The ABB LWN2660-6E power supply is a high-performance DC switching power supply in the ABB industrial power supply series, designed specifically for industrial automation control, power system secondary circuits, intelligent manufacturing equipment, and key electronic loads. Its core function is to stably convert AC input into DC output, providing reliable power supply for various control modules, sensors, actuators, and data acquisition equipment. This power supply integrates ABB's advanced power conversion technology and intelligent protection mechanism, and has the characteristics of high output accuracy, strong anti-interference ability, and stable operation. It can continuously output high-quality electrical energy in complex industrial environments and is the "power core" to ensure the continuous operation of industrial systems.

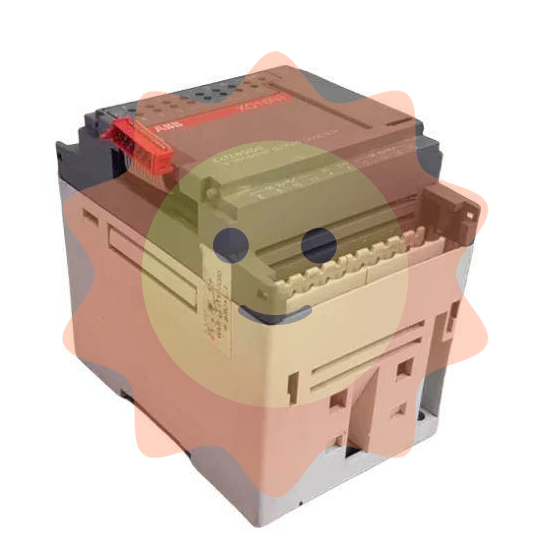

ABB LWN2660-6E power supply

Product Overview

The ABB LWN2660-6E power supply is a high-performance DC switching power supply in the ABB industrial power supply series, designed specifically for industrial automation control, power system secondary circuits, intelligent manufacturing equipment, and key electronic loads. Its core function is to stably convert AC input into DC output, providing reliable power supply for various control modules, sensors, actuators, and data acquisition equipment. This power supply integrates ABB's advanced power conversion technology and intelligent protection mechanism, and has the characteristics of high output accuracy, strong anti-interference ability, and stable operation. It can continuously output high-quality electrical energy in complex industrial environments and is the "power core" to ensure the continuous operation of industrial systems.

The model code has a clear technical direction: "LWN" is the product series code, representing the industrial grade DC switching power supply product line to which the power supply belongs; 2660 "usually corresponds to the core parameter configuration of the product, such as output power and voltage level; 6E "is the version identification and functional characteristic code, covering input voltage range, protection level, and special function adaptation information. It is the key basis for accurate product selection and application.

Core Features

1. High precision stable output and wide input adaptation

By adopting advanced PWM (Pulse Width Modulation) technology and high-precision feedback regulation circuit, the DC output voltage accuracy can reach ± 0.5%, and the output ripple and noise are controlled at extremely low levels (usually ≤ 1% of the rated output voltage), effectively avoiding the interference of voltage fluctuations on sensitive electronic devices. Supports wide range AC input (such as AC 85V-264V, please refer to the official manual for details), can adapt to different countries and regions' power grid voltage standards, and is compatible with 50Hz/60Hz power frequency, without the need for additional voltage conversion devices, improving the product's versatility and applicability.

2. Comprehensive intelligent protection mechanism

Integrate multiple safety protection functions, including overcurrent protection, overvoltage protection, over temperature protection, short circuit protection, and input undervoltage protection. When a load short circuit, output overload, or high ambient temperature occurs, the power supply will quickly activate the protection mode to ensure its own and load equipment safety through current limiting, output shutdown, or derating operation; After troubleshooting, some protection modes support automatic restoration of output, reducing the cost of manual intervention. In addition, the power supply is designed with anti reverse protection to prevent equipment damage caused by wiring errors.

