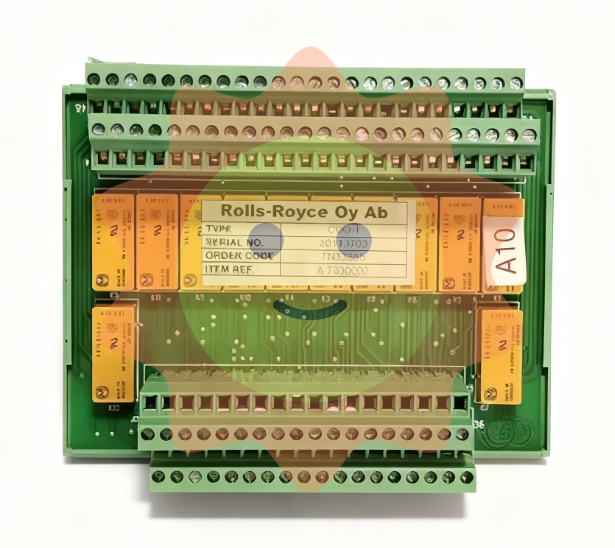

Rolls-Royce CanMan SLIO02 - Controller Network

The Rolls-Royce CanMan SLIO02 represents a pinnacle in automation technology, designed specifically for demanding environments within the power industry, petrochemical sectors, and general automation applications. Engineered with precision and durability, this model is renowned for its robust input/output (I/O) capacity, high performance under extreme conditions, and seamless integration capabilities, making it an indispensable asset in complex industrial automation systems. At its core, the Rolls-Royce CanMan SLIO02 boasts an impressive I/O configuration with support for up to 128 digital inputs and outputs, complemented by analog channels that handle a wide range of signal types. This extensive capacity ensures comprehensive monitoring and control of diverse industrial processes. The device features high-speed data processing capabilities, achieving response times well below 10 milliseconds, which is critical for real-time automation tasks. Its rugged construction adheres to IP67 standards, providing exceptional resistance to dust, water, and mechanical shocks, which are common challenges in harsh industrial environments such as petrochemical plants and power generation facilities. The CanMan SLIO02 also supports advanced communication protocols including Modbus, Profibus, and Ethernet/IP, facilitating seamless integration with existing control networks and enabling scalable automation solutions.

In real-world applications, the Rolls-Royce CanMan SLIO02 excels in scenarios requiring dependable and precise control over complex systems. Within the power industry, it is extensively utilized for turbine controls, generator monitoring, and switchgear automation, where reliability and quick response times are vital. In petrochemical plants, the CanMan SLIO02 manages critical process controls such as temperature regulation, pressure management, and safety interlocks, ensuring operational efficiency and compliance with safety standards. Additionally, its adaptability makes it a preferred choice in general automation tasks, including assembly line control, robotic coordination, and facility management, where diverse I/O requirements and robust network communication are essential. When compared to other Rolls-Royce automation products, the CanMan SLIO02 offers unique advantages that distinguish it in the product lineup. For instance, while the Rolls-Royce CanMan SLIO 01 provides a solid foundation for automation control, the SLIO02 enhances performance with doubled I/O capacity and improved processing speeds, making it more suited for large-scale applications. Unlike the Rolls-Royce MPC-300, which focuses primarily on modular process control, the CanMan SLIO02 delivers a more comprehensive I/O interface and superior environmental resilience.

Furthermore, in contrast to the Rolls-Royce Panel Control units, which are often limited to user interface functionality, the CanMan SLIO02 operates as a full-fledged controller capable of autonomous decision-making and complex data handling. Alongside the Rolls-Royce CanMan SLIO02, complementary models such as the Rolls-Royce MEG-100-101-102 and Rolls-Royce 5880-PC1026 REV.A offer specialized functions including power monitoring and control board integration, enhancing the overall automation ecosystem. The Rolls-Royce Brown Loop Thruster and Rolls-Royce Loop Thruster Control models provide auxiliary propulsion control, which can be effectively managed through the CanMan SLIO02’s versatile communication protocols. Additionally, solutions like the Rolls-Royce KAMEWA R160637A and Rolls-Royce JC 600-0079 deliver mechanical actuation capabilities that seamlessly align with the automation commands issued by the CanMan SLIO02, creating a synchronized operational environment. For enhanced system scalability and redundancy, the Rolls-Royce 16129 and Rolls-Royce WRC1021D REV.C modules integrate well with the SLIO02 platform, ensuring uninterrupted performance in critical applications.

The application of CanMan SLIO02 in power industry, petrochemical, and general automation contexts highlights its adaptability and reliability. Whether it is regulating turbine output in a power plant, managing safety protocols in a chemical processing unit, or orchestrating automated manufacturing lines, the CanMan SLIO02 stands out as a cornerstone of Rolls-Royce automation products. Its combination of high I/O density, rapid processing, and robust construction ensures that it consistently meets and exceeds the stringent demands of modern industrial automation. In summary, the Rolls-Royce CanMan SLIO02 is a high-performance automation controller tailored for mission-critical applications in power generation, petrochemical operations, and diverse automation processes. Its advanced technical features, superior durability, and extensive integration options position it ahead of many peers within the Rolls-Royce automation portfolio. Coupled with complementary models such as the Rolls-Royce MPC-300, Rolls-Royce MEG-100-101-102, and Rolls-Royce Brown Loop Thruster, the CanMan SLIO02 forms the backbone of efficient, reliable, and scalable industrial automation solutions. Choosing the Rolls-Royce CanMan SLIO02 means investing in a future-proof system that delivers operational excellence across complex industrial landscapes.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-