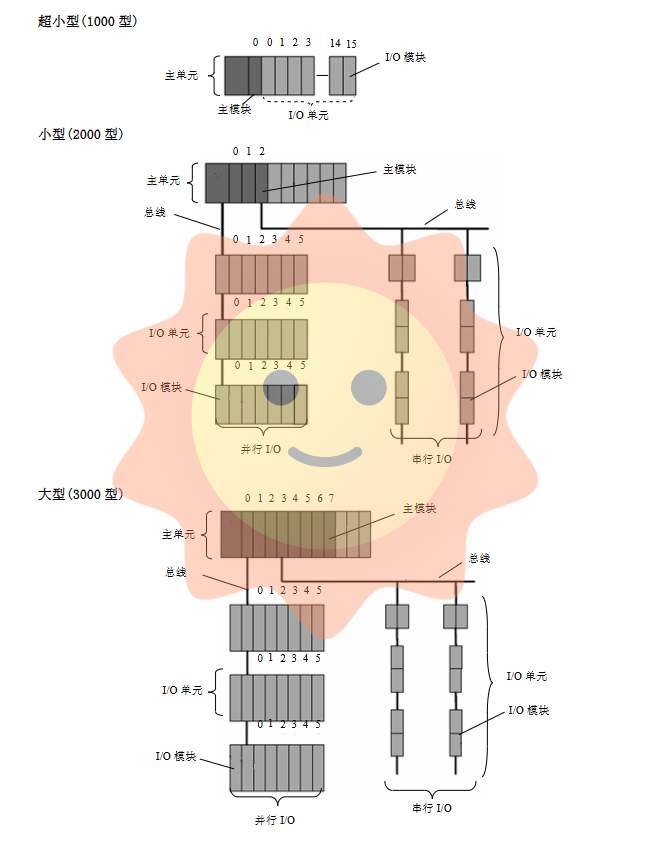

The system supports multi-scale configurations ranging from ultra small (MODEL 1000) to large (MODEL 3000), and can be flexibly selected based on the number of control points, processing speed, and redundancy requirements.

Detailed explanation of core module functions

1. Main control module

Sequential Control Module (S Module): Suitable for high-speed logic control, supports IEC language, processing speed up to 40ns, suitable for mechanical control, production line automation and other scenarios.

Loop control module (L module): Integrated with Toshiba's self-developed 2D degree of freedom super PID algorithm, suitable for high-precision process regulation such as boiler control and combustion control.

Computer module (C module): Based on the Windows system, supporting OPC servers and web services, suitable for data management, monitoring and scheduling, and system integration.

2. Communication module

Ethernet module: supports 10/100Mbps network and is suitable for monitoring layer data transmission;

TC net 100 module: designed specifically for MODEL 3000, with a transmission rate of 100Mbps and support for redundant configuration;

TOSLINE-S20/S20LP and FL net modules: suitable for high-speed communication and multi station collaboration between controllers;

DeviceNet/Profibus module: realizes standardized connection with field devices.

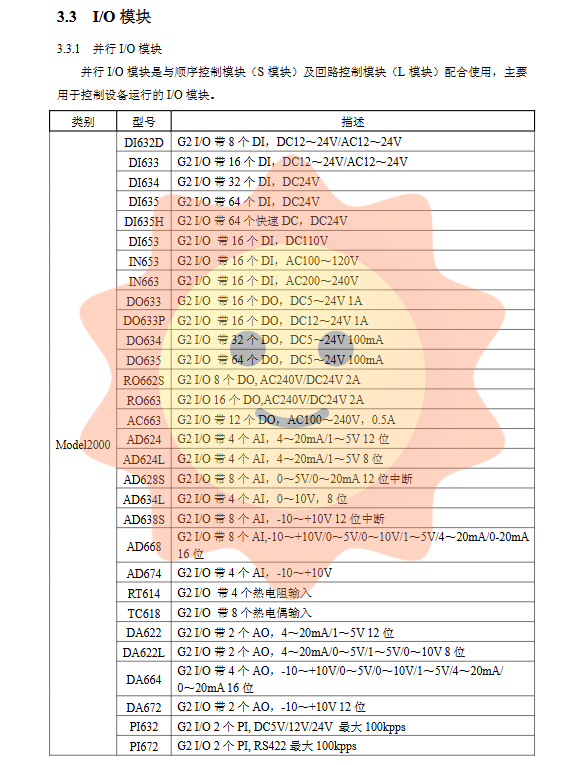

3. I/O module

Parallel I/O modules: digital, analog, and pulse input/output modules, supporting multi point expansion;

Serial I/O module: suitable for process control, supporting signal types such as thermistor and thermocouple.

Comparison and Application Scenarios of Three Models

1. MODEL 3000 (Large System)

Suitable for large-scale, high complexity control scenarios, such as steel rolling, large-scale chemical plants, power stations, etc;

Supports up to 8 main modules, redundant configurations, and high-speed networks;

The program has a capacity of 112K steps and supports up to 32 control stations and 22 human-machine interface stations.

2. MODEL 2000 (small and medium-sized systems)

Suitable for medium-sized control systems, such as small and medium-sized water treatment, light industry automation, environmental protection equipment, etc;

Flexible module configuration, supporting multiple network protocols;

Moderate price, balanced performance, suitable for most industrial scenarios.

3. MODEL 1000 (ultra small system)

Suitable for simple loop control and small-scale logic control, such as small boilers and single machine equipment control;

Compact structure, simple configuration, and low cost;

Supports communication between Ethernet and TOSLINE-S20LP.

System software and human-machine interface

The V series is equipped with the V-tool engineering tool, which supports IEC 61131-3 standard programming and has functions such as symbol editing, tag management, online debugging, and system logging. The human-machine interface is based on the OIS-DS system and supports:

Public tag database, achieving seamless integration between engineering tools and monitoring systems;

Client/server architecture, supporting distributed task processing;

Remote monitoring and internet access functions;

Redundant configuration and high availability design.

Industry application and integration advantages

The system has been successfully applied to:

Petrochemical industry: oilfield control, fertilizer plant process management;

Electric energy: power station monitoring, substation automation;

Metallurgical manufacturing: blast furnace control, continuous rolling system;

Environmental protection and water treatment: desulfurization control, sewage treatment, water plant monitoring;

Light Industry and Food: Control of Paper and Beer Production Lines.

The Toshiba V series integrated control system, with its openness, scalability, and high reliability, can not only be used as an independent DCS system, but also integrated with SCADA platforms such as FIX and Citect. It supports OPC protocol and enables enterprise level data sharing and system interconnection.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor