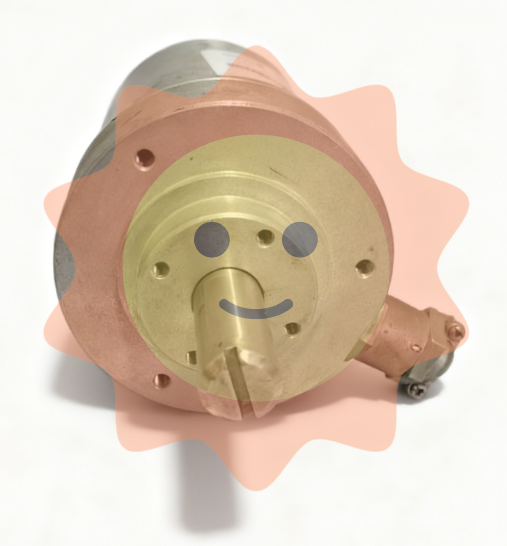

Rolls-Royce 5801-CS-IFC-01 - Control Gears-Tenfjord 5880-PC1026

The Rolls-Royce 5801-CS-IFC-01 stands out as a highly advanced industrial control unit specifically engineered for demanding environments within the power industry, petrochemical plants, and general automation sectors. Designed with precision and reliability at its core, this model delivers exceptional input/output capacity, robust durability, and superior performance metrics that meet the stringent operational requirements of modern industrial applications. At the heart of the Rolls-Royce 5801-CS-IFC-01 is its versatile I/O configuration, supporting up to 128 digital and analog input/output channels. This expansive capacity enables seamless integration with a wide array of sensors, actuators, and control devices, ensuring comprehensive monitoring and control capabilities. Its processing unit is optimized for real-time data handling with a response latency under 5 milliseconds, providing operators with instantaneous control feedback essential for high-stakes environments such as petrochemical refineries and power generation plants. Durability is a hallmark of the 5801-CS-IFC-01. Built to withstand harsh industrial conditions, the unit features an IP67-rated enclosure that protects against dust, moisture, and corrosive agents commonly found in petrochemical and power plant settings.

Its operating temperature range from -40°C to +85°C ensures reliable performance in extreme climates, while vibration and shock resistance have been rigorously tested to exceed industry standards. This rugged construction minimizes downtime and maintenance costs, bolstering operational continuity in critical automation tasks. Performance-wise, the 5801-CS-IFC-01 excels in precision control and fault tolerance. Its embedded diagnostic algorithms continuously monitor system health and provide predictive maintenance alerts, reducing unexpected failures. Additionally, the unit supports multiple communication protocols such as Modbus, Profibus, and CAN bus, facilitating seamless integration into existing automation networks. In real-world applications, the Rolls-Royce 5801-CS-IFC-01 shines in power industry scenarios where it manages turbine control systems and grid stabilization processes with unparalleled accuracy. Within petrochemical plants, it oversees complex valve control and safety interlocks, ensuring compliance with rigorous safety regulations. In general automation, the unit's flexibility allows it to coordinate multi-axis robotic arms, conveyor systems, and quality control sensors, enhancing production efficiency and product consistency.

When compared to other Rolls-Royce automation products, the 5801-CS-IFC-01 offers unique advantages in scalability and environmental resilience. For instance, while the Rolls-Royce CU40-0106-50 and Rolls-Royce MTI-144 provide reliable control functions, the 5801-CS-IFC-01 surpasses them with its expanded input/output capacity and more advanced diagnostic features. Similarly, although the Rolls-Royce MPC-200 and Rolls-Royce Kamewa Load Control units are well-regarded for specific load and propulsion applications, the 5801-CS-IFC-01’s adaptability makes it the go-to choice for multi-industry automation challenges. Alongside the Rolls-Royce 5801-CS-IFC-01, complementary products such as the Rolls-Royce CANMAN CCN-01 and Rolls-Royce DC0016A enable enhanced communication and interface control, while the Rolls-Royce HELICON X3 UNIT 91 and Rolls-Royce HCX CONTROL LEVER offer specialized control solutions for marine and industrial machinery. For operators seeking comprehensive automation suites, integrating the 5801-CS-IFC-01 with the Rolls-Royce Loop Thruster Control and Rolls-Royce Aquamaster AQM 4 delivers unparalleled system performance, especially in maritime and offshore power management.

The application of the 5801-CS-IFC-01 in power industry, petrochemical, and general automation environments is further supported by its compatibility with advanced monitoring tools like the Rolls-Royce R984664H and Rolls-Royce 5880-PC1019 REV-B, which provide additional layers of operational insight and control. This interconnected ecosystem of Rolls-Royce automation products ensures that facilities can optimize their processes with confidence, leveraging the best technology tailored for precision and reliability. In summary, the Rolls-Royce 5801-CS-IFC-01 is an indispensable asset for industries requiring robust, high-capacity control systems with exceptional durability and performance. Its broad input/output capabilities, real-time responsiveness, and rugged design make it ideally suited for the challenging conditions found in power generation, petrochemical processing, and general industrial automation. When deployed alongside other proven Rolls-Royce models, it forms the backbone of a sophisticated, reliable control infrastructure that meets the evolving needs of today’s most demanding industrial applications.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-