TOSVERT VF-AS3 series 600V industrial frequency converter

TOSVERT VF-AS3 series 600V industrial frequency converter: in-depth technical analysis and comprehensive application guide

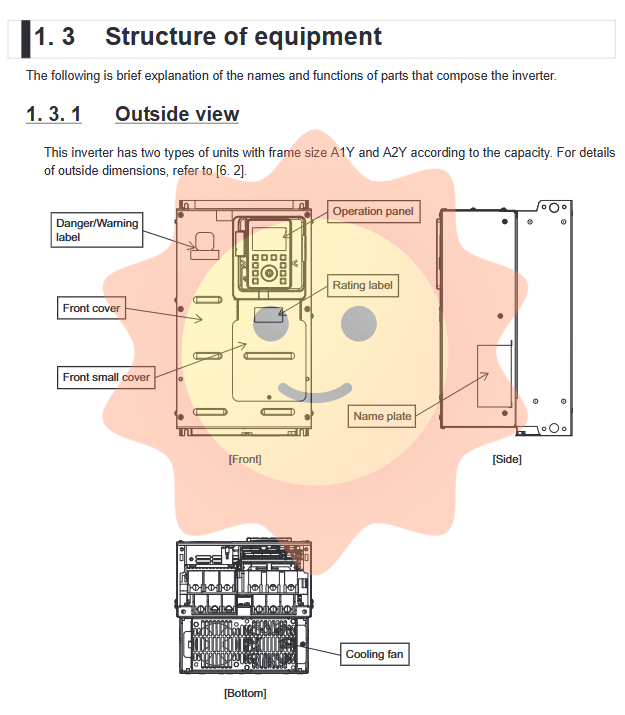

In the field of industrial automation and motor control, the performance, reliability, and safety of frequency converters are crucial as the core driving equipment. Toshiba's VF-AS3 series industrial frequency converters are designed specifically for three-phase induction motors, built-in and surface mounted permanent magnet synchronous motors, and are suitable for a wide range of industrial scenarios. This article is based on the official technical manual, providing a systematic and professional technical analysis and application explanation of the 600V level products in this series. It covers key content such as product overview, safety specifications, installation and wiring, parameter settings, compliance standards, and maintenance, aiming to provide a comprehensive and in-depth reference guide for engineering design, installation, commissioning, and maintenance personnel.

Product Overview and Core Design Philosophy

The VF-AS3 series frequency converter is a high-performance motor driver designed for general industrial applications. The core design concept is to provide a flexible, efficient, and safe motor speed control solution. The product supports multiple voltage levels of 500V, 600V (575V), and 690V, and has multiple rated value selection functions. Users can choose between heavy load or normal load rating based on load characteristics (constant torque or variable torque), thus achieving the best matching and application optimization of the equipment. This series of products adopts sine wave PWM control technology, providing precise frequency and torque output, and built-in rich control functions such as PID regulation, multi-stage operation, automatic torque boosting, etc., to meet complex process requirements.

Critical safety operation standards

Safety is the primary prerequisite for the use of equipment. The manual prominently emphasizes safety precautions and adopts the internationally recognized three-level identification system of "warning", "caution", and "prompt" to clarify the possible consequences of different operational errors.

Electrical safety: It is strictly prohibited to remove the front cover or contact terminals while powered on. There are high-voltage components inside, which pose a fatal risk of electric shock. Before any wiring or maintenance, all input power must be cut off and wait for at least 15 minutes until the charging indicator light goes out, and use an instrument to confirm that the DC bus voltage has dropped to a safe level (below 45V DC).

Fire prevention and equipment safety: It is forbidden to connect the power supply to the motor output terminal, and it is forbidden to incorrectly connect the braking resistor between the DC terminals, otherwise it may cause equipment damage or fire. Suitable short-circuit protection devices and ground leakage protectors must be installed on the power supply side. The frequency converter needs to be installed on a metal backplate, away from flammable materials and liquids.

Personal and mechanical safety: Two or more people are required to cooperate when transporting aircraft weighing over 20kg, and a crane is required for heavy machinery. The installation location should be able to withstand the weight of the equipment and avoid high vibration environments. During operation or after power failure, the motor may rotate due to inertia and generate high voltage at the output end. Touch is prohibited. Before resetting the fault, it is necessary to confirm that the operation command has been turned off to prevent accidental motor start-up and injury.

Environmental and usage restrictions: Clearly state that the product is suitable for general industrial use and cannot be used in situations with special safety requirements such as nuclear energy, aviation, life support, etc. It is strictly prohibited to drive single-phase motors.

Installation, wiring, and environmental requirements

Correct installation and wiring are the foundation for ensuring the long-term stable operation of the frequency converter.

Installation environment:

Temperature: The operating environment temperature ranges from -15 ° C to+60 ° C. When the ambient temperature exceeds 50 ° C, the rated output current needs to be reduced or the operation panel needs to be removed and installed separately (the operation panel contains a lithium battery, which poses a risk of high temperature).

Humidity and pollution: Relative humidity of 5% -95% (no condensation), pollution level of 2. It should be avoided to install in places with high dust, metal shavings, oil mist, corrosive gases, or where there is a risk of condensation or freezing.

Space and heat dissipation: Adequate heat dissipation space should be ensured during installation. When multiple frequency converters are installed side by side, the minimum spacing is 11mm, but it is recommended to reserve more space at the top and bottom to facilitate air duct circulation. The manual provides detailed heat generation data and calculation tables for the required ventilation volume for forced air cooling of cabinets and the required heat dissipation surface area for sealed cabinets.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor