Rolls-Royce Aquamaster-Rauma mpc-200 - Per Express

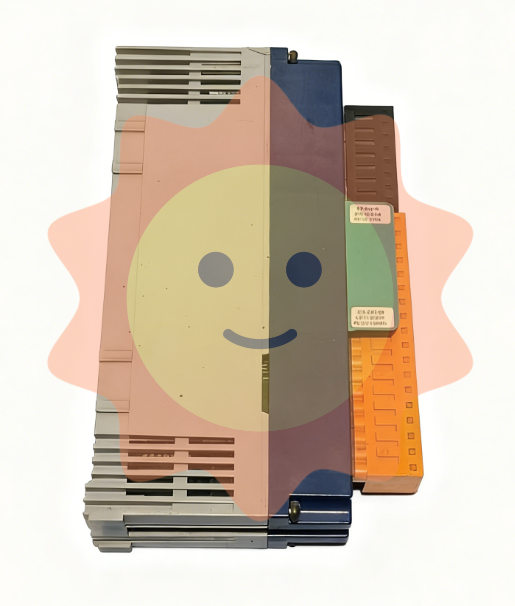

The Rolls-Royce Aquamaster-Rauma mpc-200 stands as a pinnacle of advanced automation technology, specifically engineered to meet the demanding requirements of the power industry, petrochemical sectors, and general automation applications. Renowned for its robust design and exceptional performance, the Aquamaster-Rauma mpc-200 integrates powerful input/output capabilities with unparalleled durability, making it a reliable choice for complex industrial environments. At its core, the Rolls-Royce Aquamaster-Rauma mpc-200 offers an extensive I/O capacity that enables seamless control and monitoring of multiple process variables simultaneously. Featuring a modular architecture, the system supports a wide range of digital and analog inputs and outputs, allowing for high configurability tailored to specific operational needs. The device excels in handling high-frequency data processing, ensuring rapid response times critical for real-time applications in automation and control. Its rugged construction is designed to withstand harsh environmental conditions, including extreme temperatures, vibration, and exposure to corrosive substances commonly found in petrochemical plants and power generation facilities. This durability ensures long-term operational stability and reduced downtime, significantly enhancing overall plant efficiency.

Performance metrics of the Aquamaster-Rauma mpc-200 are impressive, with its high-speed processing unit capable of executing complex control algorithms with minimal latency. The system supports advanced communication protocols, which facilitate seamless integration with existing plant infrastructure and supervisory control and data acquisition (SCADA) systems. This interoperability is vital in multi-vendor environments where flexibility and scalability are prioritized. In real-world applications, the Rolls-Royce Aquamaster-Rauma mpc-200 excels in controlling critical processes such as turbine management in power plants, chemical reactor automation in petrochemical industries, and general automation tasks ranging from assembly line control to energy management systems. Its precision and reliability make it an indispensable component in scenarios where safety and accuracy are paramount. For instance, in the power industry, the mpc-200 ensures optimal turbine performance by continuously adjusting operational parameters based on real-time sensor input, thereby maximizing efficiency and minimizing emissions.

Similarly, in the petrochemical sector, it manages complex reaction sequences and safety interlocks with a high degree of accuracy, reducing the risk of operational hazards. When compared to other Rolls-Royce automation products, the Aquamaster-Rauma mpc-200 distinguishes itself through its enhanced modularity and superior environmental resistance. Unlike models such as the Rolls-Royce MPC-200/MPC220, which offer reliable automation but with less extensive I/O flexibility, the mpc-200 provides a broader array of connectivity options and faster processing speeds. While the Rolls-Royce CanMan SLIO 02 and CanMan CCN01 are excellent for localized control tasks, the Aquamaster-Rauma mpc-200 is engineered for full-scale plant automation, making it ideal for large, integrated systems. Additionally, the mpc-200 complements other Rolls-Royce solutions such as the Rolls-Royce Sistema De Control Remoto, which excels in remote monitoring and control, and the Rolls-Royce Loop Thruster Control, specialized for marine propulsion systems.

Alongside the Aquamaster-Rauma mpc-200, we also offer the Rolls-Royce PPSMI 2 and MEA-403 for enhanced process monitoring and environmental compliance, providing a comprehensive automation ecosystem. The Rolls-Royce H1127.0101 and 389-496-00 models deliver additional support in signal processing and hardware interface roles, ensuring a seamless operational flow. Furthermore, the integration of the Rolls-Royce 222-653 Plc2001b.PCB and Rolls-Royce ATC-3-A7033172 enhances the system’s programming flexibility and control precision, while the Rolls-Royce Fmv 25B offers supplementary feedback mechanisms that enhance system responsiveness. These models, when combined with the Aquamaster-Rauma mpc-200, deliver a holistic automation solution capable of tackling the most challenging industrial automation tasks. In summary, the Rolls-Royce Aquamaster-Rauma mpc-200 is a state-of-the-art automation controller designed for high-demand environments within the power industry, petrochemical processing, and general automation sectors. Its superior input/output capacity, rugged durability, and advanced performance metrics set it apart from other Rolls-Royce automation products.

When deployed alongside complementary models such as the Rolls-Royce MPC-200/MPC220, CanMan SLIO 02, Sistema De Control Remoto, PPSMI 2, MEA-403, and Loop Thruster Control, it forms the backbone of a sophisticated and reliable automation infrastructure. Whether optimizing turbine operations, managing complex chemical processes, or streamlining general automation tasks, the application of Aquamaster-Rauma mpc-200 in power industry, petrochemical, and general automation environments ensures enhanced operational efficiency, safety, and scalability for the future.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-