KD2406PTBX belongs to the ABB KD series terminal block module, which is designed with the concept of "standardization, modularity, and high safety". As a key connection node in DC systems, its core function is to achieve reliable connection, branch distribution, and signal transfer of wires in 24V DC circuits, solving problems such as loose wire connections, poor contact, and chaotic wiring in DC systems. This module can seamlessly integrate with ABB's PLC, contactors, sensors and other components to build a regular and stable DC control circuit, improving the maintainability and operational stability of the system, and adapting to the high-precision requirements of modern industrial control for circuit connections.

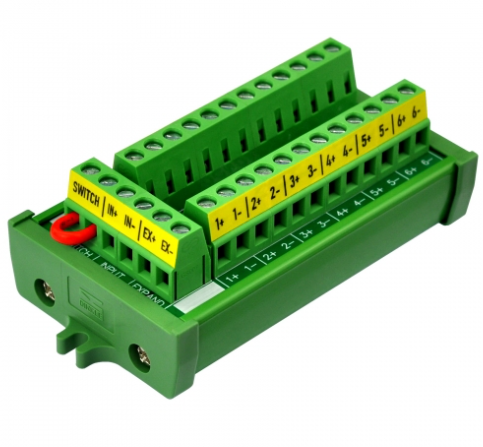

ABB KD2406PTBX 24V DC terminal block module

Product Overview

KD2406PTBX belongs to the ABB KD series terminal block module, which is designed with the concept of "standardization, modularity, and high safety". As a key connection node in DC systems, its core function is to achieve reliable connection, branch distribution, and signal transfer of wires in 24V DC circuits, solving problems such as loose wire connections, poor contact, and chaotic wiring in DC systems. This module can seamlessly integrate with ABB's PLC, contactors, sensors and other components to build a regular and stable DC control circuit, improving the maintainability and operational stability of the system, and adapting to the high-precision requirements of modern industrial control for circuit connections.

Core technical parameters

Technical parameters are the core basis for selecting terminal block modules. The key parameters of KD2406PTBX are as follows. In practical applications, please refer to ABB's official product manual:

1. Electrical performance parameters: The rated operating voltage (Ue) is DC 24V, which is precisely adapted to the most commonly used low-voltage DC power supply system in industrial control; The rated working current (In) is determined according to the terminal specifications, usually 10A-20A, which can meet the current transmission needs of most DC control circuits and small loads; The rated insulation voltage (Ui) shall not be less than 500V AC, with good insulation performance, effectively avoiding interference and leakage risks between DC systems and AC circuits; The contact resistance is extremely small (usually ≤ 10m Ω), which can reduce energy loss and heat generation during current transmission.

2. Wiring adaptation parameters: The supported wire types include single stranded hard wires and multi stranded soft wires (matched with wire ears or cold pressed terminals). The wire cross-sectional area adaptation range is usually 0.5mm ² -2.5mm ², and the corresponding specification wire can be selected according to the actual current demand; The wiring method adopts spring crimping or screw crimping design (depending on the model), which is firm and has excellent anti vibration performance, avoiding loose wiring caused by equipment operation vibration.

3. Environmental and protection parameters: The working environment temperature range is -40 ℃~+85 ℃, which can adapt to extremely cold outdoor scenes and high-temperature industrial workshops; The protection level of the shell is IP20, which can prevent solid foreign objects such as fingers from entering and meet the installation protection requirements inside the control cabinet; The relative humidity adaptation range is ≤ 95% (no condensation), suitable for humid environments such as basements and workshops.

4. Mechanical performance parameters: The module has a mechanical lifespan of over 1000 wiring operations, meeting the needs of frequent maintenance and circuit adjustments; The installation method is compatible with standard 35mm DIN rails, easy to install and disassemble, and the impact resistance meets IEC standards.

Structural characteristics and core advantages

1. Modular and orderly design

The KD2406PTBX adopts a standardized modular structure, compact size, and modular design that allows multiple modules to be tightly arranged on DIN rails, greatly saving installation space inside the control cabinet. The module is clearly labeled with terminal numbers, voltage levels, and other identifiers for quick identification during wiring, effectively avoiding wiring errors; At the same time, the module supports the combination of labeled terminals, separators, and other accessories of the same series as ABB, further improving the regularity of wiring and reducing the difficulty of line troubleshooting during later operation and maintenance.

2. Secure and reliable connection performance

The core connecting components of the module are made of high conductivity copper alloy material, and the surface is treated with tin plating or nickel plating, which not only improves conductivity, but also enhances corrosion resistance and oxidation resistance, extending the service life; If a spring crimping structure is used, the constant pressure of the spring can ensure that the wire and terminal are always in close contact, without being affected by temperature changes and vibrations, completely solving the problem of "thermal expansion and contraction loosening" that may occur in traditional screw crimping; The shell is made of engineering plastic with a flame retardant rating of UL94 V-0, which has excellent high temperature resistance and aging resistance, and can effectively prevent fire risks caused by short circuits.

