How to order GE Hydran M2 (Mark III) transformer monitoring equipment?

How to order GE Hydran M2 (Mark III) transformer monitoring equipment?

Equipment Overview

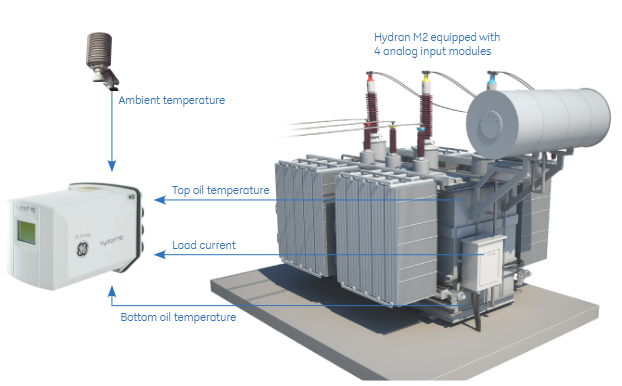

Hydran ™ M2 is a continuous online dissolved gas and oil moisture monitoring device for transformers, which can alert staff of faults in transformers, provide critical monitoring information, and reduce the risk of unplanned power outages. By connecting additional sensors, more information can be obtained and correlated with DGA and moisture values for in-depth analysis of transformer status. Its data can be transmitted as raw data through various communication methods, and can also be transmitted using IEEE based methods ® The on-board calculation of standard transformer mathematical models is converted into useful information.

Main advantages

Continuously measure the dissolved fault gases and moisture in the oil for early identification before potential problems develop into serious transformer faults.

Gas sensors can be selected: traditional "composite gas" sensors or more basic "hydrogen only" sensors.

Built in transformer model calculation based on IEEE standards (only applicable to mineral oil).

Multiple communication options and protocols for easy integration into SCADA or DCS systems.

The validated third-generation design has a large installation base worldwide.

Support new low flammability ester oils and mineral transformer insulation oils.

Application scenarios

Power company: Provide integrated solutions for important medium-sized transformers, focusing on and prioritizing asset replacement strategies.

Industrial factories: Reduce the risk of process interruptions caused by power failures and minimize costly production downtime.

Asset supervision: Easy to permanently install on a single transformer oil valve, without the need for additional pipelines or pumps, and can choose to input other sensors; Only hydrogen "or" composite gas "sensors are optional, where the" composite gas "sensor responds 100% to hydrogen (general fault gas) and is sensitive to carbon monoxide (paper), acetylene (arc), and ethylene (oil); The moisture sensor measures water in the oil, which is the result of insulation paper degradation (producing carbon monoxide and water) or gasket leakage.

Configurable alarms

When abnormal levels of faulty gas or moisture are detected, an alarm can be triggered with two alarm levels (one for warning and one for alarm) to indicate an increase in severity.

The alarm can also be set on the value of the optional analog input card or on the optional calculated transformer model.

Automatic self check every 15 days, and if a fault is detected (including power failure, oil valve closure, sensor failure), a service alarm will be triggered.

Mark III improvements

A thorough overhaul was conducted to improve the durability of the sensor, and new electronic boards and power supplies were used to comply with RoHS standards, while also enhancing the reliability and performance of the equipment.

Suitable for transformers using mineral insulating oil, now also suitable for ester oil (natural or synthetic).

GE's highly acclaimed Perception ™ Software compatibility, downloadable, trend analysis, and analysis of transformer data.

Transformer model

Hydran M2 provides a mathematical model of mineral oil transformers based on IEEE standards and relevant to on-site experience. Using available sensor inputs, the received data is converted into useful real-time information to further understand the overall health status of the transformer. Possible model output examples include: estimating winding hotspot temperature, moisture content in paper, moisture bubble temperature, insulation aging, overload capacity, cooling efficiency, OLTC temperature difference.

Technical specifications

Measurement: including relevant parameters of composite gas sensors, hydrogen only sensors, and moisture sensors, such as measurement range, accuracy, response time, relative sensitivity, repeatability, etc.

Function: Equipped with a backlit LCD display screen (128 x 64 pixels) and a keyboard for setting devices and confirming alarms; Equipped with digital communication methods such as RS-232 port and RS-485, supporting multiple protocols; There are 5 different alarms that can be set on multiple parameters, equipped with 5 dry contact relays; Equipped with an easily accessible external oil sampling port.

Environment: The working environment temperature is -40 ° C to+55 ° C, and the working environment humidity is 0-95% RH (non condensing). When equipped with a finned radiator adapter option, the oil temperature at the valve is -40 ° C to+105 ° C, and the oil pressure at the valve is 0-700KPa (vacuum resistant sensor).

Shell rating: NEMA Type 4X certified, compliant with IP56 requirements.

Power requirements: 90-132 Vac or 180-264 Vac switch mode universal power supply, 47-63 Hz, maximum 650VA.

Mechanical parameters: It has a 1.5-inch NPT external thread and can be installed on 1-inch or 2-inch NPT internal thread valves using optional adapters; The size is 315 x 219 x 196 mm (12.4 x 8.63 x 7.72 inches); The installation weight is 7.5Kg (16.5lb); The transportation weight is 9.0Kg (20lb).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor