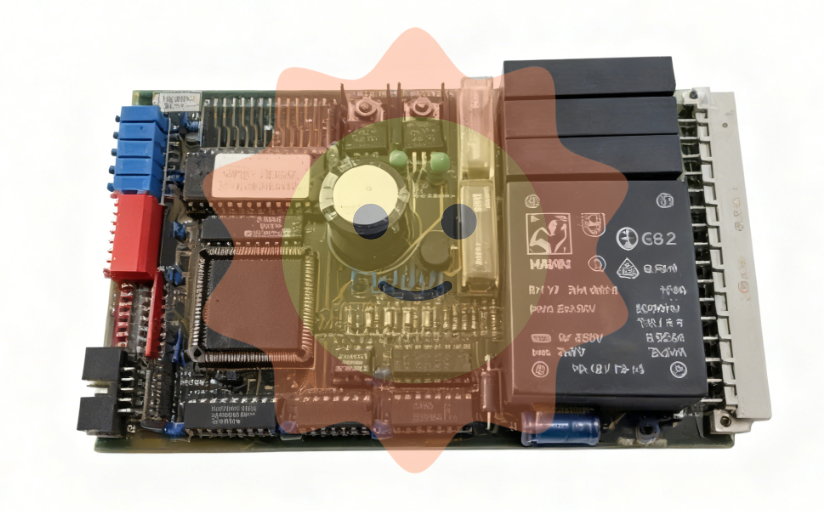

Rolls-Royce SLIO 01 - CANMAN Controlador Red

The Rolls-Royce SLIO 01 stands as a pinnacle of advanced automation technology, meticulously engineered to meet the rigorous demands of the power industry, petrochemical sectors, and general automation applications. This cutting-edge model integrates robust input/output capacities, unmatched durability, and precise performance metrics, making it an indispensable asset for complex industrial environments requiring reliability and efficiency. At its core, the Rolls-Royce SLIO 01 boasts an impressive input/output interface that supports high-speed data transfer and multi-channel connectivity. Designed to handle extensive digital and analog signals, it offers scalable input ranges up to 128 inputs and outputs, enabling seamless integration with a wide array of sensors, actuators, and control devices. The device operates with a response time of less than 1 millisecond, guaranteeing real-time processing capabilities essential for critical automation tasks. Constructed with industrial-grade materials and conforming to stringent IP67 standards, the SLIO 01 ensures exceptional resistance to dust, moisture, and extreme temperatures, thus delivering unparalleled durability in harsh operational conditions. Performance-wise, the SLIO 01 leverages advanced firmware algorithms optimized for predictive diagnostics and adaptive control.

This feature not only enhances system uptime but also reduces maintenance costs by proactively identifying potential faults before they escalate. Its modular architecture simplifies upgrades and expansions, allowing customers to tailor the system according to evolving industrial requirements. Furthermore, with integrated cybersecurity protocols, the SLIO 01 safeguards automation networks against unauthorized access and cyber threats, a critical advantage in today’s interconnected industrial landscapes. In real-world applications, the Rolls-Royce SLIO 01 excels wherever precision and reliability are paramount. In the power industry, it manages complex grid automation tasks, from turbine control to substation monitoring, ensuring continuous and stable power delivery. In petrochemical plants, the SLIO 01 automates process control loops, enhancing safety and efficiency in hazardous environments. Its versatility also shines in general automation settings, such as manufacturing assembly lines and water treatment facilities, where it orchestrates multifaceted operations with seamless coordination. When compared to other Rolls-Royce automation products, the SLIO 01 distinguishes itself through its superior scalability and rugged design. For instance, while the Rolls-Royce MPCF1-10.4" offers a robust human-machine interface solution and the Rolls-Royce CE01-02 series is designed for basic control tasks, the SLIO 01 delivers a comprehensive platform combining high I/O density with advanced processing power.

Unlike the Rolls-Royce POSCON, which focuses primarily on position control, the SLIO 01 integrates multiple control functions, making it a more versatile choice for complex automation systems. Additionally, models such as the Rolls-Royce HELICON 6865 and the Rolls-Royce Kamewa 1082 are renowned for marine propulsion and thruster control, whereas the SLIO 01 is optimized for industrial automation, highlighting its specialized role within the brand’s extensive portfolio. Alongside the Rolls-Royce SLIO 01, complementary products like the Rolls-Royce CU40-0106-50 and the Rolls-Royce CE06-31 expand your automation capabilities by offering enhanced communication protocols and auxiliary control modules. The Rolls-Royce ACP008 and Rolls-Royce WRC1021A provide further integration options for power management and system diagnostics, ensuring a holistic approach to automation infrastructure. For applications requiring precise sensor interfacing, the Rolls-Royce RSU001 and Rolls-Royce DC0033A modules deliver reliable signal conditioning and data acquisition solutions. Together, these models form a comprehensive ecosystem that maximizes performance and operational efficiency across diverse industrial scenarios.

The application of the SLIO 01 in power industry, petrochemical, and general automation sectors is facilitated by its compatibility with existing Rolls-Royce systems and its adaptability to future technological advancements. Its design philosophy emphasizes ease of installation and maintenance, reducing downtime during upgrades or repairs. Moreover, the SLIO 01 supports various industry-standard communication protocols, including Modbus, PROFIBUS, and Ethernet/IP, enabling seamless integration into legacy and modern control frameworks alike. In summary, the Rolls-Royce SLIO 01 represents a powerful fusion of durability, precision, and flexibility within the realm of Rolls-Royce automation products. Its exceptional input/output capacity, rapid response times, and rugged design make it ideally suited for demanding environments in the power industry, petrochemical plants, and general automation tasks. When paired with complementary models such as the Rolls-Royce MPCF1-10.4", CU40-0106-50, CE06-31, HELICON 6865, WRC1021A, ACP008, RSU001, and DC0033A, the SLIO 01 becomes a central component of a high-performance, reliable automation ecosystem. Whether upgrading existing systems or designing new automation frameworks, the SLIO 01 delivers operational excellence and future-proof scalability for industrial leaders worldwide.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-