Rolls-Royce Upr-86982 - Gs-hydro 332116 Block Tee 3000 Psi

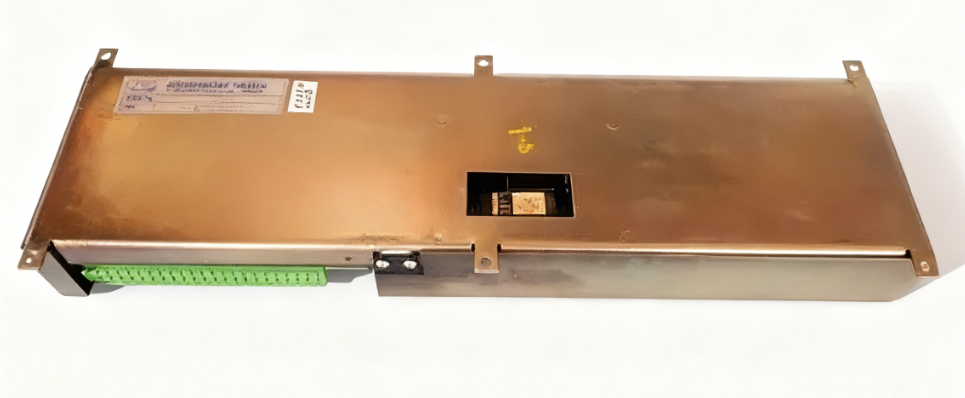

The Rolls-Royce Upr-86982 stands out as a premier solution within Rolls-Royce automation products, designed specifically to meet the rigorous demands of the power industry, petrochemical sector, and general automation applications. Engineered with precision, this model delivers exceptional input/output capacity, high durability, and unmatched performance metrics, making it an indispensable asset in complex industrial environments. At the core of the Upr-86982’s technical excellence lies its robust input/output framework, capable of handling extensive signal processing with minimal latency. This ensures seamless integration with a variety of control systems, enabling real-time responsiveness crucial for automation tasks. The high-density I/O modules support diverse analog and digital signals, providing flexibility and scalability to accommodate evolving operational needs. Coupled with advanced internal diagnostics and fault-tolerant architecture, the Upr-86982 guarantees continuous uptime and reliability, significantly reducing operational disruptions. Durability is another hallmark of the Upr-86982. Constructed with industrial-grade materials and designed for harsh environments, it withstands extreme temperatures, vibrations, and corrosive atmospheres commonly found in petrochemical plants and power generation facilities.

Its rugged enclosure conforms to stringent IP ratings, ensuring protection against dust and moisture ingress, further solidifying its suitability for demanding automation applications. Performance-wise, the Upr-86982 excels with rapid data throughput and precise control capabilities. It supports multi-protocol communication, facilitating interoperability with legacy and modern systems alike. This versatility enables it to function optimally in both new installations and retrofit projects. The model’s low power consumption combined with high processing power underscores its efficiency, aligning with sustainability initiatives in industrial automation. In real-world scenarios, the Rolls-Royce Upr-86982 is frequently deployed in power plants where reliable automation is critical for load balancing, turbine control, and safety interlock systems. In the petrochemical industry, it manages complex process control loops, ensuring safe and efficient operation of reactors, distillation columns, and compressor stations. Its adaptability also extends to general automation, where it orchestrates manufacturing lines, robotic systems, and energy management solutions, demonstrating its broad applicability. When compared to other models within the Rolls-Royce portfolio, the Upr-86982 offers distinct advantages.

Unlike the Rolls-Royce MPC200, which focuses primarily on modular control tasks, the Upr-86982 provides enhanced I/O capacity and superior environmental resistance, making it more suitable for outdoor or harsh facility conditions. Compared to the Rolls-Royce UN41 and UN71 units, which serve as standard automation controllers, the Upr-86982 delivers higher processing speeds and improved fault diagnostics, reducing downtime. Additionally, against the Rolls-Royce Loop Thruster Control and Loop Thruster models, which specialize in marine and dynamic positioning applications, the Upr-86982’s design is optimized for fixed industrial installations demanding robust process automation. Alongside the Rolls-Royce Upr-86982, we also offer complementary models such as the Rolls-Royce MEG-100-101-102 series for advanced monitoring, the Rolls-Royce HCX LF80-01-20 for high-frequency signal processing, and the Rolls-Royce Lauer LCA 325.P2 which excels in precision control tasks. The Rolls-Royce ED725881 provides excellent interface capabilities, perfectly pairing with the Upr-86982’s extensive I/O options. For specialized instrumentation, the Rolls-Royce Eurotherm 2408 offers temperature control solutions that integrate seamlessly within automated systems utilizing the Upr-86982.

The Rolls-Royce RPM40017 and Rolls-Royce SBP001 models further enhance rotational speed monitoring and process balancing functions, respectively. Meanwhile, the Rolls-Royce CCP-FPGI and Rolls-Royce HCX-TT provide FPGA-based processing and timer functionalities that complement the Upr-86982’s core operations. The application of Upr-86982 in power industry, petrochemical, and general automation environments is a testament to its versatility and reliability. Its ability to maintain operational integrity under extreme conditions while delivering precise control makes it a preferred choice for engineers and plant managers focused on optimizing performance and safety. In summary, the Rolls-Royce Upr-86982 is a benchmark automation controller that combines high input/output capacity, industrial-grade durability, and exceptional performance. Its seamless integration with other Rolls-Royce automation products, such as the MPC200, MEG-100 series, and Loop Thruster Control systems, ensures a comprehensive automation ecosystem tailored to the most demanding industrial applications. Whether deployed in power generation, petrochemical processing, or broader automation tasks, the Upr-86982 empowers facilities to achieve greater efficiency, reliability, and operational excellence.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-