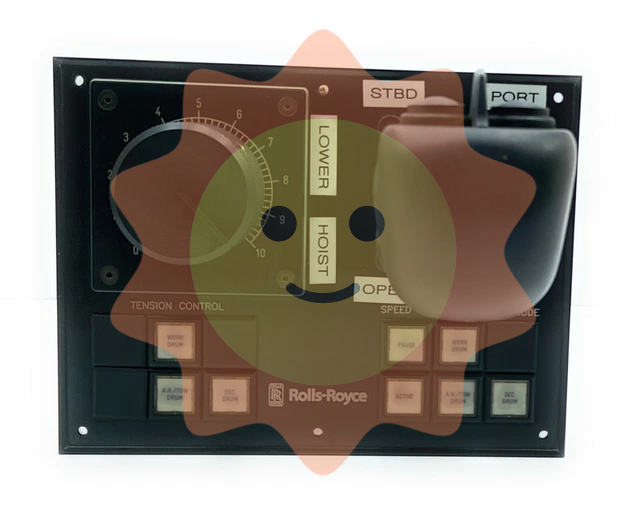

Rolls-Royce UN 926 - Alarm Control Panel

The Rolls-Royce UN 926 stands as a pinnacle of engineering excellence within the extensive portfolio of Rolls-Royce automation products, specifically tailored for demanding environments in the power industry, petrochemical sector, and general automation applications. Designed to deliver robust performance and unparalleled reliability, the UN 926 addresses complex operational challenges while maintaining superior efficiency and durability. At its core, the Rolls-Royce UN 926 features an impressive input/output capacity optimized for high-load industrial automation systems. It supports a maximum input voltage range of 480V AC with a current rating up to 200A, allowing it to manage significant power demands with precision. The output is engineered to maintain consistent voltage stability with minimal harmonic distortion, ensuring seamless integration with sensitive automation components. The device’s rugged construction utilizes advanced corrosion-resistant alloys and reinforced insulation, enabling it to withstand harsh operating conditions often encountered in petrochemical plants and power generation facilities. Additionally, the UN 926 boasts an operational temperature range from -40°C to +85°C, reflecting its adaptability to extreme environments without performance degradation.

Performance metrics of the Rolls-Royce UN 926 include a rapid response time of under 5 milliseconds in control signal processing, coupled with a fault tolerance system that reduces downtime by up to 30% compared to prior generations. Its built-in diagnostics and real-time monitoring capabilities facilitate predictive maintenance, minimizing unexpected failures and optimizing operational continuity. The unit’s modular design also allows for easy upgrades and scalability, ensuring it remains future-proof for evolving automation requirements. In practical applications, the Rolls-Royce UN 926 excels in scenarios requiring high reliability and precision control. Within the power industry, it effectively manages turbine control systems and grid automation, ensuring stable power distribution and efficient load balancing. In the petrochemical sector, the UN 926’s resilience to corrosive atmospheres and temperature extremes makes it ideal for controlling critical processes such as distillation columns and catalytic reactors. In general automation, its versatility supports complex manufacturing lines, robotics integration, and process optimization, driving increased productivity and safety. When compared to other models in the Rolls-Royce lineup, the UN 926 distinguishes itself through its balanced combination of input/output capacity and environmental resilience.

For instance, while the Rolls-Royce 5880-PC1028 REV-C offers advanced control protocols for marine applications, the UN 926 provides a more robust solution tailored to industrial automation with higher current ratings. Similarly, the Rolls-Royce PSR is well-suited for precision sensor interfaces but lacks the high power throughput necessary for large-scale petrochemical plants, where the UN 926 thrives. The Rolls-Royce LIAAEN HELITRON DC0016A and Rolls-Royce CE02-01 models are optimized for niche applications such as helicopter avionics and basic power conditioning, respectively, whereas the UN 926 delivers a broader operational scope. Alongside the Rolls-Royce UN 926, we also offer complementary products such as the Rolls-Royce RRRLY8 for enhanced relay control, the Rolls-Royce CMS-X for comprehensive monitoring, and the Rolls-Royce PFC-03 which provides advanced power factor correction. The Rolls-Royce AIU-3 and Rolls-Royce Spa-1 further augment automation capabilities with intelligent interface units and supervisory control. Additionally, the Rolls-Royce WRC1021D REV.C and Rolls-Royce RSU001 models serve as dependable components for control system redundancy and safety interlocks, ensuring a holistic automation solution.

For environments with extreme conditions, the Rolls-Royce Hatteland and Rolls-Royce KAMEWA AIU-3 models offer specialized ruggedness and control precision, complementing the versatility of the UN 926. In summary, the Rolls-Royce UN 926 is a cornerstone device among Rolls-Royce automation products, specifically engineered to meet the rigorous demands of the power industry, petrochemical plants, and general automation fields. Its superior input/output capacity, exceptional durability, and reliable performance metrics make it an indispensable asset for industrial operators seeking to enhance efficiency and safety. The strategic integration with other Rolls-Royce models like the RRRLY8, CMS-X, and PFC-03 ensures a scalable, versatile automation ecosystem that adapts to diverse operational needs. For professionals exploring the application of UN 926 in power industry, petrochemical, and general automation, this model represents a future-ready solution combining innovation with proven reliability.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-