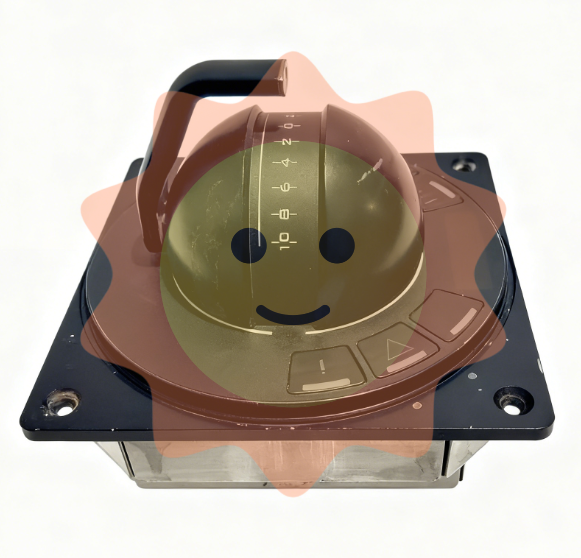

Rolls-Royce Remote Control System Node - Remote Control System Node

The Rolls-Royce Remote Control System Node represents a pinnacle in advanced automation technology, specifically engineered to meet the rigorous demands of the power industry, petrochemical facilities, and general automation environments. Designed for seamless integration and robust performance, this system node offers exceptional input/output capacity, durability, and operational reliability, making it a cornerstone in critical infrastructure control systems. At its core, the Rolls-Royce Remote Control System Node features an expansive I/O architecture capable of handling up to 128 input signals and 96 output channels. This extensive I/O capability ensures that complex automation processes can be managed efficiently from a centralized node, reducing system latency and improving real-time responsiveness. Built with industrial-grade components, the node boasts a ruggedized enclosure rated to IP67, ensuring superior resistance against dust, moisture, and harsh environmental conditions commonly found in power plants and petrochemical plants. Its operational temperature range spans from -40°C to +85°C, allowing it to function reliably in extreme climates without compromising performance. Performance metrics of the Remote Control System Node highlight its ultra-fast data processing speeds, with an internal CPU clock frequency optimized to handle real-time control loops and diagnostics within milliseconds.

Coupled with its advanced communication protocols supporting CANbus, Profibus, and Ethernet/IP, the node enables seamless interoperability with existing automation networks. The system’s embedded firmware supports fault-tolerant operations, featuring automatic failover and self-diagnostics to minimize downtime and enhance system safety. In real-world applications, the Rolls-Royce Remote Control System Node excels in scenarios requiring precise and reliable control of distributed automation equipment. In the power industry, it is instrumental in managing turbine control systems, load balancing, and grid stabilization processes. Petrochemical plants utilize the node for monitoring and controlling safety-critical valves, pumps, and process instrumentation, ensuring compliance with stringent safety standards. In general automation, it serves as a versatile controller for assembly lines, robotics coordination, and environmental control systems. Compared to other Rolls-Royce automation products, the Remote Control System Node stands out for its superior scalability and environmental resilience. For example, while the Rolls-Royce MPC-200 (A 7021100) and MPC-210 are tailored primarily for modular process control with moderate I/O requirements, the Remote Control System Node outperforms these models by offering higher I/O density and enhanced fault tolerance.

Similarly, when compared to the Rolls-Royce CANMAN SLIO 02 and Canman Slio 01 modules, which focus on discrete signal acquisition and local I/O expansion, the Remote Control System Node integrates these capabilities while providing advanced processing power and multiple communication interfaces, making it a more comprehensive solution. Alongside the Rolls-Royce Remote Control System Node, we also offer complementary products such as the Rolls-Royce Load Control DQ96-c, ideal for dynamic load management; the Rolls-Royce Loop Thruster Control for marine and industrial thruster automation; and the Rolls-Royce Aquamaster AQM 4 series, designed for precision marine propulsion control. Additionally, the Rolls-Royce PFC-03 and PFC-3 power factor controllers enhance energy efficiency in power systems and can be seamlessly integrated with the Remote Control System Node to deliver holistic automation solutions. For extensive automation networks, the Rolls-Royce RREMC1 Rev B and the Rolls-Royce 5880-PC1024 modules provide enhanced remote monitoring and control capabilities that complement the node’s functionality.

The application of the Rolls-Royce Remote Control System Node in the power industry, petrochemical, and general automation sectors is well documented and trusted globally. Its ability to withstand demanding operating conditions while delivering precise control and rapid response times makes it an indispensable asset in critical infrastructure projects. By leveraging its compatibility with other Rolls-Royce automation products, customers can design fully integrated, scalable systems tailored to their specific operational needs. In summary, the Rolls-Royce Remote Control System Node delivers unmatched performance, durability, and flexibility. Whether utilized in high-stakes power generation environments, complex petrochemical processing plants, or diverse general automation setups, it ensures optimal control and reliability. When paired with products like the Rolls-Royce GWY01, Rolls-Royce 704430, and Rolls-Royce ACP-04S19-002, the node becomes part of a robust ecosystem of automation solutions engineered for excellence. For organizations seeking state-of-the-art control technology, the Rolls-Royce Remote Control System Node remains the definitive choice within the extensive portfolio of Rolls-Royce automation products.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-