3. Efficient and convenient wiring and maintenance

In response to the wiring characteristics of "multi branch, multi signal" in 24V DC systems, the module is designed with multiple independent terminals, which can achieve circuit distribution functions of single input and multiple output, reducing the repeated laying of wires; The wiring operation is simple and efficient. If it is a screw crimping type, only a screwdriver is needed to complete the tightening and dismantling of the wire; If it is a quick connect type, some specifications support "tool free" wiring, which can be directly connected by inserting wires, greatly improving wiring efficiency. During operation and maintenance, if it is necessary to replace wires or troubleshoot faults, the corresponding terminals can be operated separately without affecting other circuits, reducing maintenance costs.

4. Strong anti-interference and adaptability

24V DC system is commonly used for signal transmission. The module improves the creepage distance and electrical clearance through optimized insulation structure design, effectively suppressing electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring stable transmission of weak control signals, and avoiding equipment misoperation caused by interference; At the same time, this module is not only compatible with ABB's own DC control components, but also compatible with other brands of PLCs, sensors, relays, and other equipment, with a wide range of application adaptability.

Applicable scenarios and typical applications

Based on its 24V DC dedicated characteristics and reliable connection performance, the KD2406PTBX terminal block module is widely used in various low-voltage DC control and signal systems, with typical scenarios including:

-Industrial automation control: The wiring of I/O modules in PLC control systems, signal connections between sensors (such as photoelectric sensors and proximity switches) and controllers, and power distribution of actuating components such as solenoid valves provide reliable connection guarantees for the stable operation of automated production lines.

-In the field of instrumentation: 24V DC power input and signal output wiring for various detection instruments and analysis equipment, ensuring the accuracy of instrument data transmission and the stability of equipment operation.

-New energy equipment: 24V DC branch circuit connection for small photovoltaic energy storage systems, auxiliary control circuit wiring for new energy vehicle charging piles, adapted to the high reliability requirements of electrical components in new energy scenarios.

-Building and Security System: The 24V DC control circuit of the building automation system, as well as the power and signal wiring of security monitoring equipment (such as cameras and access control systems), ensure the stable operation of the building's intelligent system.

-In the field of medical equipment, the internal 24V DC circuit connection of small medical diagnostic instruments (such as blood pressure monitors and blood glucose meters) meets the strict standards for electrical safety and stability of medical equipment.

Key points for installation and maintenance

1. Installation precautions

-Before installation, it is necessary to confirm that the module model, rated voltage (DC 24V), and rated current match the actual circuit requirements. Check that the appearance of the module is not damaged, the terminals are not deformed or oxidized, and the insulation shell is not cracked.

-The installation location should be away from heat sources (such as contactors, heaters), water sources, and corrosive gases, avoid direct sunlight, ensure good ventilation inside the control cabinet, and prevent module aging or insulation performance degradation caused by high temperatures.

-When installing with a 35mm DIN rail, it is necessary to first firmly fix the rail, and then clip the module into the rail to ensure that the module is not loose; When installing multiple modules side by side, it is necessary to reserve a small gap according to the product manual requirements for heat dissipation and later disassembly.

-Before wiring, it is necessary to confirm that the circuit has been powered off and use a multimeter to check for any residual voltage; The insulation layer of the wire needs to be stripped of a suitable length (usually 6-8mm) to avoid poor contact caused by excessively long insulation layer or the risk of electric shock caused by too short insulation layer; When wiring, it is necessary to distinguish between the positive and negative poles, and strictly connect them according to the module identification to prevent the positive and negative poles from being reversed and damaging the equipment.

-After the wire is connected to the terminal, it needs to be gently pulled to confirm that the connection is firm and avoid virtual connection; If it is a screw crimping type, it is necessary to tighten the screws with a screwdriver of appropriate torque to avoid damaging the terminals or sliding screws with excessive force.

2. Daily maintenance and troubleshooting

-Regular inspection: Regularly inspect the appearance of the module every month, clean the surface dust and debris; Check for heating and discoloration of the terminals (such as blackening or yellowing), and for loose wires. If any abnormalities are found, power should be cut off in a timely manner; For screw crimping modules, the screws can be tightened regularly (every six months) to prevent loosening.

-Troubleshooting: If there are problems such as circuit failure or signal abnormalities, first turn off the power and then use a multimeter to check the continuity between terminals. Check whether it is due to loose wires, terminal oxidation, or internal module faults; If it is terminal oxidation, use fine sandpaper to gently polish the contact surface of the terminal and then rewire it; If there is an internal fault in the module (such as terminal burnout), it is necessary to replace it with a module of the same model in a timely manner.

-Wire replacement: When replacing wires, it is necessary to choose wires that are consistent with the original specifications. It is forbidden to use wires with a cross-sectional area that is too small to avoid terminal heating caused by overload; After replacement, it is necessary to reconfirm that the wiring is secure and the positive and negative poles are correct.

-Long term storage: uninstalled modules should be stored in a dry, ventilated, and non corrosive gas environment, avoiding direct sunlight and severe vibration. The storage temperature should be controlled between -40 ℃~+85 ℃, and the relative humidity should be ≤ 95% to prevent the modules from getting damp or aging.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-