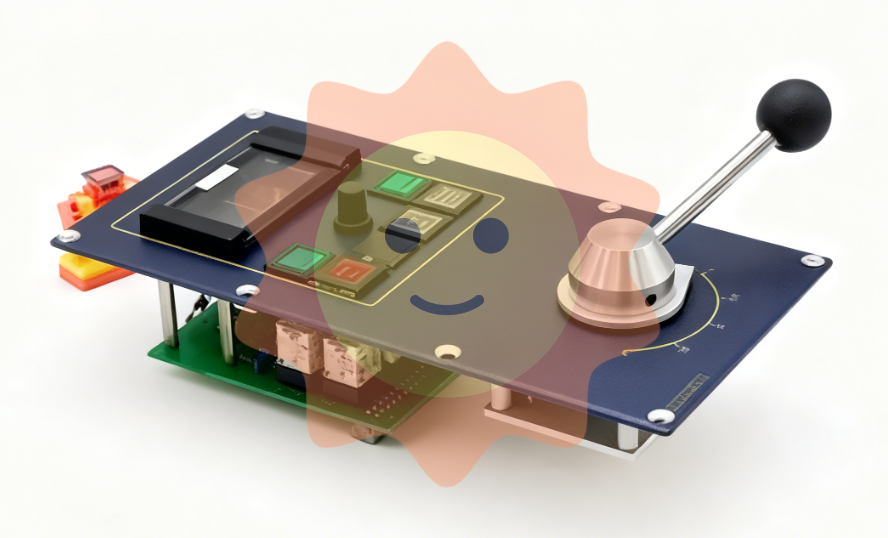

Rolls-Royce MEO-101 - PCB CARD

The Rolls-Royce MEO-101 stands as a pinnacle of engineering in the realm of industrial automation, specifically designed to meet the rigorous demands of the power industry, petrochemical sectors, and general automation applications. This advanced model embodies superior input/output capacity, exceptional durability, and high-performance reliability, making it an indispensable component for critical industrial processes. At the core of the Rolls-Royce MEO-101 is its robust input/output system that supports extensive signal integration and processing with remarkable precision. Capable of handling high-frequency data transmission, the MEO-101 ensures seamless communication between control units and field devices. Its input channels are optimized for both analog and digital signals, allowing versatile application across various automation tasks. Output capabilities are equally impressive, providing stable control signals to actuators and monitoring equipment, even under challenging environmental conditions. The device is engineered with advanced shielding and temperature-resistant components, guaranteeing operational stability across wide temperature ranges and harsh petrochemical environments. Durability is further enhanced by its corrosion-resistant enclosure and vibration-dampening mounts, which safeguard the unit against industrial wear and tear. Performance metrics for the MEO-101 reveal its suitability for demanding operational cycles.

With a mean time between failures (MTBF) exceeding industry standards, it delivers consistent uptime critical for power plants and chemical processing units where downtime translates to significant losses. The response time of the MEO-101 is optimized to below 10 milliseconds, ensuring real-time control and rapid fault detection. This responsiveness is crucial in automation systems where precision timing prevents operational hazards and ensures regulatory compliance. In real-world scenarios, the Rolls-Royce MEO-101 excels in applications such as turbine control in power generation, where it interfaces with sensor arrays to regulate fuel injection and monitor exhaust parameters. In petrochemical plants, it plays a vital role in controlling pump speeds and valve positions to maintain optimal chemical processing conditions. Additionally, its adaptability makes it ideal for general automation tasks like conveyor control, robotic assembly lines, and environmental monitoring systems, where reliability and precision are paramount. Comparing the MEO-101 with other Rolls-Royce automation products highlights its unique advantages.

While the Rolls-Royce CanMan SLIO02 and CanMan SLIO-2 models offer modular I/O solutions suitable for less intensive automation tasks, the MEO-101 surpasses them with enhanced input bandwidth and ruggedness. Unlike the Rolls-Royce MPCF1-10.4" which focuses on interface displays, the MEO-101 concentrates on core signal processing and control, offering a more specialized solution for industrial automation. The Rolls-Royce UN81 and UN924 models provide valuable communication protocols but lack the comprehensive I/O integration and durability present in the MEO-101. Similarly, the Rolls-Royce RSU001 and Control Panel units complement control room operations but cannot replace the field-level automation strength of the MEO-101. Alongside the Rolls-Royce MEO-101, we also offer the Rolls-Royce Neptune II MEF-101 and Rolls-Royce STEERING GEAR-TENFJORD for integrated system solutions. The Neptune II MEF-101 enhances marine and offshore automation, while the STEERING GEAR-TENFJORD adds precise maneuvering control, making them ideal companions in complex industrial setups. The Rolls-Royce AQM 4 ACP005 and Aquamaster AQM 4 provide specialized control in fluid management systems, complementing the MEO-101’s automation prowess.

For remote operations, the Rolls-Royce Remote Control System Node and UMAS UN-940 offer seamless connectivity and monitoring, ensuring a robust automation ecosystem. The application of MEO-101 in power industry, petrochemical, and general automation sectors is transformative, delivering unmatched performance and reliability. By integrating with other Rolls-Royce automation products such as the 25300016C control modules, the 5880-PC1025 Rev.D communication units, and the H1127.0101 / 68308 sensor arrays, the MEO-101 forms the backbone of sophisticated automated systems that require precision, durability, and adaptability. In summary, the Rolls-Royce MEO-101 is engineered for excellence in demanding industrial environments. Its superior input/output capacity, rugged design, and rapid response time make it the preferred choice for power generation, petrochemical processing, and general automation. When combined with complementary Rolls-Royce models, it enables a complete, reliable, and efficient automation solution that meets the highest industrial standards. For enterprises seeking to elevate their operational efficiency and safety, the Rolls-Royce MEO-101 and its associated product family represent the pinnacle of automation technology.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-