In ABB's automation control system, the ICSI16E1 digital input module plays a key role as the "front-end of on-site signal acquisition". Its core value lies in the centralized and standardized processing of dispersed on-site digital signals, which are then transmitted to controllers (such as ABB AC500 series PLCs and IRC5 machine human controllers) to provide reliable data support for control logic operations. Its specific positioning can be understood from three levels:

1. Accurate acquisition of on-site signals: The module is equipped with 16 independent digital input channels, each of which can accurately recognize the digital signals output by on-site sensors (high/low or on/off status). Whether it is a DC or AC signal type, it can be stably collected through internal signal conditioning circuits, effectively filtering out on-site interference signals and ensuring signal authenticity.

2. Reliable transmission and conversion of signals: Convert the collected analog digital signals (electrical signals) into digital logic signals recognizable by the control system, and achieve high-speed communication with the controller through backplane bus or industrial Ethernet. The transmission delay is controlled at the microsecond level to ensure real-time execution of control instructions.

3. System Expansion and Flexible Adaptation: Adopting standardized module design, it can be directly mounted on ABB standard I/O racks or distributed I/O stations, supporting seamless compatibility with various ABB controllers and other I/O modules (such as digital output modules, analog modules), providing a flexible and efficient solution for system I/O point expansion.

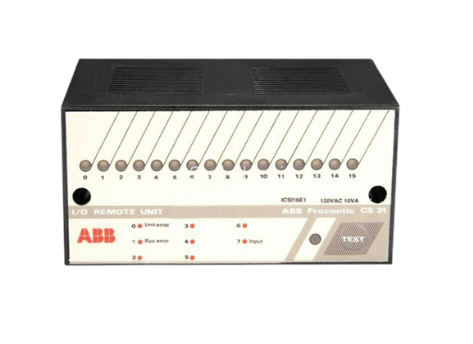

ABB ICSI16E1 Digital Input Module

Product positioning and core values

In ABB's automation control system, the ICSI16E1 digital input module plays a key role as the "front-end of on-site signal acquisition". Its core value lies in the centralized and standardized processing of dispersed on-site digital signals, which are then transmitted to controllers (such as ABB AC500 series PLCs and IRC5 machine human controllers) to provide reliable data support for control logic operations. Its specific positioning can be understood from three levels:

1. Accurate acquisition of on-site signals: The module is equipped with 16 independent digital input channels, each of which can accurately recognize the digital signals output by on-site sensors (high/low or on/off status). Whether it is a DC or AC signal type, it can be stably collected through internal signal conditioning circuits, effectively filtering out on-site interference signals and ensuring signal authenticity.

2. Reliable transmission and conversion of signals: Convert the collected analog digital signals (electrical signals) into digital logic signals recognizable by the control system, and achieve high-speed communication with the controller through backplane bus or industrial Ethernet. The transmission delay is controlled at the microsecond level to ensure real-time execution of control instructions.

3. System Expansion and Flexible Adaptation: Adopting standardized module design, it can be directly mounted on ABB standard I/O racks or distributed I/O stations, supporting seamless compatibility with various ABB controllers and other I/O modules (such as digital output modules, analog modules), providing a flexible and efficient solution for system I/O point expansion.

Core functional features

The ICSI16E1 digital input module is based on industrial design standards and integrates ABB's technical advantages in the field of I/O modules. It has the following outstanding functional features and can meet the demanding requirements of complex industrial environments:

-Multi channel independent acquisition and isolation protection: 16 input channels are independent of each other, each equipped with a photoelectric isolation circuit, with an isolation voltage of up to 2500V AC, effectively avoiding damage to modules and systems caused by strong electrical interference or signal crosstalk between channels, while reducing the impact of common mode interference and differential mode interference, and improving signal acquisition stability.

-Wide signal type adaptation capability: Supports multiple digital signal input types, compatible with both DC input (such as DC 24V, suitable for common NPN/PNP sensors) and AC input (such as AC 230V, suitable for signal acquisition in industrial high-voltage scenarios). Some models support input type switching through software configuration, with stronger adaptability.

-High speed response and real-time diagnosis: The module input response time can be as low as 1ms, which can quickly capture the instantaneous changes of on-site signals and meet the signal acquisition requirements of high-speed production lines; At the same time, it has a complete self diagnostic function, which can monitor the channel status (such as disconnection, short circuit), module power status, and communication status in real time. Fault information can be fed back through LED indicator lights or buses for quick troubleshooting.

-Flexible installation and wiring methods: Supports DIN rail installation, compatible with standard industrial control cabinets; The wiring adopts spring crimping or screw fastening methods, and the wiring terminals are compatible with multiple wire diameters (usually 0.5mm ²~2.5mm ²). The wiring operation is convenient and the contact is reliable, reducing signal failures caused by loose wiring.

-Industrial grade environmental tolerance: using high-strength flame-retardant shell and high-grade electronic components, the working temperature range covers -25 ℃~60 ℃, and the humidity adaptation range is 5%~95% (no condensation), which can resist vibration, impact and electromagnetic interference in industrial sites. The average time between failures (MTBF) exceeds 100000 hours, ensuring production continuity.

