Product model: 6AV2124-2DC01-0AX0

Series: Siemens SIMATIC HMI, specifically SIMATIC HMI KTP400 COMFORT Comfort Panel

Core positioning: A human-machine interaction interface that integrates touch and button operations, suitable for process control and data monitoring in industrial automation scenarios. The document version date is June 23, 2014, and there may be subsequent modifications to the content.

Siemens 6AV2124-2DC01-0AX0 Comfort Panel

Product basic information

Product model: 6AV2124-2DC01-0AX0

Series: Siemens SIMATIC HMI, specifically SIMATIC HMI KTP400 COMFORT Comfort Panel

Core positioning: A human-machine interaction interface that integrates touch and button operations, suitable for process control and data monitoring in industrial automation scenarios. The document version date is June 23, 2014, and there may be subsequent modifications to the content.

Core hardware specifications

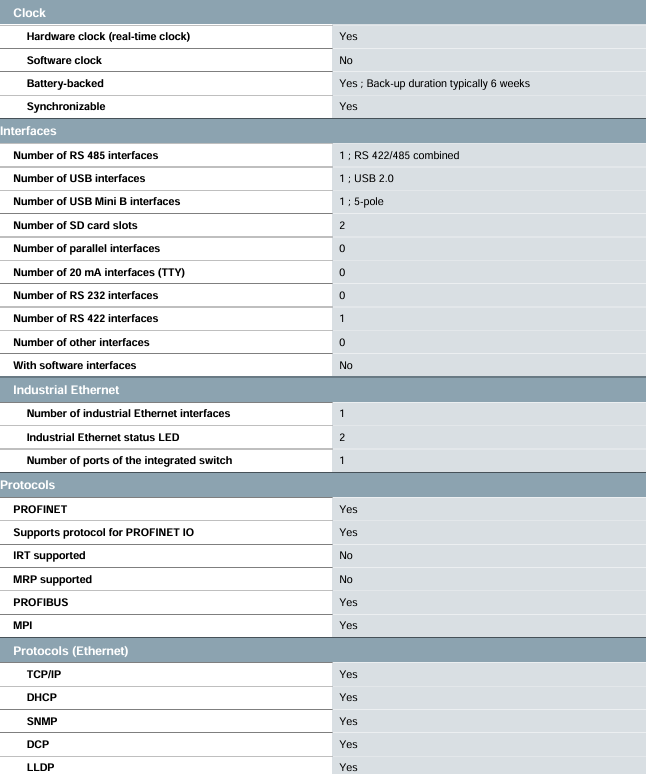

(1) Display and operation configuration

Category parameter details

Display design: 4.3-inch widescreen TFT display screen, with a width of 95mm and a height of 53.8mm

Display performance of 16777216 colors (16 million colors), resolution of 480 × 272 pixels

Backlight characteristics MTBF (at 25 ° C) 80000 hours, supporting 0-100% brightness adjustment

Operation mode touch operation: supports touch screen function;

Key operation: 4 function keys with LED indicator lights, no system key;

Input method: Supports on-screen virtual numeric/alphabetical keyboard

Expand control with 4 direct buttons (F1 FX) for S7 input/output, 32 touch direct buttons for S7 input/output, and 4 DP direct LEDs (as S7 output I/O)

(2) Installation and Dimensions

Installation flexibility: Supports vertical and horizontal installation, with vertical installation as the default method and a maximum allowable tilt angle of 35 ° (without external ventilation)

Protection level: IP65 on the front (compliant with Type 4/4x protection standards), IP20 on the back

Size and weight:

-Front dimensions: width 140mm x height 116mm

-Installation incision: width 123mm x height 99mm

-Equipment depth: 49mm

-Weight: 0.6kg without packaging, 0.7kg with packaging included

(3) Power supply and power consumption

Power supply requirements: DC 24V, allowable range 19.2V-28.8V

Current characteristics: rated current 0.13A, surge current 0.5A ² · s

Power consumption: typical value of 3.1W

(4) Processor and Storage

Processor: ARM architecture (non-X86)

Storage configuration: including Flash and RAM, user available memory 4MB; supports 2 SD card slots, 1 USB 2.0 interface, 1 5-pole USB Mini B interface, expandable storage

Interface and Communication Capability

(1) Physical interface

Number and specifications of interface types

One industrial Ethernet interface with two status LEDs, integrated with one port switch

1 RS 422/485 interface (combination interface), including 1 RS 422 interface

USB interface: 1 USB 2.0, 1 5-pole USB Mini B

2 SD card slots

Other interfaces have no parallel interface, 20mA TTY interface, or RS 232 interface

(2) Support agreement

Industrial bus protocols: PROFINET (supports PROFINET IO, does not support IRT and MRP), PROFIBUS DP, MPI

Ethernet protocols: TCP/IP, DHCP, SNMP, DCP, LLDP

Other protocols: MODBUS, EtherNet/IP (supporting Allen Bradley device communication)

