FOXBORO FBM18 is the core industrial controller module in Emerson's Foxboro brand I/A Series DCS system. The standard model includes mainstream specifications such as FBM18 CP40, and belongs to the FBM (Fieldbus Module) series of control products. Unlike interface modules such as FBM07 and FBM12 that focus on signal conversion, FBM18 is positioned with "distributed control+local autonomous decision-making" as its core, integrating high-performance processors and independent control logic execution units. It can serve as a distributed control node for DCS systems, and can also achieve local control closed-loop when communication with the main controller is interrupted. It is a key control equipment to ensure the continuous and stable operation of industrial production processes.

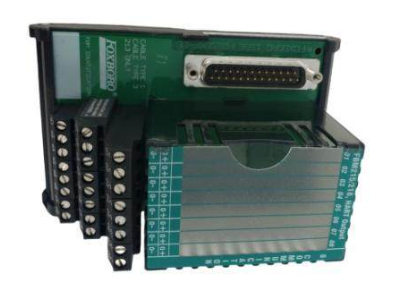

FOXBORO FBM18 Industrial Controller Module

Module Overview

FOXBORO FBM18 is the core industrial controller module in Emerson's Foxboro brand I/A Series DCS system. The standard model includes mainstream specifications such as FBM18 CP40, and belongs to the FBM (Fieldbus Module) series of control products. Unlike interface modules such as FBM07 and FBM12 that focus on signal conversion, FBM18 is positioned with "distributed control+local autonomous decision-making" as its core, integrating high-performance processors and independent control logic execution units. It can serve as a distributed control node for DCS systems, and can also achieve local control closed-loop when communication with the main controller is interrupted. It is a key control equipment to ensure the continuous and stable operation of industrial production processes.

The FBM18 module inherits the high reliability and strong anti-interference design of Foxboro DCS products, adopting a modular architecture of "control core+I/O expansion", supporting seamless integration of multiple types of FBM I/O modules, and can flexibly configure control scale according to process requirements. Its core advantages are reflected in fast control response, rich control algorithms, redundant fault tolerance, and wide environmental adaptability. It is widely used in process industries such as petrochemicals, power, metallurgy, and papermaking, which require high real-time and reliability control.

Core functional characteristics

2.1 High performance distributed control capability

The FBM18 module is equipped with a 32-bit high-performance microprocessor with a processing speed of up to 100 MIPS, capable of handling over 1000 control loops simultaneously. It supports a full range of control requirements, from simple PID control to complex advanced control (APC), including:

-Rich control algorithm integration: pre planted basic control algorithms such as PID (proportional integral derivative), PI, PD, as well as complex control strategies such as cascade control, ratio control, feedforward control, and split range control. At the same time, it supports users to customize control logic through Foxboro Control Language (FCL) to adapt to the control requirements of different processes. For example, in the temperature control of chemical reaction vessels, the jacket cooling water temperature can be used as a secondary loop through a cascade PID algorithm to achieve precise and stable control of the temperature inside the reaction vessel.

-High speed control cycle: The basic PID control cycle can be as low as 10ms, and the complex control logic cycle is ≤ 50ms, which is much faster than the signal processing speed of conventional interface modules. It can quickly respond to on-site process parameter fluctuations, effectively suppress overshoot and oscillation, and improve control quality.

-Local autonomous control function: It has the ability to switch between "master-slave control" and "local independent control" modes. Under normal operating conditions, as a distributed node of the DCS main controller, it receives instructions from the main controller and uploads data; When communication with the main controller is interrupted, it automatically switches to local control mode, maintains process stability based on preset control logic and historical parameters, and avoids production interruption caused by communication failure.

2.2 Flexible I/O Expansion and System Integration

FBM18 adopts a standardized bus expansion architecture, which can directly connect FBM07 (universal I/O), FBM12 (high-precision analog I/O), FBM10 (AC digital I/O) and other series of I/O modules through Foxboro Fieldbus bus. It supports up to 8 cascaded expansion modules, realizing centralized acquisition of analog and digital signals and unified output of control instructions.

In terms of system integration, the module supports high-speed communication with the main controllers (such as CP60, CP70), operator stations, and engineer stations of the I/A Series DCS, with a communication rate of up to 1Mbps. It adopts an industrial Ethernet protocol based on TCP/IP (optional) to ensure real-time interaction between control instructions and process data. Simultaneously supporting common industrial communication protocols such as OPC and Modbus, it can achieve data interoperability with third-party devices (such as PLCs and smart meters) to enhance system compatibility.

2.3 Fully redundant fault-tolerant and security protection mechanism

FBM18 has built a full level redundancy and protection system from hardware to software with the design goal of "zero fault shutdown":

-Hardware redundancy design: Supports dual redundancy (1+1) configuration of controller modules, with real-time synchronization of control logic and process data between the two modules. When the main controller fails, the backup controller can switch without disturbance within ≤ 100ms to ensure uninterrupted control process; Simultaneously supporting 24V DC redundant power input and bus redundant communication, completely eliminating the risk of single point failure.

