Watlow MLS Controller Guide

Watlow MLS Multi Loop PID Controller Professional Deployment and Configuration Guide

The Watlow MLS (Modular Loop System) controller is a modular, high-precision multi loop PID control system designed specifically for complex industrial process control. It provides 16 or 32 independent PID control loops, achieving high-performance applications from simple switch control to complex cascade control, slope/insulation programs through flexible combinations of analog input modules (AIM), processor modules (PM), and remote terminal boards (RTB). This document is based on the official user guide and provides a detailed overview of the MLS system's component architecture, mechanical installation specifications, electrical wiring standards, system configuration, and troubleshooting methods. The aim is to provide engineers with a complete set of deployment and configuration references.

1. System architecture and core components

The modular design of MLS system is its core advantage, allowing users to flexibly configure according to their actual needs.

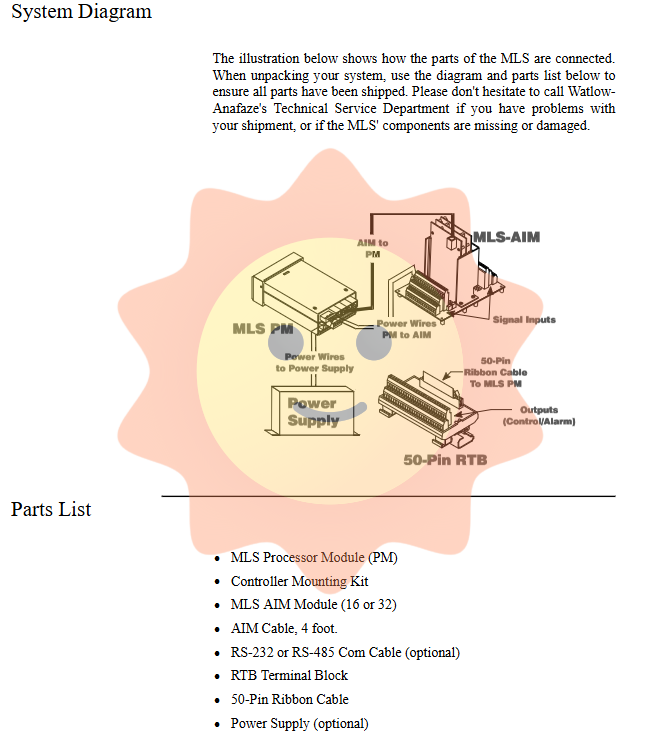

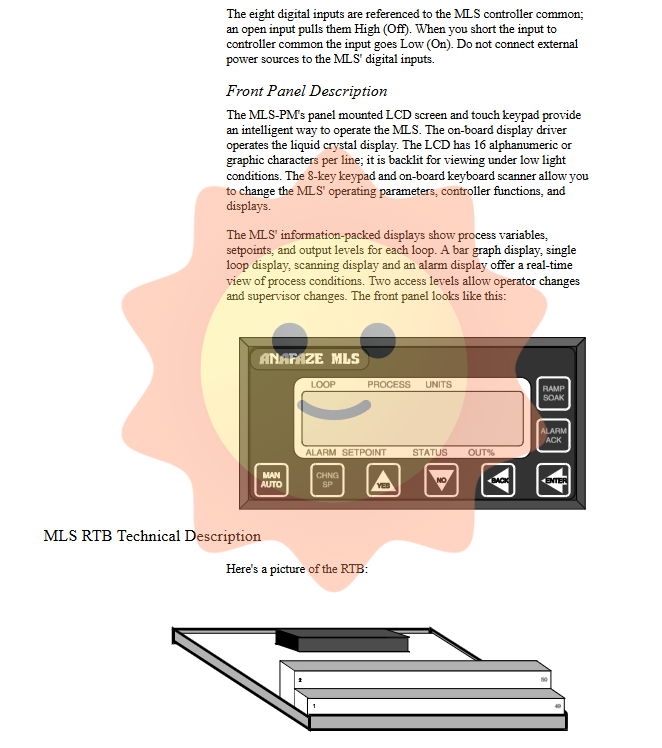

MLS Processor Module (PM): This is the core brain of the system, packaged in a 1/8 DIN panel. It includes a CPU microprocessor, RAM with lithium battery backup, pluggable EPROM (for firmware upgrade), LCD display screen, and touch keyboard. The PM is responsible for performing all PID operations, linearization of input signals, alarm logic, and serial communication. It controls other modules through internal communication cables and connects to RTB through a 50 pin flat cable.

