GE IS200AEPAH1AHD is a high-performance printed circuit board (PCB) specially designed by General Electric (GE) for industrial control systems. It belongs to the I/O module series of Mark VIe control systems and is positioned as an analog input/output (I/O) signal processing unit. This circuit board is widely used in heavy industries such as power generation, metallurgy, and chemical engineering, and plays a key role in the control systems of gas turbines, steam turbines, and wind turbines.

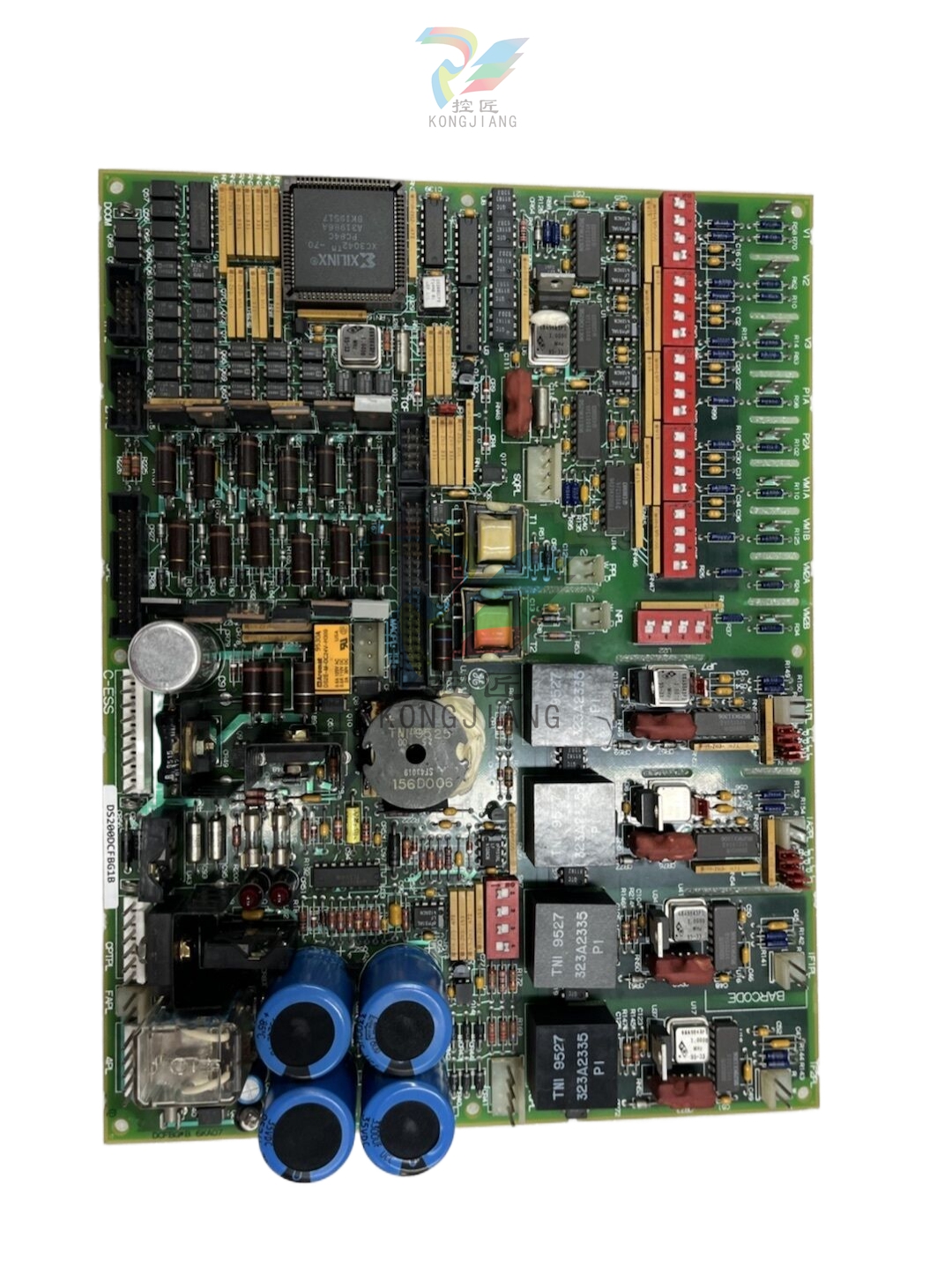

GE IS200AEPAH1AHD Printed Circuit Board

Basic Overview of Circuit Board

GE IS200AEPAH1AHD is a high-performance printed circuit board (PCB) specially designed by General Electric (GE) for industrial control systems. It belongs to the I/O module series of Mark VIe control systems and is positioned as an analog input/output (I/O) signal processing unit. This circuit board is widely used in heavy industries such as power generation, metallurgy, and chemical engineering, and plays a key role in the control systems of gas turbines, steam turbines, and wind turbines.

As a signal "relay station" between the control system and on-site equipment, its design integrates industrial grade anti-interference technology and high stability circuit layout, which can achieve precise acquisition, conversion, and output of analog signals in complex industrial electromagnetic environments, directly related to the response accuracy and operational reliability of the entire control system. It is one of the core hardware carriers for on-site control in the Mark VIe system.

