The PPC322AEV01 excitation control board is developed based on ABB's new generation excitation control platform and has four core characteristics: high control accuracy, strong anti-interference ability, flexible scalability, and high reliability. In terms of control accuracy, it adopts a 32-bit high-performance digital signal processor (DSP), combined with a high-precision A/D conversion module, with an excitation regulation accuracy of up to 0.1%, which can achieve precise control of excitation current and generator voltage. In terms of anti-interference ability, the control board adopts multi-layer PCB design and optoelectronic isolation technology, and has passed the IEC 61000 series electromagnetic compatibility certification, which can effectively resist electromagnetic interference, voltage fluctuations and other interference factors in industrial sites, ensuring stable transmission of control signals. Flexible scalability is reflected in the control board's support for multiple excitation regulation modes and communication protocols, which can be configured according to the type and operational requirements of the generator. At the same time, expansion interfaces are reserved for easy access to other functional modules of the excitation system. In terms of reliability, the control board adopts industrial grade high stability components, supports online self checking and fault redundancy switching, and has an average time between failures (MTBF) of over 80000 hours, which can adapt to the harsh operating environment of power generation sites.

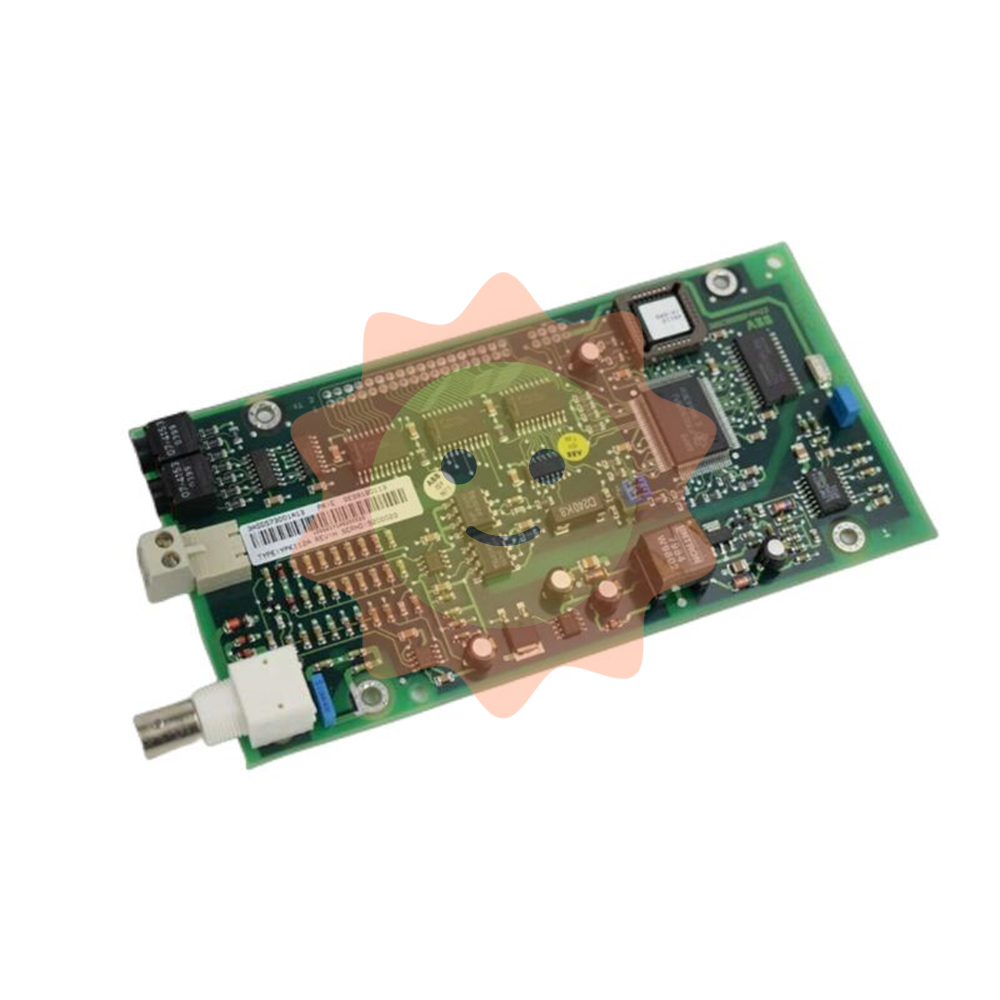

ABB PPC322AEV01 HIEE300697R1 excitation control board

Basic characteristics of control board

The PPC322AEV01 excitation control board is developed based on ABB's new generation excitation control platform and has four core characteristics: high control accuracy, strong anti-interference ability, flexible scalability, and high reliability. In terms of control accuracy, it adopts a 32-bit high-performance digital signal processor (DSP), combined with a high-precision A/D conversion module, with an excitation regulation accuracy of up to 0.1%, which can achieve precise control of excitation current and generator voltage. In terms of anti-interference ability, the control board adopts multi-layer PCB design and optoelectronic isolation technology, and has passed the IEC 61000 series electromagnetic compatibility certification, which can effectively resist electromagnetic interference, voltage fluctuations and other interference factors in industrial sites, ensuring stable transmission of control signals. Flexible scalability is reflected in the control board's support for multiple excitation regulation modes and communication protocols, which can be configured according to the type and operational requirements of the generator. At the same time, expansion interfaces are reserved for easy access to other functional modules of the excitation system. In terms of reliability, the control board adopts industrial grade high stability components, supports online self checking and fault redundancy switching, and has an average time between failures (MTBF) of over 80000 hours, which can adapt to the harsh operating environment of power generation sites.

Core Function Analysis

1. Multi mode excitation regulation control

The control board is equipped with a comprehensive excitation regulation algorithm, supporting multiple regulation modes that can be flexibly switched according to the operating conditions of the generator. The core regulation modes include: first, voltage regulation mode (AVR), which takes the generator terminal voltage as the control target, automatically adjusts the excitation current by detecting the deviation between the terminal voltage and the rated voltage in real time, ensuring that the generator terminal voltage is stable within the allowable range, and the voltage fluctuation deviation can be controlled within ± 0.5%, effectively improving the power quality; The second is the excitation current regulation mode (FCR), which aims to control the excitation current and is suitable for scenarios such as generator start-up, no-load trial operation, and fault emergency, ensuring stable output of the excitation system; The third is the Power Factor Regulation (PFR) mode, which automatically adjusts the excitation current by linking with the active and reactive power signals of the generator, achieving precise control of the generator's power factor and meeting the requirements of the power grid for power factor; The fourth is the grid connected collaborative regulation mode. When the generator is connected to the grid, the control board can receive the grid dispatch signal, achieve the coordinated matching of excitation regulation and grid operation, and improve the stability of the grid. Multiple adjustment modes are automatically or manually switched through logical judgment to meet the control requirements of different operating stages of the generator.

2. High precision signal acquisition and processing

The control board has comprehensive signal acquisition functions, which can real-time collect key operating parameters of the generator and excitation system, including electrical signals such as three-phase voltage, three-phase current, excitation voltage, excitation current, power factor, speed, as well as non electrical signals such as temperature and pressure. The acquisition module adopts a 16 bit high-precision A/D converter with a sampling rate of 1kHz, ensuring real-time and accurate signal acquisition. Through the built-in digital filtering algorithm, the control board can filter the collected raw signals, remove interference noise, and extract effective signals for adjusting control and status monitoring. At the same time, the control board supports signal calibration function, which can calibrate the zero and gain of the acquisition channel through software to ensure the acquisition accuracy during long-term operation.

3. Comprehensive fault protection and warning

To ensure the safe operation of the excitation system and generator, the control board is equipped with comprehensive fault protection and warning functions, which can quickly respond to common types of faults in the excitation system: firstly, overexcitation protection. When the excitation voltage or current exceeds the set threshold, the control board immediately triggers current limiting or demagnetization actions to avoid damage to the excitation winding due to overcurrent and overheating; The second is under excitation protection. When the excitation current is too low and causes the generator to lose excitation, an alarm signal is issued in a timely manner, and the excitation excitation action is triggered. If the demagnetization fault cannot be restored, the linked generator will trip to prevent asynchronous operation of the generator from causing impact on the power grid; The third is overvoltage/undervoltage protection. When the voltage at the generator terminal exceeds the safe range, voltage correction is performed by adjusting the excitation current. If the correction is ineffective, the protection action is triggered; The fourth is temperature protection, which collects temperature signals from key components such as excitation windings and rectifier cabinets. When the temperature exceeds the set value, a temperature warning is issued and load reduction measures are taken to avoid equipment overheating and damage. In addition, the control board has a fault memory function, which can record the time of fault occurrence, fault type, and operating parameters before and after the fault, providing a basis for fault analysis and troubleshooting.

