Toshiba VRF Dx coil interface device

Toshiba Carrier VRF DX-COIL Interface: An Intelligent Bridge Connecting Traditional AHUs with Modern Variable Frequency Multi Link Systems

The integration of traditional air handling units (AHUs) and advanced variable frequency multi link (VRF) systems has become a key factor in improving energy efficiency and control accuracy in commercial air conditioning and building ventilation systems. The VRF DX-COIL interface (model: TCB-IFDMX01UP-E/TCB-IFDMR01UP-E) launched by Toshiba Carrier is a specialized control device designed for such integrated scenarios. This interface enables the direct expansion coil (DX COIL) installed on site to seamlessly integrate into the Toshiba SMMS series VRF outdoor unit system, achieving direct expansion cooling/heating of refrigerant and supporting multiple control modes, greatly expanding the application boundaries of VRF systems.

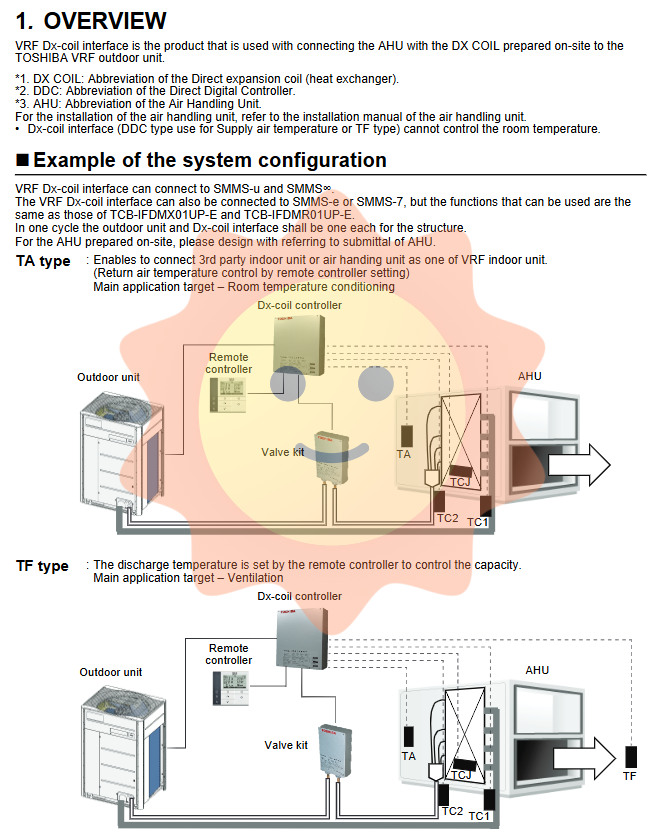

1、 Equipment Overview and System Architecture

The VRF DX-COIL interface is essentially a dedicated controller (DDC) that serves as the communication and execution unit between the VRF outdoor unit and the on-site AHU coil. Its core function is to receive capacity instructions from the VRF system, adjust the refrigerant flow rate by controlling the electronic expansion valve (PMV), and monitor parameters such as coil temperature and supply air temperature to achieve precise temperature control.

The system supports three main control types to adapt to different application scenarios:

TA type: Return air temperature control, suitable for space temperature control scenarios. Check the return air temperature through TA sensor, and adjust the compressor frequency and valve opening after comparing with the set value.

TF type: Supply air temperature control, suitable for scenarios with constant ventilation and supply air temperature. By monitoring the supply air temperature through TF sensors, precise control of the outlet air temperature can be achieved.

DDC type: Direct digital control, receiving capacity instructions from external DDC or building systems through 0-10V analog signals, achieving high integration linkage with the upper system.

The device supports compatibility with multiple series of outdoor units such as Toshiba SMMS-u, SMMS-i, SMMS-7, SMMS-e, etc. Each system is limited to one DX-COIL interface. Its design allows traditional fan coil units or customized wind cabinets to be upgraded to intelligent terminals that can be uniformly managed and allocated by VRF systems by installing this interface, significantly improving the overall IPLV and partial load efficiency of the system.

2、 Core control logic and protection functions

1. Capacity regulation and temperature control

The device executes different control strategies based on the selected type. The TA type is based on the deviation between the return air temperature (TA) and the set value (Ts), and adjusts the capacity demand signal sent to the outdoor unit through PID logic. The TF type is controlled based on the supply air temperature (TF). Both have the function of "forcing thermostat OFF", which automatically stops the cooling/heating demand when the return/supply air temperature reaches the set protection value (such as cooling TA ≤ 19 ℃, heating TA ≥ 15 ℃), to prevent excessive operation.

2. Multiple security and protection mechanisms

Antifreeze protection: By monitoring the coil temperature sensors TC1, TC2, TCJ, if the coil temperature is detected to be too low (entering the set low temperature zone) during refrigeration operation, the system will forcibly shut down the compressor and keep the fan running lightly until the temperature rises.

Cold air prevention: During heating start-up or operation, the fan speed is limited by monitoring the coil temperature (the higher value of TC1, TC2, TCJ) to avoid blowing cold air and improve comfort.

Refrigerant (oil) recovery control: When the system needs it, receive instructions from the outdoor unit, control the PMV to open for refrigerant or compressor oil recovery, and ensure long-term stable operation of the system.