Key technical parameters

Module model

ABB ICSI16E1

ABB official unique model identification, used for selection and procurement

Number of input channels

16 independent digital input channels

Support simultaneous acquisition of signals from 16 on-site sensors

Input signal type

DC 24V/AC 230V (some models can be switched)

Adapt to NPN/PNP sensors and AC signal sources

Input voltage range

DC 18V~30V / AC 180V~264V

Wide voltage input, suitable for different on-site power environments

Input response time

Typical value 1ms, maximum not exceeding 3ms

Quickly capture changes in on-site signals

isolation method

Optoelectronic isolation between channels, isolation voltage 2500V AC (1 minute)

Strong anti-interference ability, protecting module security

communication interface

Supports PROFINET, EtherNet/IP, Modbus TCP

Compatible with mainstream industrial Ethernet protocols to achieve high-speed communication

Protection level

IP20 (module body), IP67 (some distributed models)

IP20 is suitable for control cabinets, IP67 supports on-site direct installation

Installation method

35mm DIN rail installation

Meet the requirements of industrial standardized installation

Applicable industries and typical application scenarios

The ICSI16E1 digital input module, with its multi-channel, high reliability, and strong adaptability, is widely used in the signal acquisition process of various industrial automation systems. Its core applicable industries and scenarios are as follows:

1. Automotive manufacturing industry: In the automotive welding production line, it is used to collect signals such as welding gun in place, fixture clamping status, and workpiece detection sensor signals; In the final assembly production line, the start stop status of the conveyor line and the signals indicating the proper assembly of components are collected to provide data support for PLC control of welding robots and linkage of conveyor equipment.

2. Mechanical processing industry: In the control system of CNC machine tools and machining centers, collect tool positioning signals, worktable limit signals, emergency stop button status signals, etc., to ensure that the machine tools operate safely and accurately according to preset logic; In the stamping production line, collect mold positioning signals and material detection signals to achieve automated control of the stamping process.

3. Energy and power industry: In the automation system of substations, collect the opening and closing status of circuit breakers, position signals of isolation switches, temperature inspection instrument alarm signals, etc; In wind farms, collecting wind turbine blade angle signals, cabin vibration signals, and hydraulic system pressure switch signals provides data for wind turbine operation monitoring and fault warning.

4. Logistics and warehousing industry: In automated three-dimensional warehouses, collect shelf position detection signals, stacker crane operation limit signals, and conveyor belt start stop status signals; In the express sorting system, collect package detection sensor signals and sorting port arrival signals to achieve precise sorting and transportation of packages.

5. Food and beverage industry: In the food filling production line, collect filling liquid level switch signals, bottle cap detection signals, and whether there are signals from conveyor belt materials; In sterilization equipment, temperature switch and pressure switch signals are collected to ensure that the food processing process meets safety standards.

Precautions for use

To ensure the long-term stable operation of the ICSI16E1 digital input module and the entire automation system, the following specifications must be strictly followed during installation, wiring, debugging, and maintenance:

-Installation environment specifications: The module body (IP20) should be installed in a well ventilated, dust-free, and non corrosive gas control cabinet, avoiding direct sunlight and rainwater erosion; The temperature inside the control cabinet should be controlled between -25 ℃~60 ℃, and the relative humidity should not exceed 95% (without condensation); The installation distance between modules and heating devices (such as frequency converters and power modules) should not be less than 15cm to ensure good heat dissipation. For IP67 models, on-site installation should avoid immersion in water to prevent severe vibration.

-Wiring operation specifications: Before wiring, the module power supply and on-site sensor power supply must be cut off to avoid module damage caused by live wiring; Strictly distinguish the power terminal, signal input terminal, and common terminal according to the module terminal diagram. DC input should pay attention to positive and negative polarity, and AC input should distinguish between phase and neutral wires. Reverse connection is strictly prohibited; Sensor cables and power cables need to be laid separately to avoid parallel wiring and reduce electromagnetic interference; After the wiring is completed, it is necessary to pull the cable firmly to confirm that the wiring is secure and prevent loosening.

-Debugging configuration specifications: Before debugging, it is necessary to confirm that the module model is compatible with the control system (PLC/robot controller), and configure the module parameters through ABB programming software (such as CODESYS, RobotStudio), including communication protocol, input signal type, filtering time, etc; After the configuration is completed, perform a single point test by triggering on-site sensors to observe whether the module LED indicator light and controller data respond normally; For high-speed signal acquisition scenarios, it is necessary to set the input filtering time reasonably (usually adjustable from 1ms to 10ms), balancing response speed and anti-interference ability.

-Daily maintenance points: Regularly check the status of module indicator lights every week, determine the module operation status through indicator lights (power light, channel status light, communication light), and promptly troubleshoot any abnormalities; Clean the dust on the surface of the module and wiring terminals every month to avoid poor contact caused by dust accumulation; Check the fastening of the wiring terminals once a quarter, especially on sites with high vibration, and re tighten the screws; Regularly backup module configuration parameters for quick recovery in case of failure.

-Fault handling specification: When a module experiences a channel unresponsive fault, first check the sensor power supply and cable connection, and then use a multimeter to measure whether the input signal is normal; If there is a communication failure, it is necessary to check the communication cable, IP address configuration, and switch status; If all module indicator lights are off, check the module power input and fuse (if any); When replacing a module, it is necessary to ensure that the new module model and firmware version are consistent with the original module. After replacement, the configuration parameters should be re imported and tested.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-