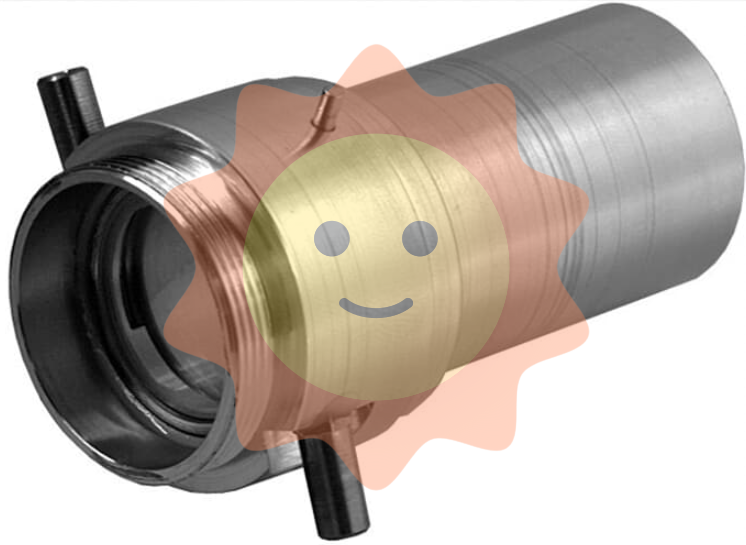

The ABB 0769143 A sample cell is a specialized sample bearing component made of high-quality aluminum alloy material, with a core specification of 175 millimeters (specific key dimensions such as length/diameter, subject to physical and official data). This sample pool, with the excellent characteristics of aluminum alloy material and precise structural design, is suitable for the storage and detection needs of various solid and liquid samples in industrial testing, laboratory analysis, process control and other scenarios. It is particularly suitable for ABB related testing equipment and analysis systems, providing reliable support for stable placement and accurate detection of samples.

ABB 0769143 A Sample cell (Al), 175 mm

Product Overview

The ABB 0769143 A sample cell is a specialized sample bearing component made of high-quality aluminum alloy material, with a core specification of 175 millimeters (specific key dimensions such as length/diameter, subject to physical and official data). This sample pool, with the excellent characteristics of aluminum alloy material and precise structural design, is suitable for the storage and detection needs of various solid and liquid samples in industrial testing, laboratory analysis, process control and other scenarios. It is particularly suitable for ABB related testing equipment and analysis systems, providing reliable support for stable placement and accurate detection of samples.

Core Features

2.1 High quality aluminum alloy material

Made of high-strength and corrosion-resistant aluminum alloy materials, it has superior mechanical strength and environmental corrosion resistance compared to ordinary metal materials. It can effectively resist slight chemical corrosion that may come into contact with the sample during the testing process. At the same time, its lightweight characteristics facilitate the retrieval and installation of the sample pool, reducing operational difficulty.

2.2 Precise structural design

Strictly produced according to ABB standard process, with strict control of dimensional accuracy. The key dimension error of 175mm is controlled within ± 0.5mm (typical value), ensuring that the sample cell can perfectly adapt to the corresponding detection equipment's slot and positioning structure, and avoiding detection data errors caused by installation deviations. The surface of the internal cavity has undergone precision polishing treatment, with a surface roughness Ra ≤ 0.8 μ m, reducing sample residue and facilitating cleaning and maintenance.

2.3 Good compatibility for adaptation

As a standardized accessory of ABB, this sample cell is seamlessly compatible with ABB series testing instruments (such as spectrometers, component detectors, etc., specific compatible models need to refer to the equipment manual), and can be used directly without additional modifications, ensuring the smoothness and stability of the testing process.

2.4 Stable performance

Aluminum alloy material has good thermal stability, with no significant thermal expansion or contraction deformation within the commonly used testing environment temperature range of -10 ℃~80 ℃, ensuring the stability of the sample storage space and providing guarantees for the repeatability and accuracy of testing data.

Key technical parameters

Basic Information

Product Model

ABB 0769143 A

material

Premium aluminum alloy

Dimensions

critical dimension

175 millimeters (specific dimensions subject to official markings)

dimensional accuracy

± 0.5 millimeters (typical value)

Internal cavity volume

Subject to physical and official data

Material Properties

surface roughness

Ra ≤ 0.8 μ m (internal cavity)

corrosion resistance

Resist corrosion from conventional neutral and weakly acidic samples

Usage environment

Applicable temperature range

-10℃~80℃

Applicable humidity range

≤ 85% RH (non condensing)

Installation and usage instructions

4.1 Installation method

The sample pool adopts direct embedded installation. Align it with the sample pool positioning card slot of the detection equipment, gently push it in until you hear a "click" positioning sound to complete the installation. Before installation, it is necessary to ensure that the equipment is in a stopped or standby state, and that there are no debris or stains inside the sample tank and card slot to avoid installation lag or damage to the equipment.

4.2 Sample Placement and Handling

Before placing the sample, it is necessary to confirm that the interior of the sample tank is clean and dry. The dosage should be controlled according to the state of the sample (solid/liquid), and the liquid sample should not exceed 80% of the chamber volume to avoid overflowing and contaminating the equipment during the testing process. For samples with strong corrosiveness and high temperature (exceeding 80 ℃), it is necessary to confirm the tolerance range of the sample pool in advance and prohibit unauthorized use.

4.3 Cleaning and Maintenance

After each use, the sample chamber should be promptly removed, rinsed with clean water or neutral detergent, wiped clean with a dry and dust-free cloth, and stored in a dry and ventilated place. Avoid using hard brushes or corrosive cleaning agents to prevent damage to the surface of the cavity. When not in use for a long time, it is recommended to place moisture-proof paper inside the sample tank to avoid oxidation and corrosion.

Precautions

-It is prohibited to use the sample pool to carry samples beyond its capacity or tolerance range, in order to avoid damage to the sample pool and equipment failure caused by sample overflow, high temperature, or corrosion.

-When installing and taking out the sample pool, it is necessary to handle it gently to avoid violent collisions and prevent deformation or damage to the size accuracy of the sample pool, which may affect the detection effect.

-If the surface of the sample cell is severely scratched, deformed, corroded, or perforated, it should be immediately stopped from use and replaced with a new sample cell, and should not be used for testing work.

-The sample pool is a specialized accessory and should be used in conjunction with the corresponding model testing equipment. It is prohibited to mix it with non ABB equipment or equipment that does not match the model.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-