3. Rich input/output (I/O) functions

The interface controller provides complete I/O ports for linkage with field devices:

Digital input (DI): including safety interlock (DI1), external fault (DI2), forced shutdown (DI3), notification code (DI4), operation mode switching (DI5), etc., supporting no voltage dry contact or DC12V signal input.

Digital Output (DO): Provides multiple relays (with relay models) or transistor outputs for operation, alarm, fan operation, defrosting, Thermostat ON, etc., used to drive external devices or indicate status.

Analog input (AI): AI1 is used for 4-20mA fan speed linkage control; AI3 is used for 0-10V external capacity control (DDC type) or temperature setting regulation (TA/TF type).

Analog output (AO): AO1 outputs a 0-10V fan speed control signal, which can be directly connected to a variable frequency fan driver.

3、 Key points for installation, configuration, and debugging

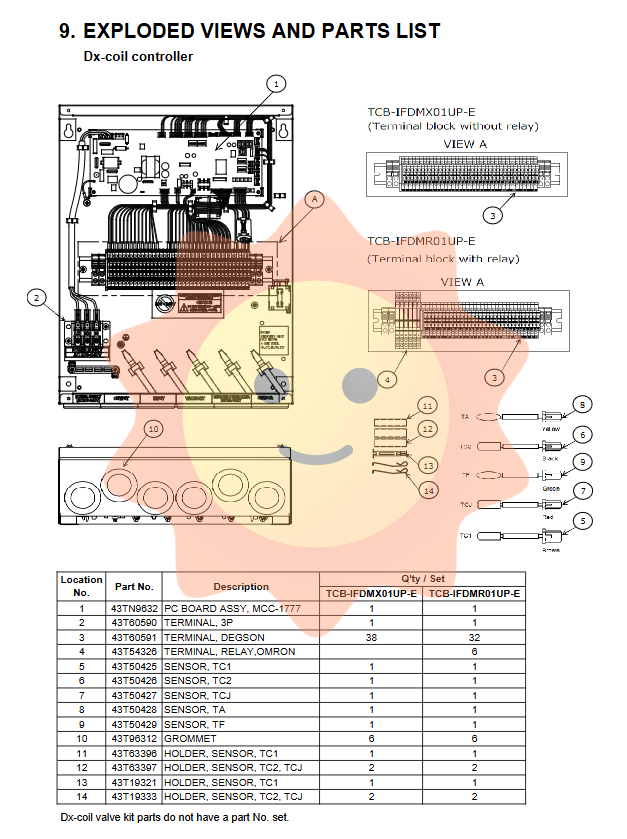

1. Refrigerant pipeline design and sensor installation

The equipment comes with RBM-A101UPVA-E or RBM-A201UPVA-E valve kit, which includes PMV valve body and coil. During installation, temperature sensors must be arranged strictly according to the manual requirements:

TC1: Welded on the gas manifold for monitoring the return gas temperature.

TC2: Installed between the liquid pipe distributor and PMV.

TCJ: Installed at the lowest temperature of the capillary tube.

TA/TF: Installed separately at the uniform airflow of the return air outlet and the supply air outlet.

The sensor installation requires the use of the attached welding storage seat, and the valve body needs to be cooled with a damp cloth during welding to prevent the temperature from exceeding 120 ℃.

2. Electrical wiring and settings

The controller motherboard (MCC-1777) allows key settings through dip switches (SW501-SW507, SW701, SW801):

SW501: Select control type (TA/TF/DDC) and DDC control mode (ladder/linear).

SW701: Switch DI1 safety interlock input to voltage type or non voltage type.

SW801: Set Modbus communication terminal resistance.

Attention should be paid to the separation of strong and weak electricity in wiring. PMV and sensor cables should not be tied to power cables, and the length of PMV cables should not exceed 5 meters.

3. DN code setting and debugging

The service mode can be entered through the wired remote control (RBC-ASCU11) to set key DN codes, such as:

DN11: Set the capacity code (corresponding to HP number) for the DX-COIL interface.

DN4AE: Set the valve kit model.

DN4A0-4A3: Set the threshold for 4-20mA fan linkage control.

Before debugging, an insulation test (≥ 1M Ω) should be conducted, and it should be ensured that the outdoor unit valve is fully opened. The trial operation requires entering the testing mode through the remote control to verify the cold and hot functions.

4、 Fault diagnosis and maintenance

The device has a complete self diagnostic function, and fault information is displayed in the form of inspection codes on the remote control, and historical records can be viewed through service mode. Common inspection codes include:

P10: Safety interlock (DI1) input exception.

L30: External fault (DI2) input activated, such as AHU fan failure.

F-class code: Various temperature sensor faults.

Maintenance personnel can quickly locate problems based on the code and carry out repairs using the troubleshooting process provided in the manual. The device also supports Modbus RTU communication (RS-485), making it easy to integrate into building management systems for remote monitoring and diagnosis.

5、 Safety regulations and professional requirements

The manual emphasizes the importance of job safety throughout, and all installation, maintenance, repair, and relocation work must be carried out by qualified installation or service personnel. Before operation, the power must be cut off and a warning sign must be hung. When working with refrigerants, local regulations must be followed, R410A special tools must be used, and good ventilation must be ensured in the working space to prevent suffocation or the production of toxic gases.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor