ABB 3BHE003604R0102 UFC765AE102 is a high-performance dedicated circuit board designed by ABB Group specifically for the core unit of industrial control systems. It is a key hardware component of ABB Symphony Plus or Advance OCS control systems, mainly responsible for core functions such as signal conditioning, logic operation, control instruction amplification, and equipment communication coordination. This circuit board serves as a bridge between signal processing and instruction execution in control systems, integrating high-precision analog circuits, high-speed digital logic circuits, and anti-interference protection circuits. It can achieve precise processing of various input signals and reliable execution of output instructions in complex industrial environments.

Compared with general industrial circuit boards, the UFC765AE102 circuit board has been customized and optimized for the demanding requirements of industrial control. It has outstanding performance in signal processing accuracy, anti-interference ability, operational stability, and compatibility with ABB control systems. It is widely used in large industrial plant control units in industries such as power, petrochemicals, metallurgy, etc., such as steam turbine control systems, boiler combustion control systems, and large motor speed control systems. It is the core hardware carrier to ensure the precise and stable operation of industrial control systems.

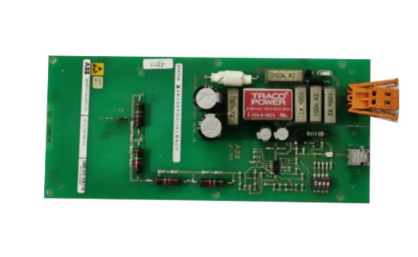

ABB 3BHE003604R0102 UFC765AE102 circuit board

Core Overview

ABB 3BHE003604R0102 UFC765AE102 is a high-performance dedicated circuit board designed by ABB Group specifically for the core unit of industrial control systems. It is a key hardware component of ABB Symphony Plus or Advance OCS control systems, mainly responsible for core functions such as signal conditioning, logic operation, control instruction amplification, and equipment communication coordination. This circuit board serves as a bridge between signal processing and instruction execution in control systems, integrating high-precision analog circuits, high-speed digital logic circuits, and anti-interference protection circuits. It can achieve precise processing of various input signals and reliable execution of output instructions in complex industrial environments.

Compared with general industrial circuit boards, the UFC765AE102 circuit board has been customized and optimized for the demanding requirements of industrial control. It has outstanding performance in signal processing accuracy, anti-interference ability, operational stability, and compatibility with ABB control systems. It is widely used in large industrial plant control units in industries such as power, petrochemicals, metallurgy, etc., such as steam turbine control systems, boiler combustion control systems, and large motor speed control systems. It is the core hardware carrier to ensure the precise and stable operation of industrial control systems.

Key characteristics

2.1 High precision signal conditioning and conversion capability

The UFC765AE102 circuit board is equipped with multi-channel high-precision signal conditioning units and analog-to-digital/digital to analog conversion modules, providing excellent signal processing performance. Its analog signal input channel supports 4-20mA current signal, 0-10V voltage signal, and thermocouple/thermistor signal acquisition. Through the built-in instrument amplifier and filtering circuit, it can effectively suppress noise interference during signal transmission, and the signal conditioning accuracy reaches 0.1% FS. The equipped 16 bit high-speed ADC (analog-to-digital converter) has a sampling rate of up to 500kHz and can quickly capture dynamically changing analog signals; A 16 bit DAC (Digital to Analog Converter) can accurately convert digital control instructions into analog output signals with an output accuracy of 0.05% FS, meeting the high-precision control requirements in industrial processes such as turbine speed regulation and boiler steam pressure control.

2.2 High speed digital logic operation and control

The circuit board is equipped with high-performance embedded microprocessors and programmable logic devices (FPGAs), with a main frequency of 300MHz. The FPGA uses Xilinx industrial grade chips and has powerful parallel computing capabilities. Through a fixed dedicated control algorithm, complex logic judgment, PID operation, interlock protection logic execution and other tasks can be achieved, with a response time of ≤ 10 μ s, which can quickly process instructions issued by the control system and drive actuator actions. At the same time, FPGA can flexibly configure the functions of digital I/O interfaces, support pulse signal capture, PWM signal output, etc., and adapt to different types of industrial control scenarios, such as motor start stop logic control, valve opening pulse adjustment, etc.

2.3 Comprehensive anti-interference and hardware protection design

In response to harsh conditions such as strong electromagnetic interference and voltage fluctuations in industrial sites, the circuit board has undergone comprehensive reliability optimization to ensure long-term stable operation

-Electromagnetic compatibility design: Adopting multi-layer PCB board design, analog circuit and digital circuit partition layout, key signal lines adopt differential routing and shielding treatment, in compliance with IEC 61000-4 series electromagnetic compatibility standards, ESD protection level reaches ± 8kV contact discharge and ± 15kV air discharge, which can effectively resist electromagnetic radiation and conducted interference in industrial sites.

-Signal isolation protection: All input and output channels adopt photoelectric isolation or magnetic isolation technology, with an isolation voltage of ≥ 2500V AC, to avoid the influence of external signal interference on the core circuit of the circuit board, and to prevent circuit board faults from affecting external devices.

-Power supply and overcurrent protection: equipped with a wide range power input unit (24V DC ± 20%), built-in power filtering, surge suppression, and overvoltage protection circuits; Each output channel is equipped with overcurrent protection fuses and short-circuit protection circuits. When the load experiences a short circuit or overload, the output circuit can be quickly cut off to protect the circuit board and external actuators from damage.

