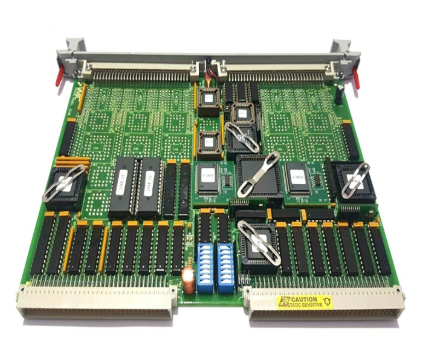

GE VMIVME2540 is an industrial grade intelligent counter module based on the VME bus architecture launched by General Electric (GE). As an important member of GE's VME series of automation products, its core model is VMIVME2540. This module is designed specifically for high-precision counting and signal processing requirements in industrial sites, integrating composite functions such as multi-channel counting, frequency measurement, and pulse capture. It can collect and accurately calculate various pulse signals and event signals in real time, and is widely used in automation control scenarios such as production line speed measurement, workpiece counting, and equipment positioning in manufacturing, energy, transportation, and other fields. It provides reliable support for digital monitoring and precise control of industrial systems.

GE VMIVME2540 Intelligent Counter

Basic Product Information

GE VMIVME2540 is an industrial grade intelligent counter module based on the VME bus architecture launched by General Electric (GE). As an important member of GE's VME series of automation products, its core model is VMIVME2540. This module is designed specifically for high-precision counting and signal processing requirements in industrial sites, integrating composite functions such as multi-channel counting, frequency measurement, and pulse capture. It can collect and accurately calculate various pulse signals and event signals in real time, and is widely used in automation control scenarios such as production line speed measurement, workpiece counting, and equipment positioning in manufacturing, energy, transportation, and other fields. It provides reliable support for digital monitoring and precise control of industrial systems.

Core specification parameters

Core model

VMIVME2540

Product Type

VME bus intelligent counter module

Bus standard

Compatible with VMEbus Rev. C. 1 specification, supporting 16 bit/32 bit data transmission

Counting channel

8 independent counting channels, supporting multi-channel synchronous operation

Counting range

32-bit unsigned integer, counting range 0~4294967295

Input signal type

Differential TTL/RS-422 signal, supports positive/negative edge triggering, strong anti-interference ability

Maximum counting frequency

Single channel up to 10MHz, meeting high-speed signal counting requirements

power supply voltage

VME bus standard power supply,+5V DC (typical value), power consumption ≤ 5W

Working temperature range

0 ℃~60 ℃, suitable for industrial computer rooms and on-site control environments

Storage temperature range

-40 ℃~85 ℃, convenient for transportation and inventory management

Performance characteristics

-High precision multi-channel counting: The 8-channel independent channel design supports parallel counting, with a 10MHz high-speed counting frequency and 32-bit counting accuracy, which can accurately capture high-speed pulse signals and effectively avoid counting loss or errors. It is suitable for scenarios such as workpiece counting and motor speed measurement in high-speed production lines.

-Rich working modes: Supports multiple working modes such as incremental counting, decremental counting, bidirectional counting, frequency measurement, cycle measurement, pulse width capture, etc., which can be switched through software configuration to meet the diverse measurement needs of different industrial scenarios.

-Flexible triggering and interruption mechanism: Each channel can independently set counting thresholds, compare triggering conditions, support overflow/underflow interrupts, threshold matching interrupts, external triggering interrupts, and other types of interrupts. The response time is ≤ 1 μ s, and the control system can be quickly linked to perform subsequent operations.

-Strong anti-interference ability: The input signal adopts differential isolation design, which can effectively suppress common mode interference and electromagnetic interference in industrial sites; The module integrates power filtering and signal shaping circuits to ensure counting stability in complex electromagnetic environments.

-Convenient programming and integration: Provides a standard VME bus interface function library, supports mainstream programming software such as C/C++and LabVIEW, and is compatible with GE and third-party VME bus control systems; The module comes with onboard configuration memory, which can save working parameters and automatically restore configuration after power on, reducing system startup time.

-Reliable structural design: adopting standard 3U VME board size, complying with industrial grade mechanical specifications, supporting rail installation and rack fixation; High reliability industrial grade chips are selected for the components, with an average time between failures (MTBF) of ≥ 100000 hours.

Applicable scenarios

The VMIVME2540 intelligent counter, with its high precision, multi-channel, and strong anti-interference characteristics, is widely used in various industrial automation control scenarios, mainly including:

1. Manufacturing industry: counting of workpieces in automotive parts production lines, counting of finished products in packaging machinery, and counting of overprinting accuracy detection in printing equipment;

2. Energy industry: measurement of blade speed for wind turbines, monitoring of turbine speed for hydroelectric power plants, positioning and counting of photovoltaic module production equipment;

3. Transportation field: Wheel axle speed counting for rail transit signal systems, lifting height positioning counting for port cranes, and cargo sorting counting for logistics conveyor lines;

4. Metallurgy and chemical industry: measurement of roller speed in steel production lines, monitoring of stirring speed in chemical reaction vessels, and measurement of the running length of conveyor belts;

5. Testing and measurement: Frequency and period measurement of various pulse signals in the laboratory, signal stability testing and counting of electronic devices.

Precautions for use

1. Module installation must comply with the VME bus specification and be operated by professional technicians. Before installation, ensure that the system is powered off to avoid static electricity damage to the module during bus insertion and removal;

2. Shielded twisted pair cables should be used for input signal cables, and the cable length should not exceed 50 meters to avoid parallel laying with power cables and reduce signal interference;

Before the first use, it is necessary to configure the channel working mode, counting threshold, interrupt type and other parameters through programming software. After the parameter configuration is completed, it is recommended to conduct testing and verification;

4. Regularly maintain the module, including checking the tightness of the board connections, cleaning the dust in the board's heat dissipation holes, testing the stability of input signals, and cutting off the system power before maintenance;

When the module experiences counting abnormalities or communication failures, the input signal quality and bus connection status should be checked first, and then the module status register should be read by diagnostic software to troubleshoot the problem;

6. The module should operate within the specified temperature, humidity, and voltage range, avoiding long-term operation in high temperature, high humidity, and strong vibration environments. Specific parameters are subject to the official GE manual.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-