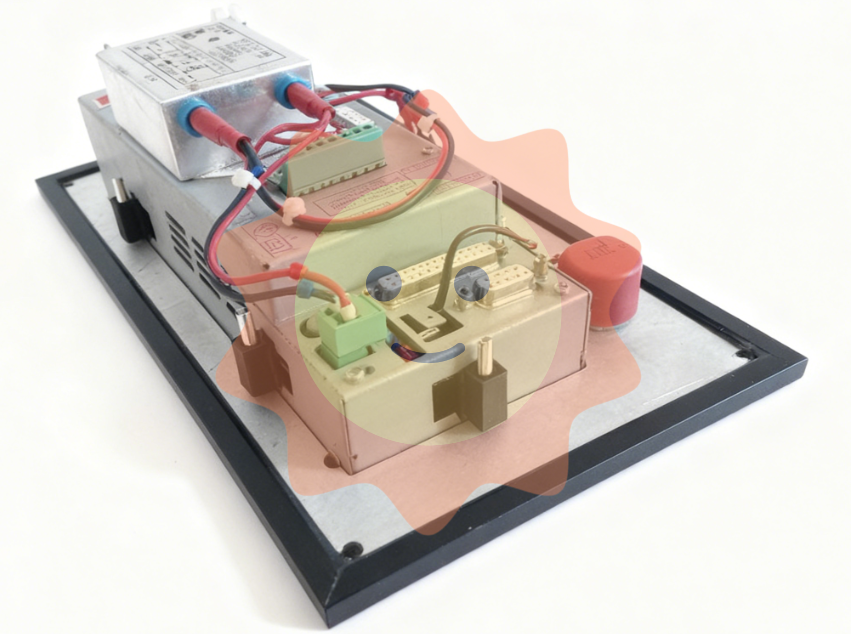

Rolls-Royce MPC200 - Aquamaster-Rauma PCB Module Oy Ab. Version 1.13KC

The Rolls-Royce MPC200 stands as a pinnacle of innovation within the realm of industrial automation, specifically engineered to meet the demanding requirements of the power industry, petrochemical sectors, and general automation environments. Renowned for its robust design, exceptional input/output capacity, and unwavering durability, the MPC200 ensures seamless integration and superior operational performance under the most challenging conditions. At the core of the Rolls-Royce MPC200 is its high-capacity I/O system, designed to handle complex signal processing with remarkable precision. It supports a wide voltage range, accommodating both analog and digital inputs and outputs, which enables it to interface effortlessly with diverse industrial machinery and control systems. This flexibility is vital for applications where precise control and rapid response times are critical, such as in power generation plants or petrochemical processing units. The MPC200's rugged construction affords it excellent resistance to vibration, temperature fluctuations, and corrosive environments, ensuring reliability and longevity even in harsh industrial settings. Performance metrics underscore its capacity for continuous operation with minimal downtime, bolstered by advanced diagnostics and fault-tolerant features that maintain system integrity and reduce maintenance costs.

In real-world scenarios, the Rolls-Royce MPC200 excels in optimizing automation workflows by providing precise control and monitoring capabilities. In the power industry, it manages turbine control systems with high accuracy, ensuring efficient energy output and operational safety. Within petrochemical plants, the MPC200 facilitates complex process control, managing the intricate balance of chemical reactions and fluid dynamics essential for product quality and safety compliance. Its adaptability also shines through in general automation applications, where it integrates with supervisory control and data acquisition (SCADA) systems to streamline factory operations, enhance productivity, and reduce human error. When compared to other Rolls-Royce automation products, the MPC200 offers a unique blend of high input/output density and robust environmental protection. For example, unlike the Rolls-Royce FMV 25B or the Rolls-Royce M44-R3, which are optimized for more specific control functions, the MPC200 delivers broader compatibility and enhanced scalability, making it suitable for a wider range of industrial applications.

Additionally, the MPC200 surpasses models such as the Rolls-Royce CanMan Slio 01 and Rolls-Royce CE01-02 in terms of processing speed and fault tolerance, providing operators with faster response times and greater system resilience. Alongside the Rolls-Royce MPC200, complementary models such as the Rolls-Royce HCX-TT and Rolls-Royce POSCON V.3 offer specialized thruster control solutions, enhancing vessel maneuverability in marine-related automation scenarios. The Rolls-Royce Brunvoll Lazo and the Rolls-Royce Loop Thruster Control systems further extend the capabilities of automation in navigation and propulsion control, highlighting Rolls-Royce’s comprehensive approach to industrial and marine automation. The Rolls-Royce MPCF1-10.4" serves as an ideal human-machine interface (HMI) companion to the MPC200, providing operators with intuitive visualization and control panels that simplify complex process management. For applications demanding enhanced monitoring and diagnostic capabilities, the Rolls-Royce Syst 6011 95371123 and Rolls-Royce 5880-PC1020 Rev.B modules offer advanced data acquisition and processing features that integrate seamlessly with the MPC200 platform.

Incorporating the Rolls-Royce MPC200 into your automation infrastructure means embracing a solution designed with reliability and versatility in mind. Its proven track record in the power industry, petrochemical applications, and general automation underscores its capability to deliver consistent performance while minimizing operational risks. The MPC200’s compatibility with a broad range of Rolls-Royce automation products ensures that it fits neatly into existing systems, allowing for scalable upgrades and system enhancements without significant overhauls. For organizations seeking to optimize their control systems, the application of MPC200 in power industry, petrochemical, and general automation presents a strategic advantage. Its combination of rugged design, extensive I/O support, and high-performance processing makes it a trusted choice among engineers and operators worldwide.

By integrating the Rolls-Royce MPC200 alongside related models such as the Rolls-Royce H1127.0101 and Rolls-Royce CE02-01, businesses benefit from a cohesive automation ecosystem that supports operational excellence and future growth. In summary, the Rolls-Royce MPC200 is a cornerstone of advanced industrial automation. Its unique technical features, broad application scope, and synergy with other Rolls-Royce automation products position it as an indispensable asset for industries demanding precision, durability, and reliability. Whether managing power generation, optimizing petrochemical processes, or automating complex production lines, the MPC200 delivers unmatched control and efficiency, embodying Rolls-Royce’s commitment to engineering excellence and innovation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-