Watlow PPC-2000 System Deployment and Configuration Guide

Watlow PPC-2000 Industrial Multi loop PID Control System

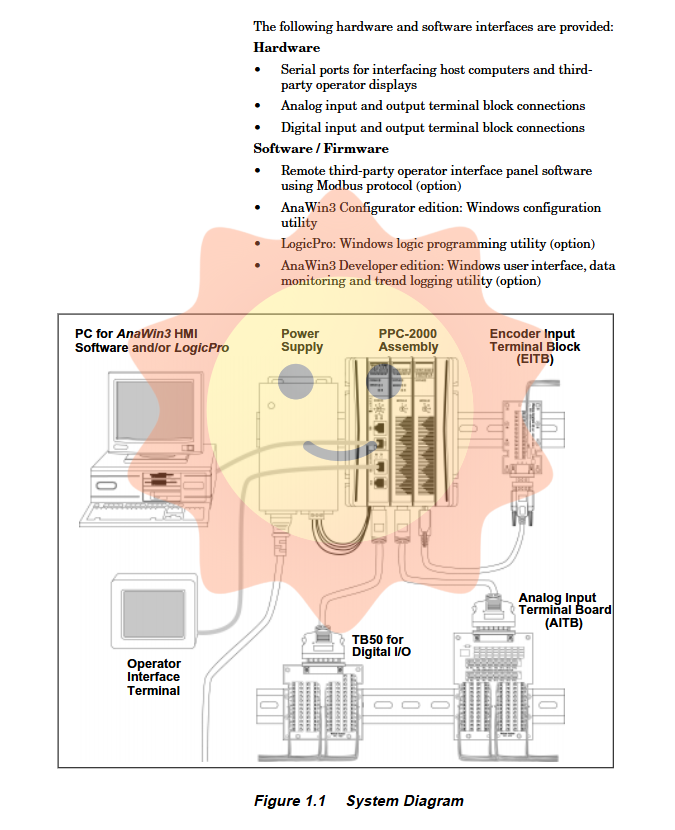

Watlow PPC-2000 is a high-performance modular multi loop PID control system designed specifically for high-precision, multi-channel heat treatment or process control applications. The system supports up to 48 independent PID control loops and can modularly expand digital I/O, analog input, and encoder interfaces to meet complex industrial automation requirements. This document is based on the PPC-2000 User Guide and provides a detailed introduction to its system architecture, hardware installation, software configuration, adaptive control functions, and troubleshooting methods.

1. System architecture and core components

PPC-2000 adopts modular design, allowing users to flexibly configure the system according to specific I/O points and control requirements. The core components include:

Processor module (PPC-2010): The core of the system, including a microprocessor, Flash EPROM, and battery backup RAM. Supports up to 48 loop controls, built-in 48 digital I/O points, and two isolated serial communication ports (RS-232/485).

Analog input module (PPC-2021~2025): supports thermocouple (T/C), RTD (resistance temperature detector), and linear voltage/current signals. Provide differential or single ended input with high isolation options to reduce noise interference.

Digital I/O Module (PPC-2040): Provides up to 32 configurable digital inputs or outputs, as well as two counter/frequency inputs.

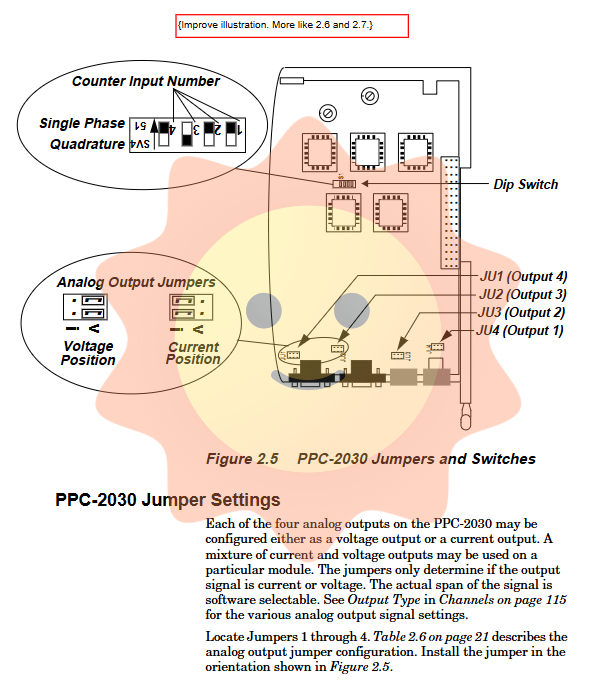

Analog output module (PPC-2050/2051): Provides high-precision voltage or current output for driving external analog devices.

Relay output module (PPC-2061/2062): used to drive electromechanical loads, providing up to 16 relay contacts.

Terminal board (TB50, AITB, EITB): used for on-site wiring, installed using DIN rails or panels, simplifying wiring and module connections.

