IS215VPROH2BC is the core turbine protection board of the VPROH2B series launched by GE, specifically designed for the safe operation of large industrial and power generation turbines. It is an indispensable key component in the turbine control system. This product is developed based on GE's mature industrial control technology platform, with high reliability, strong anti-interference ability, and precise signal processing performance. It can monitor the operating status of the steam turbine in real time, quickly trigger protection mechanisms in case of abnormal working conditions, avoid equipment damage and safety accidents, and provide solid guarantees for the stable operation of the steam turbine.

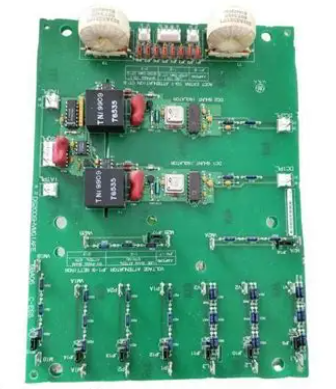

GE VPROH2B IS215VPROH2BC turbine protection board

Product Overview

IS215VPROH2BC is the core turbine protection board of the VPROH2B series launched by GE, specifically designed for the safe operation of large industrial and power generation turbines. It is an indispensable key component in the turbine control system. This product is developed based on GE's mature industrial control technology platform, with high reliability, strong anti-interference ability, and precise signal processing performance. It can monitor the operating status of the steam turbine in real time, quickly trigger protection mechanisms in case of abnormal working conditions, avoid equipment damage and safety accidents, and provide solid guarantees for the stable operation of the steam turbine.

As a supporting module for mainstream steam turbine control systems such as GE Mark VIe, IS215VPROH2BC is widely used in large steam turbine units in the fields of power, petrochemicals, metallurgy, etc., adapting to the needs of units of different power levels. It is a mature product that has been proven through long-term practice in the field of industrial automation control.

Core functions

1. Multi dimensional state monitoring

This protective board has rich signal acquisition channels and can monitor key operating parameters of the steam turbine in real time, including but not limited to: turbine speed, shaft vibration, shaft displacement, bearing temperature, steam pressure, steam temperature, oil system pressure, etc. By using high-precision AD conversion modules, analog signals are converted into digital signals, providing precise data support for subsequent logical judgments. The monitoring accuracy can reach 0.1% FS, ensuring timely response to subtle changes in the operating status of the unit.

2. Quickly protect logical execution

Built in high-performance microprocessor, pre stored protection logic thresholds for different operating conditions of the steam turbine, such as overspeed protection, low oil pressure protection, shaft vibration over limit protection, shaft displacement over limit protection, etc. When a parameter exceeds the safety threshold, the protection board can complete logical judgment and output protection instructions within milliseconds, triggering emergency shutdown, load reduction, or alarm actions, minimizing the fault response time and reducing the risk of equipment damage. Its protection logic supports personalized configuration based on the characteristics of the unit, meeting the safety requirements of different scenarios.

3. Signal isolation and anti-interference

By adopting photoelectric isolation and electromagnetic shielding technology, the input and output signals are comprehensively isolated and processed, effectively resisting electromagnetic interference, voltage fluctuations and other interference factors in industrial sites, and avoiding false protection or protection failure caused by false signals. The input signal isolation voltage can reach 2500Vrms, and the output signal has short-circuit protection function, further improving the stability and reliability of the product in complex industrial environments.

4. Diagnostic and communication functions

Equipped with comprehensive self diagnostic function, it can monitor the power status, chip working status, communication link status, etc. of the board in real time. When a board failure occurs, it can output diagnostic alarm signals in a timely manner, which is convenient for operation and maintenance personnel to quickly locate the problem. At the same time, it supports data exchange with higher-level control systems (such as DCS, PLC) through standard communication protocols (such as Modbus, Profinet, etc.), uploading monitoring parameters, protection action records, diagnostic information, and other data to achieve centralized monitoring and data traceability of unit operation status.

Technical characteristics

-Power parameters: The input voltage is usually DC 24V or DC 110V (can be configured according to specific needs), the power ripple factor is ≤ 5%, the power consumption is ≤ 15W, and it has overvoltage and overcurrent protection functions.

-Input and output channels: Analog input channels 8-16 (4-20mA or 0-10V), digital input channels 16-32 (dry or wet contacts), digital output channels 8-16 (relay output or transistor output), can meet the signal access requirements of different units.

-Working environment: The working temperature range is 0-60 ℃, the relative humidity range is 5% -95% (no condensation), and the storage temperature range is -40-85 ℃, suitable for harsh environments in industrial sites.

-Mechanical characteristics: It adopts standard rack mounted installation, with dimensions that comply with IEC standards, making it easy to integrate into existing control system cabinets. The installation method is plug-in, making it easy to maintain and replace.

-Certification standards: Through international certifications such as UL and CE, it meets the safety and electromagnetic compatibility standards of industrial control equipment, ensuring the compliant use of products in different regions around the world.

Installation and operation precautions

1. Installation requirements

Before installation, it is necessary to check whether the appearance of the board is intact, whether there are any bent pins, damaged components, etc; During installation, it is necessary to ensure that the cabinet is well grounded with a grounding resistance of ≤ 4 Ω to avoid electrostatic interference; When inserting the board into the rack, align it with the guide rail and gently push it into place to ensure reliable contact and avoid pin damage caused by forced insertion and removal; The installation location should be away from equipment with high temperature, high humidity, and strong electromagnetic interference, such as frequency converters, high-power motors, etc.

2. Key points of operation and maintenance

Regularly clean the board to remove surface dust and prevent poor heat dissipation caused by dust accumulation; Regularly check whether the power and signal wiring of the board is secure, whether there is any looseness or oxidation, and promptly deal with any problems found; Utilize the diagnostic function of the control system to regularly check the self diagnostic information of the board and promptly detect potential faults; If it is necessary to replace the board, it is necessary to ensure that the model and firmware version of the new board are consistent with the original board. After replacement, parameter configuration and functional testing should be carried out to ensure compatibility with the system.

Application scenarios

The IS215VPROH2BC turbine protection plate is widely used in the following scenarios due to its high reliability and precise protection performance:

1. The steam turbine generator unit in thermal power plants serves as the executing component for core protections such as overspeed and low oil pressure;

2. Steam turbines are used in catalytic cracking and ammonia synthesis units in the petrochemical industry to ensure continuous and stable process production;

3. Blast furnace blowers and waste heat power generation turbines in the metallurgical industry to enhance the safety of equipment operation;

4. Auxiliary protection systems for large rotating machinery in other industrial fields, such as gas turbines, water turbines, etc.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-