The GE IC200CHS022E compact I/O carrier module is the core connection and expansion component for small and medium-sized automation scenarios in the General Electric (GE) PACSystems RX3i series. As the "installation base" and "communication bridge" of the I/O module, it mainly realizes signal transmission, power distribution, and module management functions between the I/O module and the controller. This module adopts a compact structure design to achieve stable integration of multiple modules in a limited space, while also having flexible expansion capabilities, reliable signal processing performance, and adaptability to the diverse I/O control needs of industrial sites. It is widely used in small and medium-sized production lines, equipment single machine control, intelligent building monitoring and other scenarios.

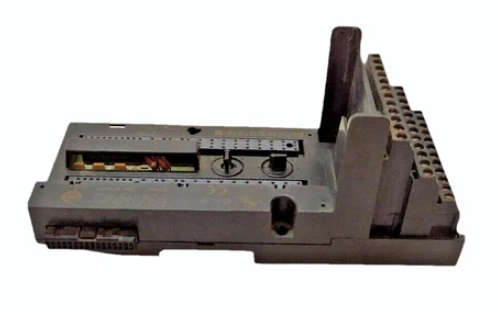

GE IC200CHS022E Compact I/O Carrier Module

Product Overview

The GE IC200CHS022E compact I/O carrier module is the core connection and expansion component for small and medium-sized automation scenarios in the General Electric (GE) PACSystems RX3i series. As the "installation base" and "communication bridge" of the I/O module, it mainly realizes signal transmission, power distribution, and module management functions between the I/O module and the controller. This module adopts a compact structure design to achieve stable integration of multiple modules in a limited space, while also having flexible expansion capabilities, reliable signal processing performance, and adaptability to the diverse I/O control needs of industrial sites. It is widely used in small and medium-sized production lines, equipment single machine control, intelligent building monitoring and other scenarios.

Core Features

1. Compact structure with high space utilization

Adopting highly integrated mechanical design and compact module size, it can save a lot of installation space in standard industrial cabinets, especially suitable for single machine equipment control or small control systems with limited space. Its compact structure does not sacrifice installation convenience, the module slot layout is reasonable, the insertion and removal are smooth, and it is easy to quickly deploy and maintain on site, effectively reducing the space cost of equipment integration.

2. Flexible I/O expansion capability

Equipped with 2 standard I/O module slots, compatible with various digital I/O, analog I/O, and special function modules (such as temperature acquisition, pulse output module, etc.) of GE PACSystems RX3i series. Users can flexibly match different types of I/O modules according to their actual control needs to achieve functions such as input and output of digital signals, acquisition and control of analog signals, etc., meeting the needs of I/O control scenarios from simple to complex, and improving the adaptability of the system.

3. Stable signal transmission and anti-interference performance

Built in optimized signal transmission circuit, using differential signal processing technology, effectively suppresses interference factors such as electromagnetic interference and voltage fluctuations in industrial sites, ensuring the accuracy and stability of I/O signal transmission. The internal signal path of the module is short, the signal attenuation is small, and it can quickly respond to the instructions of the controller, reduce control delay, and ensure the real-time and reliability of the control system.

4. Reliable power supply and protection mechanism

Support seamless compatibility with RX3i series power modules, providing stable DC power supply for the connected I/O modules. Built in overcurrent protection function, when the I/O module experiences overload or short circuit faults, it can quickly cut off the power supply circuit, protect the carrier module and I/O module from damage, reduce the risk of equipment failure, and improve the system's fault tolerance.

5. Convenient diagnosis and maintenance

Equipped with clear status indicator lights, including power indicator lights, communication indicator lights, module fault indicator lights, etc., staff can intuitively judge the operating status of the module (such as normal power supply, smooth communication, module faults, etc.) through the indicator lights, quickly locate the problem, reduce troubleshooting time, and lower maintenance costs. At the same time, the module supports diagnostic information exchange with the controller, and can remotely monitor the working status of the module and connected I/O modules through programming software, achieving predictive maintenance.

6. Wide compatibility

Not only is it compatible with various I/O modules and power modules of the RX3i series, but it can also seamlessly integrate with different models of controllers of the RX3i series without the need for additional configuration of adapter components, simplifying the system architecture. Its compatibility ensures smooth upgrades between old and new systems, and users can expand I/O functionality by adding this carrier module on top of the existing RX3i system, protecting their initial investment.

Key technical parameters

compatible system

GE PACSystems RX3i Series

Number of I/O module slots

2 of them

Compatible module types

RX3i series digital I/O, analog I/O, and special function modules

power supply voltage

24V DC (provided by RX3i series power module)

Working temperature range

-10℃ ~ 60℃

Storage temperature range

-40℃ ~ 85℃

relative humidity

5%~95% (no condensation)

Vibration level

Compliant with IEC 60068-2-6 standard, 10Hz~500Hz, acceleration 3g

Impact level

Compliant with IEC 60068-2-27 standard, peak acceleration of 15g, continuous for 11ms

protection function

overcurrent protection

communication interface

Communicate with RX3i controller through backplane bus

Installation method

Standard DIN rail installation, compatible with RX3i series system installation specifications

Mechanical dimensions (length x width x height)

Approximately 120mm x 80mm x 75mm (subject to actual product)

weight

About 0.3kg (excluding I/O module)

Applicable scenarios

The GE IC200CHS022E compact I/O carrier module is widely used in small and medium-sized industrial automation scenarios and space limited control environments due to its compact size, flexible expansion capability, and stable performance. Typical applications include:

-Single machine control for small and medium-sized production lines: such as small food packaging machines, beverage filling machines, small CNC machine tools, etc., by matching with a small number of I/O modules, the equipment can achieve functions such as start stop control, parameter acquisition, and fault alarm, achieving efficient control in limited space.

-Intelligent Building and Security Monitoring: Used for building lighting control systems, air conditioning and ventilation control, security access control, and video monitoring nodes. The compact structure adapts to the narrow space of building control cabinets, stably connects various sensors and actuators, and ensures the intelligent operation of building systems.

-Medical and laboratory equipment: such as clinical laboratory instruments, small laboratory experimental equipment, etc., are equipped with high-precision analog acquisition modules to achieve precise collection of experimental data and precise control of equipment. The small volume design adapts to the installation space inside the equipment.

-Small scale logistics and warehousing equipment, such as small conveyor belts, intelligent sorting units, and temperature and humidity monitoring devices for storage environments, can flexibly expand I/O interfaces to achieve automated operation of equipment and real-time monitoring of environmental parameters, adapting to the layout requirements of storage spaces.

-Old system upgrade and local expansion: In the existing RX3i series control system, when local expansion of I/O function is needed but space is limited, this module can be used as an ideal expansion component without the need to modify the original cabinet, quickly achieving system function upgrade.

Instructions for use

Before installation, it is necessary to confirm the compatibility of the carrier module with the RX3i series controller, power module, and I/O module, verify the module model and interface specifications, and avoid communication or power supply issues caused by model mismatch.

2. During installation, it is necessary to strictly follow the industrial electrical installation specifications to ensure that the module is well grounded, the guide rail is firmly fixed, and to avoid module loosening caused by vibration; When plugging and unplugging I/O modules, the operation should be gentle to avoid damaging the slots or module pins.

3. Before wiring, the system power must be cut off, and live wiring or module insertion and removal are strictly prohibited to prevent short circuits or static electricity from damaging the internal circuits of the module; After the wiring is completed, it is necessary to check whether the wiring terminals are firm to avoid poor contact and signal abnormalities.

4. During use, the module status indicator light should be checked regularly. If a fault indicator light is on, diagnostic information should be checked through programming software in a timely manner to troubleshoot I/O module faults, wiring issues, or power supply abnormalities.

5. The module should be installed in a well ventilated and dry environment, avoiding direct sunlight, high temperatures, humidity, or locations with dense dust. The working environment temperature and humidity should be controlled within the parameter range to ensure stable operation of the module.

6. If the module malfunctions, GE authorized after-sales service personnel should be contacted for inspection and repair. It is strictly prohibited to disassemble the module by oneself to avoid damaging the module structure or causing safety risks.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-