2. Hardware installation and wiring specifications

Proper hardware installation is the foundation for ensuring the long-term stable operation of the PPC-2000 system.

Module address configuration: Each module (except for processor modules fixed at address 0) must have a unique address set. Use the rotary switch on the panel to set the address, ensuring that the address is correct and conflict free before the system runs. If you want to change the address or module quantity, you need to perform a RAM clearing operation before booting up.

Power connection: The system requires 10-28 VDC power supply. We recommend using the Watlow IPS-2 power supply, which supports an input range of 88-132 Vac or 176-264 Vac (47-440 Hz). Be sure to ground correctly, connect the+V terminal of the processor to the positive pole of the power supply, and connect the C terminal to the negative pole of the power supply.

Grounding and shielding: To avoid EMI (electromagnetic interference) and RF noise, shielded twisted pair cables must be used to connect the sensor, and the shielding layer should only be grounded at one end of the controller. Do not ground the analog common terminal to the ground to avoid damaging the input circuit beyond the protection range.

RC buffer network: When using electromechanical relays or switches to sense loads, it is necessary to parallel the RC buffer network (recommended to connect a 0.47 μ F capacitor in series with a 120 Ω resistor) at both ends of the relay contacts to suppress arcing and noise, and prevent the controller CPU watchdog from timing out.

3. Software configuration and AnaWin3 HMI

AnaWin3 software is used for configuring and monitoring PPC-2000. Through the spreadsheet interface, users can easily set input, channel, alarm, and digital I/O parameters.

Control mode configuration: The system supports PID1 (single output heating or cooling), PID2 (dual output simultaneous control, commonly used for plastic extruders), and on/off control. The PID parameters include proportional band (PB), integration time (TI), and differentiation time (TD).

Advanced control functions:

Cascade control: suitable for systems with long lag times, where the output of the main channel is used to adjust the set point of the slave channel. Suitable for two zone temperature control or aluminum die-casting applications.

Proportional control: calculated from the set point of the channel by multiplying the process variable of the main channel by the proportional coefficient and the offset.

PV retransmission: allows the analog input signal to be linearly scaled and resent through digital or analog output for connecting to a chart recorder.

Lag Curve: Provides non-linear output scaling (Lag Curve A/B) to compensate for the non-linear response of the system to the output device, commonly used in extruder applications.

4. Adaptive control function

For specific models PPC-2010-xxB, the system provides unique adaptive control functions, which can provide 8 adaptive circuits on the basis of the standard version (plus 24 standard circuits, a total of 32 circuits). Adaptive algorithms can adjust PID parameters in real-time to adapt to changes in load characteristics.

Set parameters:

Plant Delay: Refers to the delay time (in seconds) of the load. A larger delay means that as the heater power increases, it takes longer for the temperature to rise. It can be set to "Automatic" for measurement by the controller or manually input.

Tuning Gain: The degree to which the control algorithm responds to load changes in terms of recovery speed. Optional options include "aggressive", "nominal", or "damped", Damped 1-4)。

Adaptive Mode: includes "Adapt" (adapt, normal control), "Reset" (reset, relearn load characteristics), and "Hold" (pause learning but retain current parameters).

Enabling condition: Only channels 1 to 8 can be set to adaptive control. The system must be in automatic mode, and process variables typically need to be at least 40 engineering units below the set point to initiate learning.

5. Communication and Modbus Protocol

PPC-2000 supports Modbus RTU protocol and can be used as a slave to connect to the host or human-machine interface.

Network address: Supports up to 32 PPC controllers for networking. Addresses 1-4 can be set through the panel rotary switch, while addresses 5-32 need to be set through PPCComSu software and the switch should be placed in position 'D'.

Interface selection: Supports RS-232 (point-to-point,<50 feet) and RS-485 (multi-point,>4000 feet). It is recommended to use 4-wire shielded twisted pair for RS-485 wiring and connect 120 Ω terminal resistors at both ends of the network.

6. Troubleshooting and maintenance

The system provides a variety of LED status indicators for diagnosis.

Processor module (PPC-2010): The green LED indicates the normal state when the logic program stops; Quick flashing indicates that the logic program is running; The orange LED indicates a watchdog timeout or low voltage error.

Analog input module (PPC-202x): The red LED light on indicates an open sensor or RTD open circuit; Flashing indicates common mode voltage overload.

Common handling:

If communication is not possible, check for address conflicts, baud rate settings, and termination resistance.

If the system crashes, try shutting down and restarting or performing RAM clearing (set the processor switch to 'E' and then back to 'D').

If the digital I/O status is incorrect, check the polarity of the wiring and the external power supply voltage (matching the controller common terminal).

7. Environmental specifications

Working temperature: 0 ° C to 60 ° C.

Relative humidity: 10% to 95% (non condensing).

Altitude: up to 2000 meters.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor