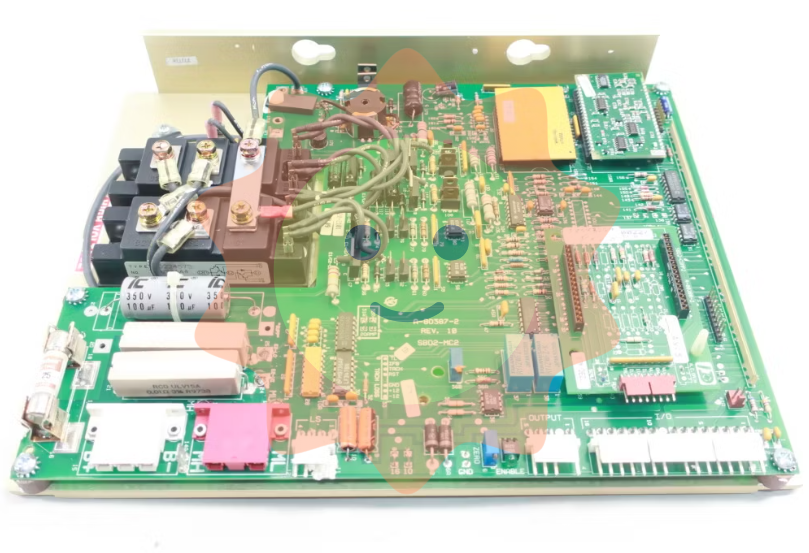

Kollmorgen 3EF-50 - Line Filter

The Kollmorgen 3EF-50 is a robust and high-performance automation solution designed specifically to meet the demanding requirements of the power industry, petrochemical plants, and general automation applications. Engineered for durability and precision, the 3EF-50 stands out with its exceptional input/output capacity, resilient construction, and optimized performance metrics, making it an indispensable component in critical industrial environments. At its core, the Kollmorgen 3EF-50 boasts a high input voltage tolerance and scalable output capabilities that enable it to handle complex control tasks with ease. Its input channels support a wide range of signal types, ensuring compatibility with various sensors and control devices commonly found in power generation and petrochemical processes. The output modules deliver precise actuation signals with minimal latency, crucial for maintaining process stability and operational safety.

The 3EF-50’s ruggedized housing and advanced thermal management ensure reliable operation even under harsh environmental conditions, including extreme temperatures and exposure to corrosive substances often encountered in petrochemical plants. In terms of performance, the 3EF-50 achieves rapid response times and high cycle durability, allowing it to sustain continuous operation with minimal downtime. Its integrated diagnostics and fault-tolerant design enhance system reliability, reducing maintenance costs and improving overall plant efficiency. This makes the Kollmorgen 3EF-50 ideal for applications such as turbine control in power plants, process automation in refineries, and complex assembly line management within general automation sectors. When comparing the Kollmorgen 3EF-50 to other models within the Kollmorgen automation portfolio, its unique advantages become clear. For instance, while the Kollmorgen M256F-0S101-7000-0 excels in high-speed motion control and the Kollmorgen PRD-MZ39000I-00 offers specialized power monitoring capabilities, the 3EF-50 integrates robust I/O handling with exceptional environmental resistance not always present in these models.

The Kollmorgen IC11030A1TSC1 and MT506B2-R1C1 provide complementary functionalities in servo drive and motor control, but neither matches the 3EF-50’s tailored design for heavy industrial automation environments. Likewise, the Kollmorgen NEAT-310M and S30101-NA-024 series are well-regarded for their modularity and ease of integration, yet the 3EF-50 offers a superior combination of ruggedness and precise control, critical in power and petrochemical applications. Alongside the Kollmorgen 3EF-50, we also offer the Kollmorgen PRD-0051AMPE-Y0 and Kollmorgen 610 models, which support expanded control architectures and provide additional power management features. The Kollmorgen SR6-6SMx7 and DIGIFAS 7202-L2/DP units further enhance system capabilities for applications requiring advanced feedback and safety integration. For specialized drive requirements, the Kollmorgen AKM11B-ASSNR-02 and AKD-P00606-NAEC-0000 represent powerful options for motor control that complement the 3EF-50’s comprehensive automation functionality.

Additionally, the Kollmorgen BDS4A-210J-WO and MTC1504AE-HMC10-1 units offer enhanced sensor interfaces and signal conditioning, rounding out a complete solution portfolio. The application of the 3EF-50 in the power industry is particularly notable for its ability to manage critical control loops in turbine governor systems, ensuring stable and efficient electricity generation. In petrochemical facilities, its robust design maintains process integrity where hazardous conditions and volatile materials demand continuous, fail-safe operation. Within general automation, the 3EF-50’s flexibility and integration capabilities streamline complex manufacturing workflows, boosting productivity and reducing operational risk. As part of the broader Kollmorgen automation products lineup, the 3EF-50 exemplifies the brand’s commitment to precision, durability, and innovation.

By integrating the 3EF-50 with complementary models such as the Kollmorgen PRD-KD30030z-53 and SR03000-Y015, users can build scalable, adaptable systems tailored to their unique industrial challenges. Whether optimizing plant control in a power station, enhancing safety in a petrochemical process, or automating intricate production lines, the Kollmorgen 3EF-50 delivers unmatched reliability and performance. In summary, the Kollmorgen 3EF-50 is a top-tier automation component engineered for the toughest industrial environments. Its superior input/output capacity, rugged design, and precise control make it the ideal choice for power industry, petrochemical, and general automation applications. Supported by a comprehensive ecosystem of Kollmorgen products, the 3EF-50 ensures seamless integration and exceptional operational efficiency, embodying the pinnacle of Kollmorgen automation products.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-