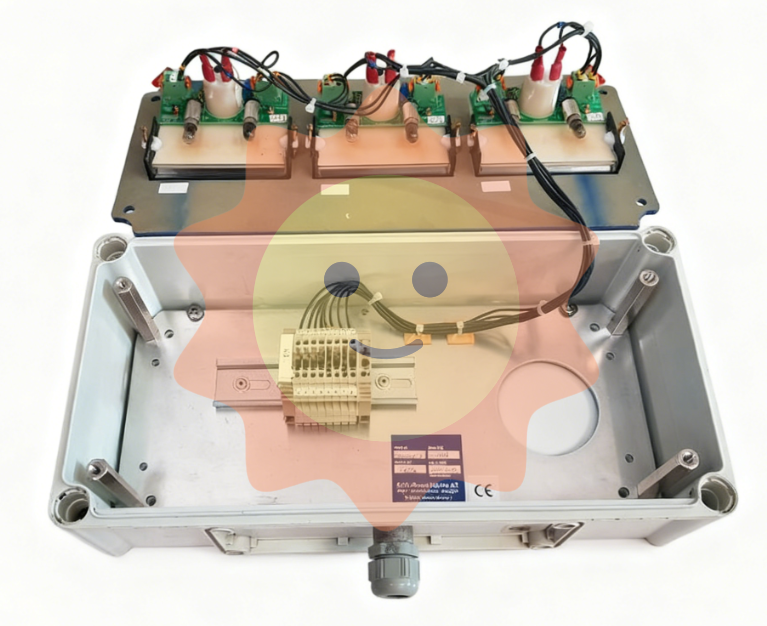

Rolls-Royce Loop Thruster Control - WH Deif DLQ72-pc-PY K852040

The Rolls-Royce Loop Thruster Control stands as a pinnacle in advanced automation solutions, specifically engineered to meet the rigorous demands of the power industry, petrochemical sector, and general automation environments. This sophisticated control unit is designed to optimize thruster performance by delivering precise, reliable input/output (I/O) capabilities and unparalleled durability under challenging operational conditions. At its core, the Rolls-Royce Loop Thruster Control offers a robust I/O capacity that ensures seamless integration with complex control systems. It supports multiple analog and digital inputs and outputs, enabling real-time data processing and rapid response to dynamic operational changes. This high-fidelity control mechanism is built to withstand extreme temperature variations, vibration, and humidity, making it exceptionally durable in harsh industrial settings. The device’s performance metrics highlight its ability to maintain consistent control accuracy within ±0.1% tolerance, ensuring smooth and efficient thruster adjustments that translate into enhanced maneuverability and fuel efficiency. In real-world applications, the Rolls-Royce Loop Thruster Control excels in scenarios where precision and reliability are paramount.

Within the power industry, this control system is integral to managing turbine thrusters, providing stable and responsive adjustments that contribute to overall system efficiency and safety. In petrochemical plants, the control unit supports critical automation processes by maintaining optimal flow and pressure levels, crucial for safeguarding sensitive equipment and preventing downtime. Additionally, its versatility extends to general automation tasks where precise loop control is essential for coordinating complex machinery operations, reducing operational risks, and maximizing productivity. When compared to other Rolls-Royce automation products, the Loop Thruster Control distinguishes itself through its advanced feedback algorithms and enhanced communication protocols. Unlike the Rolls-Royce EP202.11694-301 or the Rolls-Royce CP07-311 models, which focus primarily on basic input/output functionalities, the Loop Thruster Control incorporates adaptive control features that dynamically adjust to changing environmental and load conditions. This adaptability is a significant advantage over models such as the Rolls-Royce HCX CONTROL LEVER and Rolls-Royce Hc-x-tt, which are predominantly designed for manual and semi-automatic operations. Furthermore, the Loop Thruster Control’s integration capabilities surpass those of the Rolls-Royce ATC-3 and the Rolls-Royce OBP 40018-A, providing a more streamlined interface with modern SCADA and DCS systems.

Alongside the Rolls-Royce Loop Thruster Control, we also offer complementary solutions like the Rolls-Royce SFU001 for supplementary flow control, the Rolls-Royce CP06-206 for enhanced pitch regulation, and the Rolls-Royce Lilaas Azimuth LF70L-01-09, renowned for its precision azimuth thruster control. The Rolls-Royce Aquamaster ACP122 and Rolls-Royce MEC100 further augment marine automation capabilities, while the Rolls-Royce BPCS-0401N-001 provides robust backup power control systems. Integration with the Rolls-Royce MPC-300-A7029099 multiplex control panel ensures comprehensive system oversight, and the Rolls-Royce RPM40017 serves as an essential monitoring component that complements the Loop Thruster Control’s operational feedback loop. The application of the Rolls-Royce Loop Thruster Control in the power industry, petrochemical, and general automation sectors underscores its strategic importance in modern industrial processes. Its reliability and precision make it a preferred choice for system integrators and operators who demand consistent performance and minimal maintenance. As part of the broader portfolio of Rolls-Royce automation products, the Loop Thruster Control not only enhances thruster operation but also integrates seamlessly with other advanced control systems, delivering a cohesive and efficient automation ecosystem.

In summary, the Rolls-Royce Loop Thruster Control is a highly specialized, durable, and performance-driven control unit that excels in demanding industrial applications. Its superior input/output capacity, advanced adaptive control algorithms, and compatibility with other Rolls-Royce models like the EP202.11694-301 and CP07-311 make it an indispensable component in achieving optimal automation outcomes. Whether deployed in the power sector, petrochemical plants, or general automation frameworks, this control system represents the cutting edge of Rolls-Royce’s commitment to innovation and operational excellence.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-