MLS Analog Input Module (AIM): Used to receive sensor signals. The AIM version is divided into AIM-16 (16 loops) and AIM-32 (32 loops). It includes a multiplexing card (MUX) and a voltage/frequency (V/F) conversion card, capable of handling thermocouples, RTDs (resistance temperature detectors), and linear voltage/current inputs. AIM is connected to PM through a dedicated communication cable.

Remote Terminal Board (RTB): This is a 50 pin screw terminal interface board used to connect internal signals of the controller to external field devices. It contains 34 digital outputs (10mA current) and 8 digital inputs.

Power module (PS): Provides DC power to the entire system. It should be noted that according to the revised Addendum of the manual, the output specifications of the new power supply (MLS-PS) are: 15 Vdc (1.2A) for AIM power supply and 5 Vdc (4A) for system digital I/O use; Input 120/240 Vac. When wiring, it is necessary to distinguish the corresponding relationship between the old version (12V) and the new version (15V).

2. Mechanical installation and environmental requirements

Correct mechanical installation is the foundation for ensuring heat dissipation and long-term reliability.

Panel opening: MLS-PM adopts standard 1/8 DIN size. The opening size is 1.89 inches (height) x 3.78 inches (width) (48mm x 96mm), with extremely small tolerances, requiring fine operation with a punching machine or opener, and deburring the edges.

Module installation sequence: It is recommended to install MLS-PM first, as it determines the layout and wiring of other modules.

Heat dissipation and space: The installation location should avoid overheating environments exceeding 50 ° C, excessive dust, and unauthorized contact. Sufficient space must be left around the module for future maintenance and disassembly. For the AIM module, a vertical space of approximately 6 inches (15.24cm) needs to be reserved above for inserting the card.

Grounding: Use grounding ears or conductive contact surfaces to ensure good grounding of the module backplane to suppress common mode noise.

3. Electrical wiring and anti-interference specifications

Electrical connections are crucial for system stability, especially in preventing RFI (Radio Frequency Interference).

Power wiring (following the new specifications):

Connect the "DC COM" terminal of the power supply to the "GND" terminal on the PM.

Connect the "+15V" terminal of the power supply to the "+V" terminal on the PM (note: the old manual labeled it as+12V, while the new version uses 15V).

Insert the AIM communication cable into the corresponding slots (Tel 1) of PM and AIM respectively, paying attention to the direction of the red bar.

After powering on, use a multimeter to measure the "+V" terminal voltage of the PM, which should be between 10-28 Vdc; The "EX" terminal should be 0 Vdc.

Check the "+5V" terminal on the AIM board, the voltage should be between 4.75-5.25 Vdc.

I/O wiring and shielding:

Analog input: Shielded twisted pair or three wire shielded cable (for RTD) must be used. The shielding layer should be grounded at the single end of the controller panel (120Vac ground). It is strictly prohibited to bundle low-voltage signal lines with AC power lines (120/240 Vac) for wiring to prevent induced noise.

Digital output: The control output is of the fill current type, with a reference of+5Vdc. Connect to the negative pole of an external solid-state relay (SSR).

Anti interference (RC buffer network): When using electromechanical relays to drive inductive loads (such as alarm horns, motor starters), contact disconnection can generate RFI, which may cause CPU reset or display flashing. An RC buffer network must be installed in parallel on the normally open contacts of the electromechanical relay coil: a 0.01uF/1000VDC capacitor is connected in series with a 47 Ω/0.5W resistor. This is the most effective way to suppress RFI.

4. Input/output configuration and control mode

MLS supports a wide range of sensors and output types to meet various industrial needs.