Core functions and roles

1. Accurate acquisition of analog signals

This circuit board has multi-channel analog input function, which can centrally collect analog signals output by various sensors on site, including temperature (such as PT100 thermistor signal), pressure (such as 4-20mA pressure transmitter signal), flow rate, liquid level and other key process parameters. By using onboard high-precision signal conditioning circuits and A/D (analog/digital) conversion chips, weak analog signals are amplified, filtered, and noise suppressed to convert them into digital signals that can be recognized by the control system, ensuring the accuracy and stability of parameter acquisition and providing reliable data basis for control decisions.

2. Control signal conversion and output

After receiving digital control instructions from the Mark VIe main control unit, the circuit board converts the instructions into analog signals (such as 0-10V voltage signals or 4-20mA current signals) that can be directly driven by on-site actuators through a D/A (digital/analog) conversion module, driving devices such as regulating valves, frequency converters, and actuators to operate. At the same time, the output circuit has signal isolation function, effectively avoiding voltage fluctuations or interference signals from on-site equipment from being transmitted back to the control system, ensuring the safety of the core control unit.

3. Signal isolation and anti-interference protection

In response to common issues such as strong electromagnetic interference and grounding loops in industrial sites, this circuit board adopts a dual design of optoelectronic isolation and power isolation. Electrical isolation is achieved between the input/output channel and the motherboard circuit through optocouplers, with an isolation voltage of up to 2500V AC or higher, effectively blocking the propagation path of interference signals; At the same time, the onboard independent isolation power module provides stable power supply for the signal processing circuit, further enhancing anti-interference ability and ensuring the integrity of signal transmission under complex working conditions.

4. Status monitoring and fault feedback

The circuit board is equipped with a comprehensive self diagnosis and status monitoring circuit, which can monitor its own working status in real time, including power supply voltage, channel signal integrity, A/D/A conversion module working status, etc. When abnormal conditions such as channel failure, signal overload, module overheating, etc. are detected, a fault status signal will be immediately generated and uploaded to the main control system. At the same time, the onboard indicator lights (such as power light, fault light, channel status light) will visually indicate the fault location, making it easy for operation and maintenance personnel to quickly locate the problem.

Key technical characteristics

-High precision signal processing: equipped with A/D and D/A conversion chips with a resolution of 16 bits or higher, the analog input accuracy can reach ± 0.1% FS, and the output accuracy can reach ± 0.2% FS, meeting the requirements of high-precision industrial control scenarios; Supports adaptation to multiple signal types, compatible with common analog signals such as voltage, current, and thermal resistance without the need for additional conversion modules.

-High reliability circuit design: using industrial grade wide temperature element devices, the working temperature range covers -40 ℃~70 ℃, and can adapt to extreme industrial environments such as high and low temperatures; The circuit board adopts immersion gold technology to enhance the oxidation resistance and conductivity of solder joints, and extend their service life.

-Flexible channel configuration: Typically configured with 8-16 configurable input/output channels, some channels support software switching between input/output modes, and channel functions can be flexibly defined according to actual control needs to reduce system configuration costs.

-Complete hardware protection: equipped with overvoltage protection (parallel TVS transient suppression diodes at input/output terminals), overcurrent protection (series fuse for each output), short circuit protection and other functions, which can effectively resist the impact caused by on-site equipment failures or operational errors, and protect the core components of the circuit board.

-Standardized interface and compatibility: Adopting the Mark VIe system standard backplane bus interface, it can be directly inserted into the system rack and the main control unit to achieve high-speed data exchange without additional wiring; Compatible with mainstream configuration software such as GE Proficy iFIX and Intellution Fix, facilitating system integration and debugging.

Applicable scenarios and supporting systems

The GE IS200AEPAH1AHD printed circuit board, with its high precision and reliability, is mainly suitable for the GE Mark VIe control system and is widely used in the following scenarios:

1. Power generation industry: monitoring and control of temperature, pressure, vibration and other parameters of gas turbines and steam turbines; Analog signal processing for pitch and yaw systems of wind turbines.

2. Process industry: Collection and adjustment of process parameters such as liquid level, flow rate, and concentration in chemical and petrochemical production processes; Control of parameters such as furnace temperature and molten steel composition in the metallurgical industry.

3. Intelligent manufacturing: monitoring the motor speed, equipment operating pressure, and other status of large-scale production lines; Processing of analog signals such as position and torque for robot workstations.

Its core supporting system includes:

-Mark VIe main control unit (such as IS200DSPXH1A): receives data uploaded by the circuit board and issues control instructions;

-On site sensors and actuators, such as temperature sensors, pressure transmitters, electric control valves, etc., to achieve signal acquisition and instruction execution;

-Configuration and diagnostic software: such as GE Proficy Machine Edition, used for circuit board channel configuration, parameter calibration, and fault diagnosis;

-System power module: Provides stable DC power supply (usually 24V DC) to ensure the normal operation of the circuit board.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-