-Data security protection: Equipped with non-volatile memory (NVRAM), it can permanently store control logic, parameter configuration, and historical data, ensuring that critical information is not lost even in the event of an unexpected power outage; Support data encryption transmission to prevent control instructions and process data from being tampered with or stolen, meeting industrial information security requirements.

-Fault diagnosis and interlocking: Real time monitoring of its own hardware status (such as processors, memory, communication interfaces) and the operation status of connected I/O modules. When a fault is detected, a fault code is immediately generated and uploaded to the DCS system, while triggering preset interlocking protection logic (such as emergency stop, valve reset) to prevent the fault from expanding and causing safety accidents.

2.4 Strong anti-interference and wide environmental adaptability

In response to the complex electromagnetic and environmental conditions in industrial sites, FBM18 adopts a multiple reinforcement design: at the hardware level, it achieves a 2500VAC/1-minute isolation between the control core and the I/O expansion channel, and the isolation voltage between channels reaches 1500VAC/1-minute, which can effectively resist electromagnetic coupling and common mode interference; Equipped with a dedicated electromagnetic shielding shell, it can withstand ± 4kV electrostatic discharge (ESD) impact and ± 2kV surge interference.

In terms of environmental adaptability, the module can operate stably in an extreme temperature range of -40 ℃ -75 ℃ and a humidity environment of 5% -95% without condensation, with a protection level of IP20 (module body). When combined with an explosion-proof shell, it can meet explosion-proof requirements such as Ex d IIB T6, and is suitable for harsh industrial scenarios such as high temperature, high humidity, high dust, and explosion-proof.

Key technical parameters

core processor

32-bit RISC processor with a processing speed of 100 MIPS

control ability

Maximum number of control circuits: 1000+; Basic PID control cycle: 10ms; complex control cycle: ≤ 50ms

I/O expansion capability

Support FBM series I/O modules, maximum expansion quantity: 8; Expansion bus: Foxboro Fieldbus

communication interface

1 x Foxboro Fieldbus master interface (1Mbps); 2 x Industrial Ethernet interface (10/100Mbps, supporting TCP/IP); 1 x Modbus/OPC communication interface (optional)

Redundant configuration

Controller 1+1 redundancy; Power supply 24V DC redundancy; Communication bus redundancy

Power requirements

24V DC redundant input, voltage range 18-32V DC; Maximum power consumption ≤ 15W (single module)

isolation performance

Control core and I/O channel: 2500VAC/1min; Between channels: 1500VAC/1min

working environment

Temperature: -40 ℃ -75 ℃; Humidity: 5% -95% (no condensation); Protection level: IP20 (body), IP67 (with dedicated casing)

mechanical properties

Installation method: 19 inch standard cabinet installation; Dimensions: 2U (88mm) x 175mm x 250mm (height x width x depth); Weight: Approximately 2.5kg

storage capacity

RAM:512MB; Flash:1GB; NVRAM: 16MB (non-volatile)

Typical application scenarios

The FBM18 module, with its core advantage of "distributed control+local autonomous decision-making", plays a critical role in various industrial scenarios that require extremely high control continuity and reliability. Typical applications include:

1. Petrochemical industry: In the catalytic cracking unit of large refineries, FBM18 serves as a distributed controller for the reaction regeneration system. It connects to the FBM12 module to collect parameters such as reactor temperature, pressure, and material level, and controls the feed rate and regenerator air volume through a cascade PID algorithm. Even if communication with the main DCS is interrupted, the unit can still maintain stable operation locally, avoiding significant losses such as catalyst deactivation.

2. Power industry: In the boiler feedwater control system of thermal power plants, FBM18 dual redundancy configuration is adopted, connected to FBM07 module to collect signals such as steam drum water level, feedwater flow rate, steam flow rate, etc. The speed of the feedwater pump is adjusted through three impulse PID control algorithm, and the redundant switching is undisturbed to ensure stable boiler water level and prevent steam drum full water or dry boiler accidents.

3. Metallurgical industry: In the converter steelmaking control system of the steel plant, FBM18 serves as the converter tilting and oxygen supply control node, connecting to the FBM10 module to collect digital signals such as converter angle and oxygen gun position. Through custom control logic, collaborative control of tilting speed and oxygen supply flow rate is achieved, and local control mode ensures continuous steelmaking process and improves steel quality.

4. Paper industry: In the control system of the net and press sections of large paper machines, FBM18 is connected to FBM12 module to collect parameters such as paper web weight, moisture, tension, etc. The ratio control and feedforward control algorithms are used to adjust the slurry flow rate and press pressure, achieving precise control of paper web quality and avoiding paper breakage accidents caused by communication failures.

5. Chemical industry: In the synthetic ammonia unit of large fertilizer plants, FBM18 serves as the control node for the synthesis tower, connecting various FBM I/O modules to collect key parameters such as temperature, pressure, and hydrogen nitrogen ratio inside the tower. Through complex advanced control algorithms, the circulating gas flow rate and reaction temperature are adjusted to ensure efficient and stable synthesis reaction. The redundant design meets the safety requirements of chemical production.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-