3. Excellent anti-interference and environmental adaptability

The hardware design complies with industrial grade EMC (Electromagnetic Compatibility) standards, and through optimized circuit layout and shielding design, it has strong anti electromagnetic interference capabilities, effectively resisting electromagnetic radiation and conducted interference generated by industrial field frequency converters, motors, and other equipment. At the same time, its external electromagnetic radiation is also controlled at an extremely low level to avoid interfering with the operation of surrounding equipment. The shell is made of flame-retardant engineering plastic or metal material, with a protection level of IP20 or above (panel installation), supporting a wide temperature working environment of -20 ℃~60 ℃, and can adapt to harsh working conditions such as high temperature, dust, and vibration in industrial workshops.

4. High reliability and long lifespan design

Using industrial grade high-quality components such as long-life electrolytic capacitors, high-efficiency cooling fans, and temperature resistant semiconductor devices, the average time between failures (MTBF) of the product can reach over 100000 hours (under rated conditions). Optimization design is carried out for the cooling system, and some models adopt intelligent temperature control fans. The fan speed is automatically adjusted according to the power load and temperature, which not only ensures the cooling effect, but also reduces the operating noise and energy consumption, and extends the service life of the fan.

5. Convenient installation and monitoring functions

Adopting standardized rail installation (such as 35mm DIN rail) or panel installation method, the installation process is simple and fast, making it easy to integrate into industrial control cabinets. Equipped with clear LED status indicator lights, it can intuitively display the operating status of the power supply (such as normal output, fault, overload, etc.), making it convenient for on-site personnel to quickly judge the working condition of the power supply. Some models support remote monitoring function, which uploads output voltage, current and other parameters to the control system through analog signals or communication interfaces (such as RS485) to achieve remote monitoring and management of power operation status.

Key technical parameters

Input voltage range

AC 85V-264V (wide input)

input frequency

50Hz/60Hz(±10%)

Rated output voltage

DC 24V/DC 48V (configured according to model)

Rated output current

25A (corresponding to 24V output model)/12.5A (corresponding to 48V output model)

Output voltage accuracy

± 0.5% (under rated load)

Output Ripple and Noise

≤ 1% Vrms (rated output voltage)

conversion efficiency

≥ 90% (full load condition)

Working temperature range

-20 ℃~60 ℃ (ambient temperature)

Protection level

IP20 (panel installation)/IP30 (modular)

Installation method

35mm DIN rail installation/panel installation

certification standard

IEC 60950-1, UL 60950-1, GB 4943.1

Applicable scenarios

-Industrial automation system: provides stable DC power supply for core control equipment such as PLC controllers, DCS systems, human-machine interfaces (HMI), servo drives, etc., ensuring precise control and continuous operation of automated production lines, and avoiding production interruptions caused by unstable power supply.

-Secondary circuit of power system: used for supplying power to relay protection devices, measurement and control terminals, fault recorders and other equipment in substations and distribution rooms, ensuring the reliable operation of secondary equipment in the power system, and providing power support for the safety monitoring and fault handling of the power grid.

-In the field of intelligent manufacturing and robotics, we provide high-precision power supply for control systems, visual inspection equipment, and sensor modules of industrial robots, meeting the strict requirements for power stability in robot motion control and improving the automation accuracy of the production process.

-Data acquisition and monitoring system (SCADA): adapted to remote data acquisition terminals (RTUs), wireless communication modules, monitoring cameras and other equipment, providing stable power supply in remote areas or complex environments to ensure the continuity of data acquisition and transmission.

-Rail Transit and New Energy: Used for signal control systems in subways and light rails, as well as auxiliary control circuits for new energy charging stations, to maintain stable output in environments with large vibrations and temperature differences, ensuring the safe operation of related systems.

-Medical and laboratory equipment: Provide clean power for some mid to low end medical equipment (such as monitors, analytical instruments) and testing equipment in industrial laboratories to avoid the impact of voltage fluctuations on the accuracy of detection data.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-