Analog input configuration:

Thermocouple: directly connected to J, K, T, S, R, B types. Non grounded thermocouples (T/C leads isolated from protective sleeves) must be used. For specific temperature ranges (such as J-type below 400 ° F), an offset can be set for calibration.

RTD: It is recommended to use a three wire 100 Ω platinum resistor (DIN 43760 curve). Scaling resistors (such as RTD1 configuration: RA=5.49K Ω, RB=11.0K Ω, RC=11.0K Ω) need to be installed on the AIM terminal board.

Linear input (pressure, flow rate, etc.): The input signal is mapped to engineering units using two-point scaling method. For example, inputting 0-10mA corresponds to 0-100 PSI, which needs to be divided to the range of -10 to+60mV through an external resistor, and the corresponding PV value and instrument reading need to be entered in the Setup menu.

Control output type:

TP (time ratio): Simulate analog output by changing the on-off time ratio. Need to set cycle time (1-255 seconds), suitable for driving SSR.

DZC (Distributed Zero Crossing): It determines on/off at the zero crossing point of each AC line cycle, with a very high switching frequency, suitable for fast heating loads.

SDAC (Serial DAC): With optional digital to analog converters, it provides high-precision analog current (4-20mA) or voltage output.

Alarm function: Each circuit can independently set high/low process alarms and deviation alarms. An alarm can activate a single digital output or a configured output.

5. PID control parameter tuning and tuning

The correct PID parameters are the key to achieving stable control.

Control mode: Supports on/off, proportional, proportional integral (PI), and proportional integral derivative (PID). For high-precision requirements, PID mode is usually used.

Parameter starting value:

Proportional Bands (PB): typically set at 5% -10% of the set point. For set points below 1000 ° F, set to 10%; Above 1000 ° F, set to 5%.

Integral time (TI): The recommended starting value is 60 seconds per repetition.

Differential Time (TD): The recommended starting value is 15% of TI. For example, if TI=60s, then TD=9s.

Auto tuning: Select "TUNE" mode in the Setup menu. The controller will automatically make the circuit output 100%, calculate the PID parameters, and automatically switch back to automatic mode.

6. Communication interface configuration (RS-232/RS-485)

MLS supports standard serial communication and can be networked with computers or PLCs.

Interface type: configured as RS-232 (point-to-point, single unit) or RS-485 (multi-point, up to 32 units) through internal jumpers.

RS-485 Connection Specification:

Shielded twisted pair cables must be used.

200 Ω terminal resistors need to be connected to the farthest end of the communication line (computer end) and the farthest controller end (last station) respectively.

If the common mode voltage exceeds 7V, the 5th wire must be used as the common ground connection. Otherwise, a shielding layer can be used (note: the shielding layer at the MLS terminal is not grounded, only grounded at the computer terminal).

Parameter settings: Set the controller address (1-32), baud rate (2400 or 9600), and protocol in the Setup Global Parameters menu.

7. Troubleshooting and System Testing

After system deployment, strict testing is required.

Power test: Confirm that the PM's+V voltage is normal and the AIM's+5V power supply is normal.

Communication test: Confirm that communication between AIM and PM is normal (when AIM communication fails, the controller will switch to manual mode and trigger a global alarm).

I/O test: Use the Manual I/O Test menu to forcibly turn on/off the digital output, and measure the voltage with a multimeter (low level=0V, high level ≈ 3.75-5.5V); Short circuit the digital input and check if the screen status has changed.

Common faults:

Display blank: Check if the power supply is working properly.

CPU reset: It may be caused by RFI interference. Check if an RC buffer network is installed on the external relay line.

AIM communication failure: Check the communication cable connection and attempt to perform a 'No Key Reset' (press and hold the No key to power on).

8. Conclusion

The Watlow MLS controller provides a solid platform for complex industrial furnace temperature control with its modular hardware architecture, powerful PID algorithm library, and flexible I/O configuration capabilities. Following the installation specifications (especially power wiring updates, RC buffering anti-interference) and PID tuning principles in this guide can significantly improve the stability and control accuracy of the system. For engineers seeking high reliability and scalability multi loop temperature control solutions, mastering the deployment and configuration skills of MLS is crucial.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor