TOSHIBA Unified Controller nv series™ Unified Controller nv series™

Toshiba Unified Controller NV Series Type1 Light: The Next Generation Flexible and Reliable Control Platform for Critical Infrastructure

In the fields of modern industrial automation, urban infrastructure, and process control, the flexibility, reliability, and long-term maintainability of control systems are crucial. Faced with increasingly complex control and asset protection requirements, Toshiba Infrastructure Systems and Solutions has launched the Unified Controller nv series ™ The Type1 light controller, as an upgraded evolution of the second-generation V2000 CPU module, not only inherits the stable genes of mature architecture, but also achieves significant breakthroughs in performance, networking, and standardization, becoming a solid control cornerstone for building future factories and smart cities.

1、 Product Core Concept: FLEXIBLE, RELIABLE, STANDARDIZED

The design of the type1 light series revolves around three core pillars, aimed at addressing the fundamental pain points of industrial users:

Flexibility: Adopting TCnet based on the global real-time Ethernet standard IEC 61784-2 ™ The High Speed Serial I/O System of Technology - TC net ™ I/O。 This is a highly flexible remote I/O system that can connect I/O devices distributed across a wide area and multiple platforms at speeds of up to 100Mbps through a highly anti-interference fiber network, making it easy to build large-scale distributed control systems.

RELIABLE: Given the criticality of infrastructure, industrial production lines, and process systems, type1 light prioritizes reliability from the outset of its design. Ensure hardware foundation through the use of high-quality IC chips and rigorous board level testing processes. For scenarios that require extreme reliability, a complete redundancy configuration scheme (type1 light D) is provided, which supports the duplication of CPU, power, network, and I/O systems, ensuring uninterrupted switching of the system in the event of a single point of failure and achieving the highest system availability.

Standardization&MIGRATION: Its programming software nV Tool fully complies with the IEC 61131-3 international standard and supports multiple languages such as ladder diagrams (LD), functional block diagrams (FBD), sequential functional diagrams (SFC), and structured text (ST), ensuring the reusability of program assets and the accumulation of design knowledge. More importantly, the type1 light controller is fully compatible with the sequential control module (S2/S2E/S2T) of the previous generation integrated controller V-series Model 2000 at the program level, achieving smooth migration and protection of existing assets, greatly reducing the cost and risk of system upgrades.

2、 Detailed explanation of the three major models: a complete spectrum from standard to redundant

The type1 light series offers three targeted models, covering the full spectrum requirements from simple logic control to large critical redundant systems.

1. Type1 light S: Standard sequential control module

Positioning: An economical and compact standard CPU that can directly replace V2000 S2E modules.

Core Features:

Program capacity: 32K steps.

Maximum local I/O connection: 32 points (based on G2 I/O).

Built in communication interface: 1 Ethernet (supporting Toshiba ASCII computer link protocol), 1 RS485, 1 USB programming port.

System configuration: Installed on standard V2000 I/O racks (3/5/8 slots) to form a compact local I/O system.

Applicable scenarios: Low cost upgrade solutions for controlling small and medium-sized standalone equipment and replacing old S2E systems.

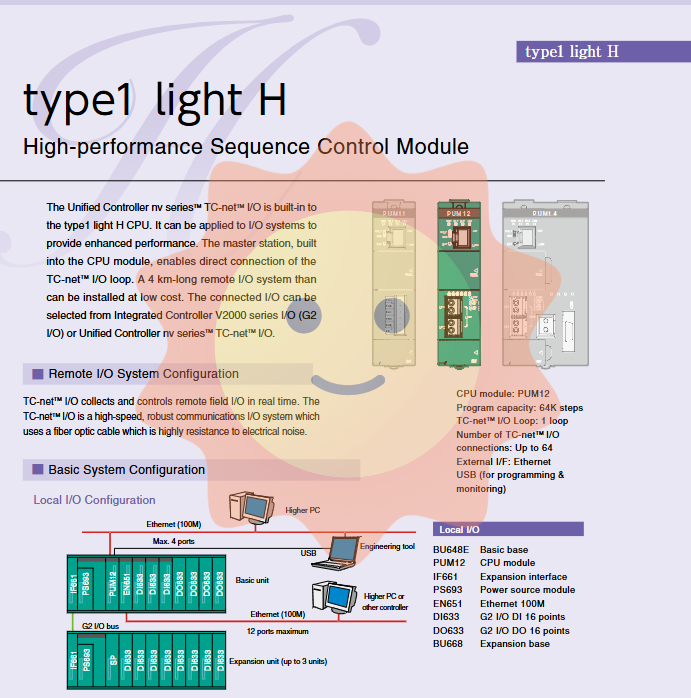

2. Type1 light H: High performance sequential control module

Positioning: A high-performance controller that integrates high-speed remote I/O master stations.

Core Features:

Program capacity: 64K steps.

Integrate 1 TC net ™ I/O loop, can directly connect to remote I/O, fiber optic loop up to 4 kilometers long.

Up to 64 TC net I/O modules can be connected, or V2000 G2 I/O can be mixed.

Built in Ethernet and USB interfaces.

System advantages: The perfect combination of powerful local processing capabilities and high-speed, noise resistant remote distributed I/O networks significantly reduces the cost of long-distance cabling and system integration, making it an ideal choice for achieving factory level distributed control.

3. Type1 light D: Redundant sequential control module

Positioning: A redundant control solution for medium to large critical systems.

Core Features:

Program capacity: 128K steps, the highest in the series.

Support a complete dual machine hot standby redundant system (CPU, tracking cable, power supply, etc.), automatically switching without disturbance in case of failure.

It can connect up to 192 I/O modules and control a large scale.

Also integrated with TC net ™ I/O loop.

Applicable scenarios: High reliability requirements for core processes in water treatment plants, oil and gas pipeline pump stations, centralized monitoring of tunnel clusters, and auxiliary systems in power plants that do not allow shutdown.

3、 Wide industry application verification

The Toshiba Type1 light controller has been successfully applied in multiple critical infrastructure fields worldwide due to its outstanding features

Water and sewage treatment: Build a flexible and scalable system architecture, utilizing wide area networks to achieve mutual monitoring and water quality assurance between pumping stations.

Oil and gas: To provide power and control for remote pumping stations, a fast and reliable fiber optic loop is used to achieve optical isolation and centralized parameter management of the drive.

Transportation infrastructure: used for wide area centralized monitoring of tunnel clusters, achieving efficient collaborative control of lighting dimming, emission ventilation, and emergency equipment.

Aviation system: applied to the ground lighting monitoring system of the terminal building, realizing high-speed light switching and collective intensity control, providing clear visual guidance for pilots.

Power generation (hydropower): used in dam management systems to ensure fault safety protection against gate misoperation through a dual data acquisition system, supporting manual or automatic motor drive control.

Material handling: Control the crane drive system to achieve sensitive control, efficient operation, and status visualization, relying on system reliability to ensure long-term stable use.

4、 Powerful engineering software support: nV Tool

A unified programming environment nV Tool is the key to unleashing the full potential of Type1 light.

Standardized programming: fully complies with IEC 61131-3, supports multi language mixed programming, and has an intuitive and easy-to-use graphical editor.

Advanced debugging features: online display of LD logic flow, FB values, SFC activation steps, providing synchronization trends, I/O forcing, data monitoring, and event logs, greatly simplifying troubleshooting.

Graphic customization: Custom graphic symbols (such as motor starters and valve controllers) can be created to replace standard functional blocks, making program logic clear at a glance.

Open Data Exchange: Supports importing/exporting projects that comply with the PLCopen XML standard, making it easy to port programs or split/merge projects between different controllers.

5、 Comprehensive specifications and environmental adaptability

The type1 light series strictly follows industrial environmental standards (IEC 61131-2, JIS B 3502):

Working temperature: 0~55 ° C.

Anti vibration/impact: meets the IEC 60068-2-6/27 standard.

Noise immunity: can resist pulse noise, static electricity, and radiation field interference.

Insulation and grounding: High insulation resistance, requiring Type D grounding (≤ 100 Ω).

Cooling method: Natural cooling, no need for fans, reducing failure points.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor