The PS203PRESSPMPPS intelligent control module is an integrated solution developed by ABB for low-voltage distribution and control scenarios. Its core advantage lies in highly integrating control, protection, and monitoring functions, breaking the limitations of traditional discrete components in wiring, debugging, and operation. This module adopts a standardized interface design, which can quickly connect to various control systems and support seamless linkage with ABB's PLC, HMI and other equipment. It is also compatible with third-party mainstream automation products, greatly improving the flexibility and efficiency of system construction.

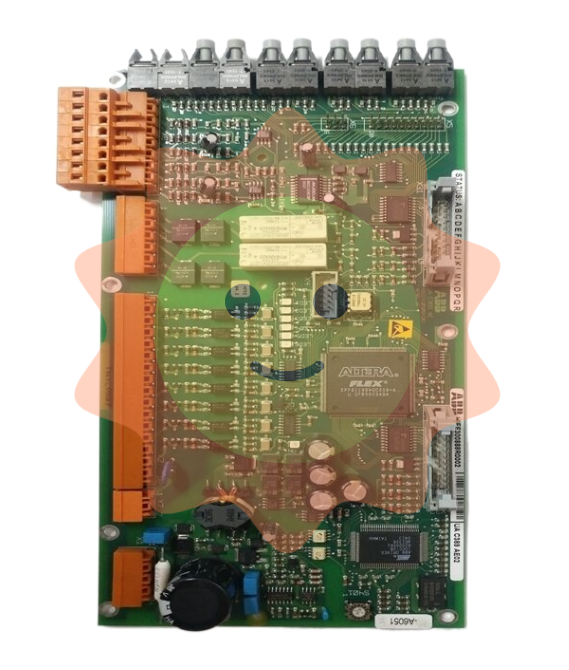

ABB PS203PRESSPMPPS Intelligent Control Module

Module Overview

The PS203PRESSPMPPS intelligent control module is an integrated solution developed by ABB for low-voltage distribution and control scenarios. Its core advantage lies in highly integrating control, protection, and monitoring functions, breaking the limitations of traditional discrete components in wiring, debugging, and operation. This module adopts a standardized interface design, which can quickly connect to various control systems and support seamless linkage with ABB's PLC, HMI and other equipment. It is also compatible with third-party mainstream automation products, greatly improving the flexibility and efficiency of system construction.

The module is packaged in an industrial grade shell, which has good resistance to electromagnetic interference, dust and moisture, and can adapt to a wide temperature working environment of -25 ℃~70 ℃. It can operate stably in complex scenarios such as factory workshops, data centers, and high-rise buildings, providing a guarantee for the safe and reliable operation of electrical systems.

Core functions

The PS203PRESSPMPPS module is based on "intelligent control+active protection" and is equipped with advanced microprocessor chips to achieve fine management and multi-dimensional security protection of loads. The specific functions are as follows:

1. Precise load control function

The module supports multiple control modes, including local manual control, remote PLC control, and timed control, which can be flexibly switched according to actual needs. Its control accuracy is as high as ± 0.1%, which can smoothly start and stop, adjust the speed or control the power of various loads such as motors, lighting, heating equipment, etc., effectively avoiding the losses caused by the current surge during load start and stop and extending the service life of the equipment. At the same time, the module has real-time feedback function of load status, which can synchronize operating parameters (such as current, voltage, power) to the control system to achieve closed-loop control.

2. Comprehensive security protection mechanism

To cope with various fault risks in the electrical system, the module integrates comprehensive protection functions, covering:

-Overload protection: When the load current exceeds the rated value, the module will trip accurately within 0.1-10 seconds to avoid overheating and burning of the circuit;

-Short circuit protection: Upon detecting a short circuit current (up to 10ms), the protection action is triggered to cut off the circuit and prevent the fault from expanding;

-Leakage protection: For equipment leakage situations, the leakage action current can be set as needed (30mA~500mA) to ensure personnel safety;

-Overvoltage/undervoltage protection: When the voltage fluctuation of the power grid exceeds the set range (such as AC 180V~260V), the module automatically cuts off the load to avoid equipment damage due to abnormal voltage;

-Phase loss protection: For three-phase loads, real-time monitoring of the voltage of each phase, immediate shutdown protection in case of phase loss, to prevent the motor from running and burning out due to phase loss.

3. Intelligent monitoring and data management

The module is equipped with high-precision sensors that can real-time collect key data such as current, voltage, power, power factor, temperature, etc., with a data update frequency of up to 10 times per second. Through the RS485 communication interface (supporting Modbus RTU protocol), data can be uploaded to the monitoring platform to achieve remote real-time monitoring of device operation status. At the same time, the module has a fault recording function, which can store the latest 50 fault information (including fault type, occurrence time, and fault parameters), providing accurate basis for operation and maintenance personnel to troubleshoot problems.

4. Energy saving and automation optimization

Based on intelligent algorithms, the module can automatically adjust output parameters according to load changes, such as reducing output power and energy waste when the motor is under light load; For lighting systems, support light sensing linkage control, automatically switch or adjust brightness according to environmental brightness, achieving energy saving and consumption reduction. In addition, the module supports multi module linkage control, which can realize complex automation logic through programming, such as sequential start stop of production lines, equipment linkage protection, etc., to improve production efficiency.

Key technical parameters

Accurately mastering the technical parameters of modules is the foundation for achieving reasonable system configuration. The core technical parameters of PS203PRESSPMCPS are shown in the following table:

parameter category

specific parameters

rated voltage

AC 220V/380V(50/60Hz)

rated current

1A/2A/5A/10A/16A/20A/25A/22A (multiple specifications available)

Control method

Local button, remote communication (RS485), analog quantity (4~20mA)

communication protocol

Modbus-RTU

Protecting Action Accuracy

±5%

Working temperature range

-25℃~70℃

Protection level

IP20 (module body), IP65 (with protective casing)

Installation method

DIN rail installation (35mm standard rail)

Dimensions (length x width x height)

108mm × 75mm × 90mm (standard specification)

Applicable scenarios

With the characteristics of integration, intelligence, and high reliability, the PS203PRESSPMPPS module is widely used in multiple fields, with typical scenarios including:

1. Industrial automation production line

In production lines such as automobile manufacturing, electronic processing, and food packaging, modules can serve as the core of motor control to achieve precise start stop and speed adjustment of conveyor belts, robotic arms, mixing equipment, etc. At the same time, through linkage protection functions, single device failures can be avoided from affecting the operation of the entire production line, improving production stability.

2. Building electrical system

In high-rise buildings such as shopping malls, office buildings, and hotels, modules can be used for the control and protection of lighting systems, air conditioning systems, and water pump systems. For example, energy-saving lighting can be achieved through timed control and light sensing linkage, and safe operation of air conditioning and water pump equipment can be guaranteed through overload and leakage protection, reducing operation and maintenance costs.

3. Data center and computer room

Data centers have extremely high requirements for power supply stability. Modules can be used to control UPS power supplies, precision air conditioning, and server cabinet cooling systems, monitor load current, voltage, and temperature parameters in real time, and trigger protection actions immediately in case of abnormalities to ensure continuous operation of the data center.

4. In the field of new energy

In photovoltaic inverters and energy storage systems, modules can control and protect the charging and discharging circuits, accurately adjust the charging and discharging currents, avoid damage to the battery caused by overcharging and overdischarging, and achieve real-time control of the operating status of the energy storage system through data monitoring.

5. Agricultural automation

In greenhouse and irrigation systems, modules can automatically control the start and stop of water pumps, fans, and heating equipment based on parameters such as soil moisture and environmental temperature, achieving automation and precision in agricultural production and improving agricultural production efficiency.

Installation and maintenance

1. Installation points

The module is installed using a 35mm standard DIN rail, and attention should be paid to the following during installation:

-The installation location should be away from strong electromagnetic interference sources (such as frequency converters) and high-temperature heat sources, and avoid direct sunlight;

-When wiring, it is necessary to strictly distinguish between the power end, load end, and communication end to ensure that the wiring is firm and avoid faults caused by virtual connections;

-At least 5mm spacing should be maintained between modules to ensure good heat dissipation;

-After installation, insulation testing is required to ensure that the insulation performance of the circuit meets the requirements.

2. Daily maintenance

The maintenance of modules is relatively simple, and daily attention should be paid to:

-Regularly clean the surface dust of the module to avoid dust accumulation and affect heat dissipation;

-By monitoring the operating parameters through the monitoring platform or local display screen, any abnormalities can be detected in a timely manner;

-Regularly check whether the wiring terminals are loose, especially for high current circuits;

-After a fault occurs, the problem can be quickly located through the fault recording function of the module. When replacing the module, attention should be paid to matching the specifications to avoid mixing models.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-