Web related: Supports HTTP, HTML, CSS, JavaScript, but does not support HTTPS, XML, Active X, Java VM

Software and Function Configuration

(1) System and Configuration

Operating System: Windows CE 6.0

Software configuration: Requires configuration through WinCC Comfort (TIA Portal V11 and above), WinCC Advanced/Professional (TIA Portal V11 and above), does not support STEP 7 Basic/Professional, WinCC flexible series

Clock function: Hardware real-time clock (with battery backup, typical backup duration of 6 weeks), supports synchronization, no software clock

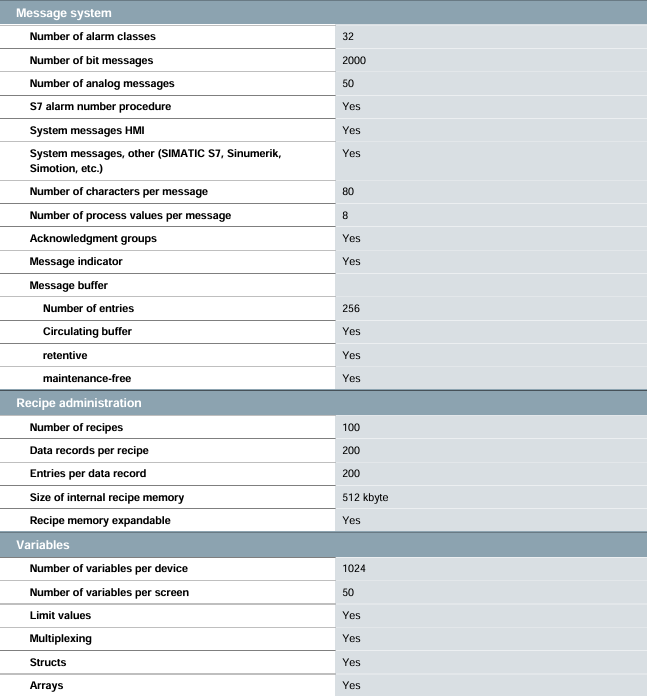

(2) Core functions

Specific abilities of functional categories

Supports 32 online/running languages and 32 project languages (including simplified and complex Chinese, English, German, French, Japanese, etc.)

32 alarm categories, 2000 bit messages, and 50 simulated messages for alarms and messages; Support S7 alarm number, HMI and other system messages; 256 message buffers (loop, hold, maintenance free), each containing 80 characters and 8 process values, supporting confirmation groups and message indications

100 formulas are managed, with 200 data records for each formula and 200 entries for each data record; Internal recipe memory 512KB, supports expansion

Variable management includes 1024 variables for a single device and 50 variables for a single screen; Supports limit values, multiplexing, structures, and arrays

500 configurable screens for images and objects, with 50 objects per screen (text boxes, I/O fields, switches, buttons, etc.) and 5 complex objects (alarm views, trend views, etc.); Support global screen, configurable startup screen, and screen selection through PLC

10 data archives, with 10000 entries per archive; Support message archiving and process value archiving, with archiving methods including sequential archiving and short-term archiving; Can be stored on a memory card USB、 Ethernet, supports CSV, TXT, RDB formats

50 user groups, 50 users, and 32 user permissions for security management; Support password import/export SIMATIC Logon

Additional tools support screen cleaning, touch calibration, backup/restore (including automatic backup), simulation, device switching, and incremental transfer; Can connect to printers (print alarms, shift records, etc.) and network cameras

Environment and Certification

(1) Environmental adaptability

Temperature range:

-Operating temperature: Vertical installation 0-50 ° C, maximum tilt angle 0-40 ° C; vertical screen installation 0-40 ° C, maximum tilt angle 0-35 ° C

-Storage/transportation temperature: -20-60 ° C

Humidity: Maximum relative humidity of 90% (without condensation)

Installation angle: Vertical installation is the main method, with a maximum tilt angle of 35 ° (without external ventilation)

(2) Certification and Compliance

Basic certifications: CE, KC, cULus, RCM (formerly C-TICK)

Maritime certification: GL, ABS, BV, DNV, LRS, NK, not supported by PRS

Hazardous Area Use: Supports ATEX Zone 2/22, IECEx Zone 2/22 (soon to be available) cULus Class I Zone 2(Division 2)、FM Class I Division 2, Not supporting cULus Class I Zone 1

EMC compliance: Complies with EN 55 011 radio interference emission standard (limit level A, non level B)

Equipment compatibility

Support coupling communication with various industrial equipment, including Siemens S7-1200/1500/200/300/400, LOGO! 、 Win AC、SINUMERIK, And third-party devices such as Allen Bradley(EtherNet/IP、DF1)、Mitsubishi(MC TCP/IP、FX)、OMRON(LINK/Multilink, Not supporting FINS TCP, Modicon (Modbus TCP/IP, Modbus); Support OPC UA client (non server).

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-