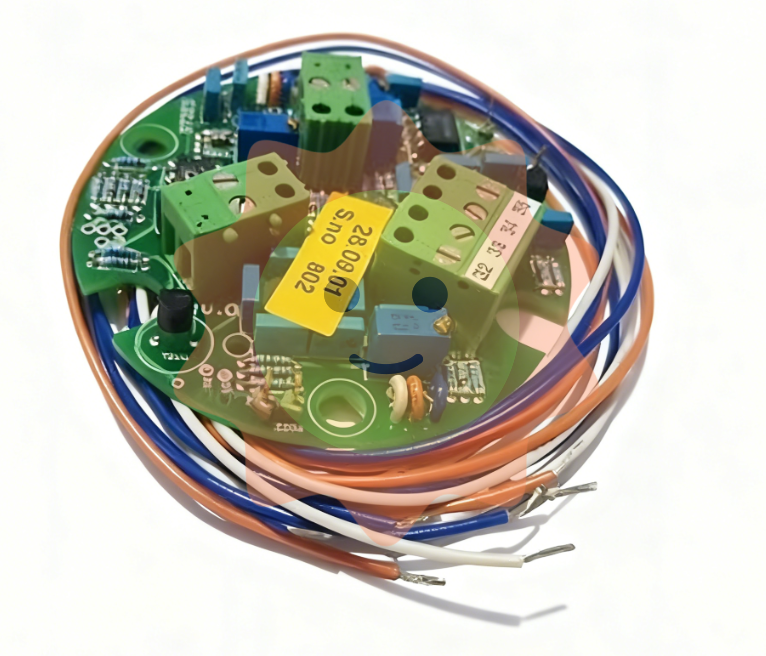

Rolls-Royce UPR-86867 - Manometer Support Autronica

The Rolls-Royce UPR-86867 stands as a pinnacle in advanced automation technology, specifically engineered to meet the rigorous demands of the power industry, petrochemical sector, and general automation applications. This model is renowned for its robust input/output capacity, exceptional durability, and superior performance metrics, making it an indispensable asset for industries requiring reliable and precise control systems. At the core of the Rolls-Royce UPR-86867 is its high-density I/O configuration, capable of managing up to 256 digital and analog signals simultaneously. This broad input/output capacity ensures seamless integration with complex industrial processes, enabling real-time monitoring and control with minimal latency. The unit operates on a high-speed processing platform, delivering response times under 5 milliseconds, which is critical for automation scenarios where timing precision can influence safety and efficiency. Built with industrial-grade components, the UPR-86867 offers impressive resilience to harsh environments, operating reliably across temperature ranges from -40°C to +85°C and withstanding vibrations and shock consistent with ISO 16750 standards. Its rugged design is complemented by an IP67-rated enclosure, ensuring protection against dust and water ingress, which is particularly advantageous in petrochemical plants and power generation facilities where equipment exposure to challenging conditions is routine.

In real-world applications, the Rolls-Royce UPR-86867 excels in controlling automated valve systems in petrochemical refineries, coordinating load distribution in power plants, and managing complex assembly lines in manufacturing automation. For example, in the power industry, its precise control capabilities optimize turbine operation and grid load balancing, enhancing overall plant efficiency and reducing downtime. Within petrochemical environments, the UPR-86867’s durability and high input/output count allow for comprehensive monitoring of chemical processes, mitigating risks and ensuring compliance with safety standards. In general automation, it provides scalable solutions for factory automation systems, supporting everything from robotic arms to conveyor belt synchronization with unmatched reliability. When compared to other Rolls-Royce automation products such as the Rolls-Royce WRC1021B and Rolls-Royce MEC210, the UPR-86867 demonstrates superior processing speed and a higher density of input/output channels, offering greater system flexibility and scalability. Unlike the Rolls-Royce M2202 and Rolls-Royce H1127-0101, which focus primarily on specific control applications, the UPR-86867 delivers a more versatile platform suitable for a broader range of industrial scenarios.

The Rolls-Royce UPR-86867 also outperforms models like the Rolls-Royce Control Remoto and Rolls-Royce CP07-311 in terms of environmental resistance and operational uptime, making it a preferred choice for mission-critical automation tasks. Alongside the Rolls-Royce UPR-86867, customers can also consider complementary products such as the Rolls-Royce 222-653 Plc2001b.PCB for enhanced programmable logic control, the Rolls-Royce SBP001 for specialized sensor integration, and the Rolls-Royce Loop Thruster for dynamic process adjustments in automation systems. The Rolls-Royce GWY 01 and Rolls-Royce GWY11 serve as excellent communication gateways, facilitating seamless data exchange between automation components. Additionally, the Rolls-Royce MPCF1-10.4" offers intuitive human-machine interface capabilities, while the Rolls-Royce Load Control DQ96-c ensures optimized power distribution within automated processes. For remote operation scenarios, the Rolls-Royce Remote Control System Node integrates smoothly with the UPR-86867, enabling centralized command and monitoring. The application of the Rolls-Royce UPR-86867 in power industry, petrochemical, and general automation is further enhanced by its compatibility with existing Rolls-Royce infrastructure, including models like the Rolls-Royce H1111.0104 and Rolls-Royce 5880-pc1002 Rev.A, ensuring a cohesive and scalable automation ecosystem.

This interoperability reduces integration complexity and accelerates deployment timelines, empowering industries to achieve operational excellence swiftly. In summary, the Rolls-Royce UPR-86867 is a state-of-the-art automation solution designed to address the multifaceted needs of demanding industrial environments. Its combination of high input/output capacity, durability, and rapid processing performance sets it apart from other Rolls-Royce automation products. Whether deployed in power plants, petrochemical refineries, or automated manufacturing lines, the UPR-86867 delivers unmatched reliability and precision. By integrating seamlessly with complementary Rolls-Royce models like the WRC1021B, MPCF1-10.4", and Remote Control System Node, it forms the backbone of advanced control systems, driving efficiency and safety in critical applications. For industries seeking robust, high-performance automation technology, the Rolls-Royce UPR-86867 remains the definitive choice.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-