4. Flexible communication and control interfaces

The control board is equipped with rich communication and control interfaces, supporting seamless integration with other modules of the excitation system, generator monitoring system, and power grid dispatch system. The communication interface includes RS485 serial interface, Ethernet interface, supporting communication protocols such as Modbus RTU/TCP, IEC 61850, etc. It can achieve remote issuance of control parameters, real-time uploading of operating data, remote reporting of fault information, and other functions, facilitating centralized monitoring and remote operation and maintenance of the excitation system. The control interface includes analog input/output interface and switch input/output interface, which can be connected to external equipment signals such as speed sensors, voltage transformers, current transformers, etc. At the same time, it outputs control signals to the excitation power cabinet, demagnetization switch and other actuators to achieve closed-loop control of the excitation system. In addition, the control board supports linkage control with PLC and DCS systems to meet the needs of comprehensive automation in power plants.

5. Convenient parameter configuration and operation and maintenance functions

The control board supports multiple parameter configuration methods, including configuring through local operation panel buttons, connecting to a PC through dedicated configuration software (such as ABB Excitation Configurator), and remotely configuring through communication networks. The configuration parameters include excitation regulation parameters, protection settings, communication parameters, etc. The configuration process is intuitive and convenient, supporting parameter backup and recovery to avoid parameter loss. In terms of operation and maintenance functions, the control board supports online self checking, real-time monitoring of its hardware circuit, software operation status, and interface communication status. When a fault occurs, it is prompted through LED indicator lights and fault codes. At the same time, the control board supports online firmware upgrades, and operation and maintenance personnel can download the latest firmware version through communication networks to upgrade, improve the functionality and performance of the control board, and reduce on-site operation and maintenance workload.

Key technical parameters

Applicable generator capacity

10MW~100MW synchronous generator

Input signal range

Voltage signal: 0~100V AC/DC; Current signal: 0~5A AC/4~20mA DC

A/D conversion accuracy

16 bits, sampling rate 1kHz

Excitation regulation accuracy

Voltage regulation accuracy ± 0.5%, current regulation accuracy ± 0.1%

Adjust response time

≤ 10ms (step response)

communication interface

1 RS485 interface (supporting Modbus RTU), 1 10/100Mbps Ethernet port (supporting IEC 61850)

I/O interface

8 analog inputs, 4 analog outputs, 16 switch inputs, 8 switch outputs

power supply

DC 24V ± 15% or DC 110V/220V ± 10%, power consumption ≤ 15W

working environment

Temperature: -25 ℃~65 ℃; Humidity: 5%~95% (no condensation); Protection level: IP20 (board body)

Installation method

Installation of guide rails or screw fixation inside the excitation control cabinet

Overall dimensions

220mm (length) × 160mm (width) × 40mm (height)

Electromagnetic compatibility level

IEC 61000-4-2 (ESD): ± 8kV contact discharge; IEC 61000-4-3(RS):10V/m

Applicable scenarios

The PPC322AEV01 excitation control board is widely used in the field of power generation due to its precise control performance, comprehensive protection functions, and flexible adaptability. Typical scenarios include:

1. Thermal power station: Used for excitation control of steam turbine generators in coal-fired, gas-fired and other thermal power stations. By accurately adjusting the excitation current, the voltage stability of the generator under different load conditions is ensured. At the same time, it cooperates with the coordinated control system of thermal power units to achieve precise output of power generation, improve the operating efficiency and grid adaptability of thermal power units.

2. Hydroelectric power station: In the excitation system of the hydroelectric generator in the hydroelectric power station, the control board can quickly adjust the excitation current according to the changes in turbine speed and grid load requirements, adapt to the load fluctuation characteristics of hydroelectric power generation, and ensure the safe operation of the hydroelectric generator and excitation system through perfect fault protection functions. It is suitable for large, medium and small hydroelectric power stations.

3. New energy power generation system: In the energy storage synchronous generators or backup generators of photovoltaic power plants and wind farms, the control board is used for excitation regulation and control, ensuring that the generator can stably output electricity when the output of new energy fluctuates, ensuring the reliability of the power supply of the new energy power generation system, and improving the coordinated operation ability between the new energy power generation system and the power grid.

4. Industrial self owned power stations: Used in the self owned power stations of large industrial enterprises such as steel, chemical, metallurgical, etc., for excitation control of self owned power generation equipment such as diesel generators and gas generators, ensuring that the self owned power stations provide stable and reliable electricity for enterprise production, and avoiding production interruptions caused by power grid outages or voltage fluctuations.

5. Emergency power generation system: In emergency power generation systems in important places such as hospitals, data centers, and transportation hubs, the control board is used for excitation control of emergency generators to ensure that they can quickly start and output stable voltage in the event of a power grid failure, providing continuous power supply for critical loads and ensuring the normal operation of the site.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-