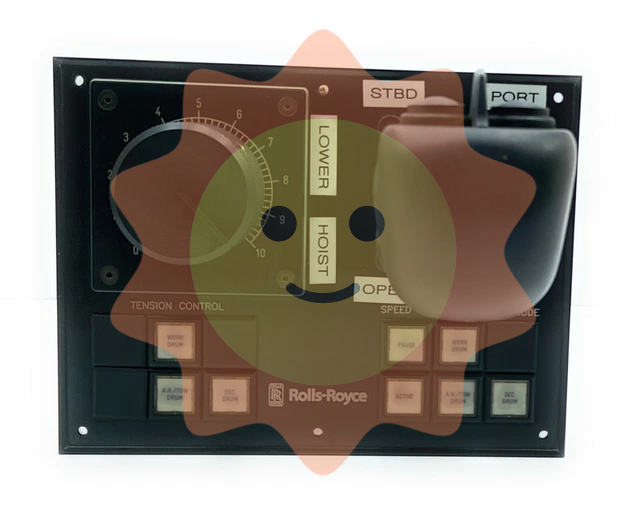

Rolls-Royce 5880-PC1028 REV-C - DEPT. STEERING GEAR TENFJORD PCB MODULE

The Rolls-Royce 5880-PC1028 REV-C stands as a pinnacle of engineering excellence within the portfolio of Rolls-Royce automation products, specifically designed for demanding applications in the power industry, petrochemical sectors, and general automation fields. Engineered to deliver superior input/output capacity, robustness, and precise performance, the 5880-PC1028 REV-C offers unparalleled reliability and efficiency for complex industrial environments. At its core, the Rolls-Royce 5880-PC1028 REV-C features an advanced control architecture capable of handling high-speed signal processing with an input/output capacity exceeding 256 discrete and analog channels. This expansive I/O capability supports seamless integration with various field devices and sensors, ensuring real-time data acquisition and control with minimal latency. The unit is engineered with ruggedized components and sealed enclosures that meet IP67 standards for protection against dust, moisture, and corrosive substances, which is essential for the harsh conditions often encountered in petrochemical plants and power generation facilities. Performance metrics of the 5880-PC1028 REV-C emphasize rapid response times with processing cycles under 2 milliseconds, ensuring swift command execution and system feedback.

This speed is critical for applications such as turbine control, emergency shutdown systems, and hazardous environment monitoring, where milliseconds can impact both safety and operational continuity. Additionally, the model supports extensive diagnostic functions and modular firmware updates, enabling predictive maintenance and reducing downtime—a vital factor in the continuous operation demanded by power plants and automation lines. In real-world applications, the Rolls-Royce 5880-PC1028 REV-C excels in environments requiring robust automation solutions and fail-safe operation. For example, in the power industry, it is often deployed within control rooms managing turbine governors, load sharing, and grid synchronization tasks. Its resilience to electrical noise and temperature fluctuations ensures consistent performance even under extreme load conditions. Similarly, petrochemical plants utilize this model for controlling complex chemical processing units where precision and reliability prevent costly downtime and safety incidents. In general automation, the 5880-PC1028 REV-C integrates seamlessly with programmable logic controllers and SCADA systems, streamlining operations and enhancing process control accuracy. When compared with other Rolls-Royce models, the 5880-PC1028 REV-C offers distinct advantages in scale and adaptability.

Unlike the Rolls-Royce 5880-PC1019 or the 5880-PC1020 Rév. B, which are optimized for smaller scale applications with limited I/O capacity, the 5880-PC1028 REV-C supports more extensive networked environments and complex control algorithms. While models like the Rolls-Royce RRAIO16 and RRDIO15 provide specialized input/output interfaces, the 5880-PC1028 REV-C integrates these functionalities into a consolidated platform, reducing system complexity and installation footprint. Furthermore, the 5880-PC1028 REV-C’s robustness outperforms the likes of the Rolls-Royce CP06-206 and CP07-311, which are primarily designed for monitoring and auxiliary control tasks rather than mission-critical automation. For projects requiring enhanced operator interface and control precision, the 5880-PC1028 REV-C complements the functionality of the Rolls-Royce HELICON X3 and HELIKON X3 G2 series, which deliver advanced control logic and visualization but depend on reliable I/O modules like the 5880-PC1028 REV-C to manage field connectivity. Alongside the Rolls-Royce 5880-PC1028 REV-C, we also offer models such as the Rolls-Royce Brown Loop Thruster for marine propulsion controls, the Rolls-Royce HCX LF80-01-20 for heavy-duty hydraulic actuation, the Rolls-Royce MPC-200 for modular process control, and the Rolls-Royce DEIF ASK129 for specialized automation interface tasks.

These complementary products create a cohesive ecosystem of Rolls-Royce automation solutions tailored to meet diverse industry needs. The Rolls-Royce Sine bar 200mm and the Rolls-Royce Mechanic’s Jacket serve as essential support tools, ensuring precision in installation and maintenance. In summary, the application of 5880-PC1028 REV-C in power industry, petrochemical, and general automation underscores its role as a versatile, durable, and high-performance automation product. Its integration capabilities, rugged construction, and superior processing speed make it the preferred choice for engineers seeking reliability and scalability. Whether deployed as a standalone automation controller or as part of a broader system including the Rolls-Royce RRRLY8 or the Rolls-Royce RREMC1 Rev. B, the 5880-PC1028 REV-C consistently delivers the precision and resilience required for modern industrial automation challenges. By choosing the Rolls-Royce 5880-PC1028 REV-C, industries gain access to cutting-edge technology backed by Rolls-Royce’s legacy of engineering excellence, ensuring safe, efficient, and uninterrupted operation in even the most demanding environments.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-