2.4 High compatibility and flexible expansion

The UFC765AE102 circuit board adopts ABB standard board interface design, which can seamlessly adapt to the CPU module (such as GFD233A103) and I/O module (such as SPSED01, DO810) of Symphony Plus control system. High speed data exchange is achieved through the system backplane bus, with a data transmission rate of up to 100Mbps. The circuit board reserves 2 expansion interfaces, supporting the connection of dedicated function sub cards (such as communication expansion cards, signal acquisition expansion cards), which can expand the number of channels or add communication protocol support according to actual control needs, improving the flexibility and applicability of system configuration, and reducing hardware replacement costs caused by functional upgrades.

2.5 Comprehensive fault diagnosis and status monitoring

The circuit board is equipped with a comprehensive self diagnostic circuit, which can monitor the working status, power supply voltage stability, input and output signal integrity, and bus communication link status of core components (microprocessor, FPGA, ADC/DAC) in real time. When a fault is detected, a fault code is immediately output through the status indicator light and communication interface. The fault information includes the type of fault (such as power abnormality, ADC conversion fault, communication interruption), the time of fault occurrence, and the associated channel number, making it easy for operation and maintenance personnel to quickly locate the fault point. At the same time, the circuit board supports reading real-time operating parameters (such as temperature, power supply voltage, channel signal values) through the upper configuration software, providing data support for preventive maintenance.

Core technical parameters

Core processor

300MHz embedded microprocessor+Xilinx industrial grade FPGA

Analog input channel

8 channels, supporting 4-20mA/0-10V/thermocouple/thermistor signals

Analog output channel

4-channel, 4-20mA/0-10V configurable, output accuracy of 0.05% FS

Digital I/O channel

16 channels (8 in and 8 out), supporting DI/DO/PWM/pulse capture

ADC/DAC specifications

16 bit ADC (sampling rate 500kHz), 16 bit DAC

Signal conditioning accuracy

±0.1%FS

Isolation voltage

Input/output channel ≥ 2500V AC, power supply ≥ 1500V AC

communication interface

ABB system backplane bus, 1 RS485 (supporting Modbus RTU)

power supply voltage

24V DC ± 20%, power consumption ≤ 15W

Operating Temperature

-20℃~65℃

relative humidity

5%~95%, no condensation

Overall dimensions

180mm x 120mm x 25mm (length x width x thickness)

certification standard

IEC 61131-2,UL 508,ATEX Zone 2,SIL 2

Typical application scenarios

4.1 Steam Turbine Control System in the Power Industry

In the steam turbine control system of thermal power plants and nuclear power plants, the UFC765AE102 circuit board serves as the core signal processing unit of the DEH (Digital Electro Hydraulic Control System), responsible for collecting key parameters such as turbine speed, shaft vibration, tile temperature, and steam pressure. After PID calculation and logical judgment through built-in algorithms, it outputs control signals to drive the action of the electro-hydraulic servo valve, achieving precise adjustment of turbine speed and load. Its high-precision signal processing capability ensures a speed control accuracy of ± 1rpm, and its anti-interference design can resist electromagnetic interference generated by high-voltage equipment in power plants, ensuring stable operation of the steam turbine. When faults such as excessive speed and abnormal vibration occur, the circuit board can quickly execute interlocking protection logic, trigger emergency stop commands, and avoid equipment damage.

4.2 Petrochemical Reactor Control

In the control system of large-scale chemical reaction vessels, this circuit board can centrally process multidimensional signals such as temperature, pressure, liquid level, and stirring speed inside the reaction vessel. The temperature signal collected by the thermocouple and the current signal of the pressure transmitter are converted into digital signals through the signal conditioning unit. After FPGA logic operation, control instructions are output to adjust the power of the heating device, the opening of the feed valve, and the speed of the stirring motor, ensuring that the reaction process parameters are stable within the process requirements. Its isolation protection design can effectively avoid the impact of corrosive gases and electromagnetic interference on circuits in chemical sites. The fault diagnosis function can timely detect problems such as sensor disconnection and actuator failure, providing a guarantee for the safe and controllable reaction process.

4.3 Speed Control System for Steel Rolling Mill in Metallurgical Industry

In the speed control system of the rolling mill on the continuous rolling production line of the steel plant, the UFC765AE102 circuit board is responsible for the core tasks of speed signal acquisition and control command output. By collecting the speed pulse signals of the rolling mill motor and the rolling force sensor signals, the circuit board quickly calculates and outputs PWM control signals to adjust the frequency of the frequency converter, achieving closed-loop control of the rolling mill speed and ensuring uniform thickness of the steel during rolling. Its high-speed computing capability can meet the control requirements of high-speed steel rolling production lines, and the overcurrent protection function can timely cut off the control signal when the motor is overloaded, protecting the frequency converter and motor from damage. At the same time, the high-speed communication capability between the circuit board and the main controller of the production line enables collaborative control of multiple rolling mills, improving production efficiency.

4.4 Soft start control for large motors

In the soft start control system of large high-voltage motors in industries such as mining and water conservancy, this circuit board serves as the core control unit of the soft starter, responsible for collecting the current, voltage, and speed signals of the motor, and controlling the conduction angle of the thyristor through the built-in soft start algorithm to achieve smooth starting of the motor and avoid the impact of excessive starting current on the power grid and motor. During the start-up process, the circuit board monitors the motor's operating parameters in real time. When overcurrent, overvoltage, or phase loss faults occur, the protection mechanism is immediately triggered, the thyristor trigger signal is cut off, and an alarm is issued. Its wide voltage input and anti-interference design can adapt to harsh outdoor working environments such as mines and water conservancy, ensuring the reliability of motor start-up and operation

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-